MARMO PRESETTER

MARMO PRESETTER

The MARMO PRESETTER is an innovative, fully automated device that scans CNC tools with centesimal tolerances, ensuring quick and precise setup.

Thanks to its advanced technology, it allows for accurate tool setup directly on the CNC machine, optimizing setup times, improving machining quality, and extending the lifespan of the tools.

Why process with MARMO PRESETTER?

Using the MARMO PRESETTER allows you to accelerate and optimize the entire tool setup process on CNC machines. Thanks to the automated precision of the scanner, it is possible to achieve a perfect tool setup, ensuring precise configuration on the CNC machine. This not only significantly reduces installation time but also extends the tool’s lifespan by preventing premature wear caused by less accurate manual adjustments.

![]()

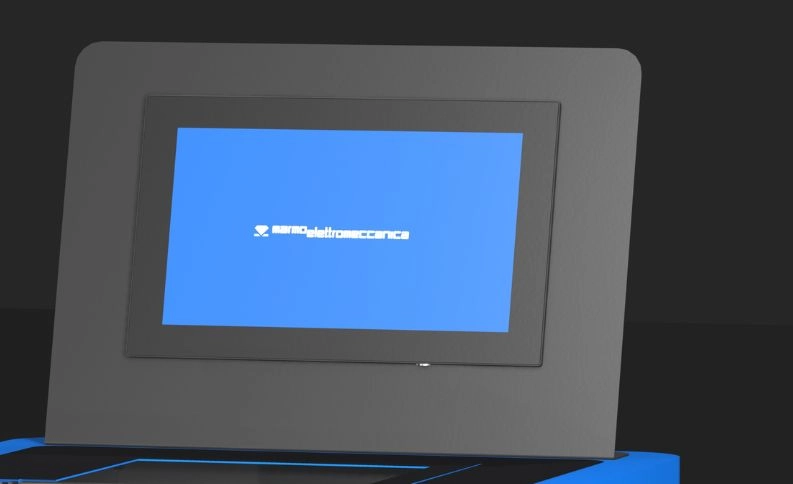

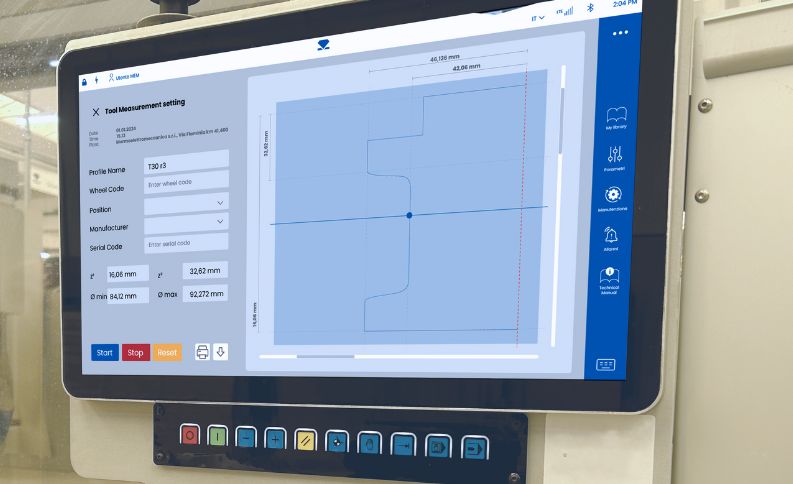

Integrated Panel PC

Large touchscreen with a simple and intuitive inteface.

![]()

User Safety

The movable door ensures user protection.

![]()

Dual Voltage

Operates at both 110V and 220V for maximum adaptability.

![]()

Stepper Motor

High energy efficiency, longer lifespan, and consistent performance in all operating conditions.

![]()

Smart Camera

Next-generation smart camera with Z-axis movements for fast and precise scanning.

![]()

Advanced Features

Advanced remote access via smartphone and full integration with CNC machines.

Main Functions

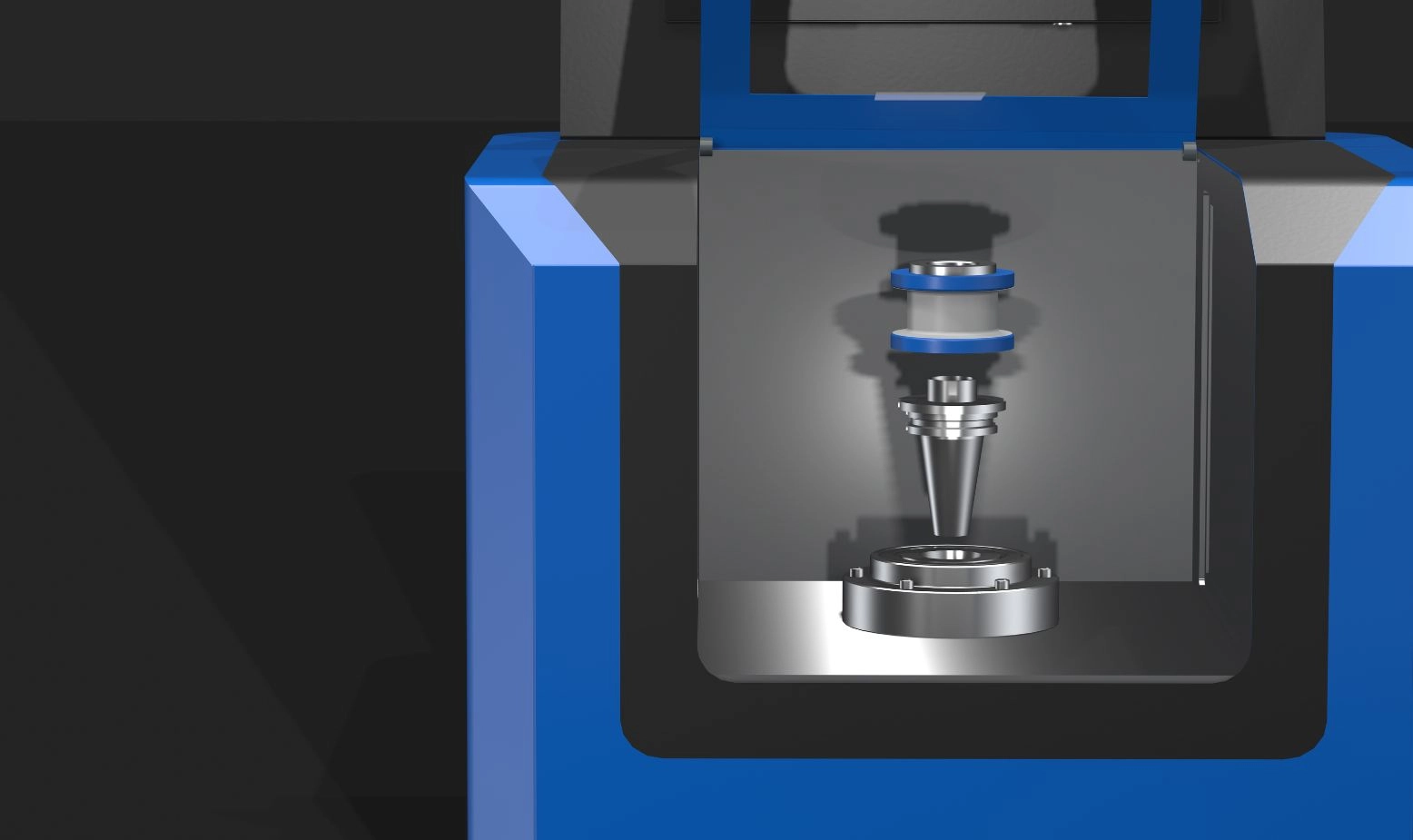

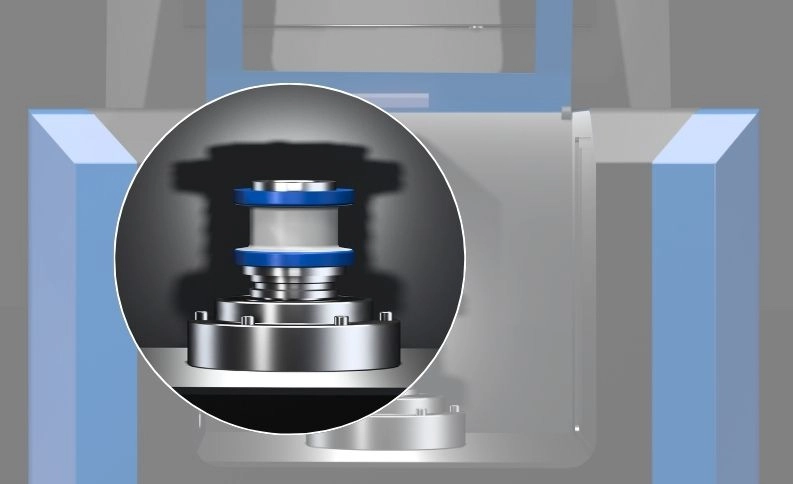

Profile Wheel

Thanks to the CNC ISO40 cone, the manual insertion of the tool is extremely simple and safe. Once positioned, the tool automatically rotates 360 degrees to allow a complete and precise scan of the entire profile diameter, even with the most complex geometries.

Smart Camera

The next-generation smart camera performs thousands of scans per second, ensuring centesimal precision. Its automatic movement along the Z-axis allows for detailed scanning of the tool at different heights, providing a complete and precise profile in extremely short times.

Display 15,6″ – Touch Screen

The system features a large display with a user-friendly interface that enables simple and intuitive management. The user can control and monitor all system functions as easily as using a smartphone, making the process extremely straightforward.

Protective Door

During tool scanning, the protective door ensures maximum user safety and protection against dust. The transparent part of the door allows for monitoring of the tool inside, providing visibility without compromising safety.

Automatic Movements

The MARMO PRESETTER is fully automated.

ROTATION ON ISO CONE 4O: Once the scanning process is started, the tool automatically rotates 360°, allowing for a complete scan of the entire wheel diameter.

SMART CAMERA: The next-generation Smart Camera automatically moves along the Z-axis. This movement allows for scanning the entire tool profile, covering all heights with extreme precision. All operations are managed through the CNC system, offering a fast and fully automated process.

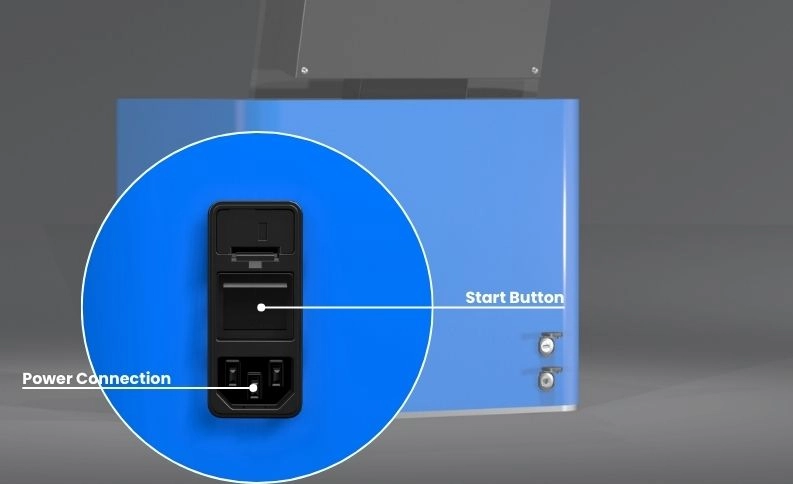

Power On and

Connections

Start Button and Power Connection

The machine is equipped with a simple Start and Stop button, allowing it to be turned on or off with a single gesture. The power connection uses a standard PC monitor cable and supports both 220V and 110V, ensuring flexibility and adaptability to different operational contexts.

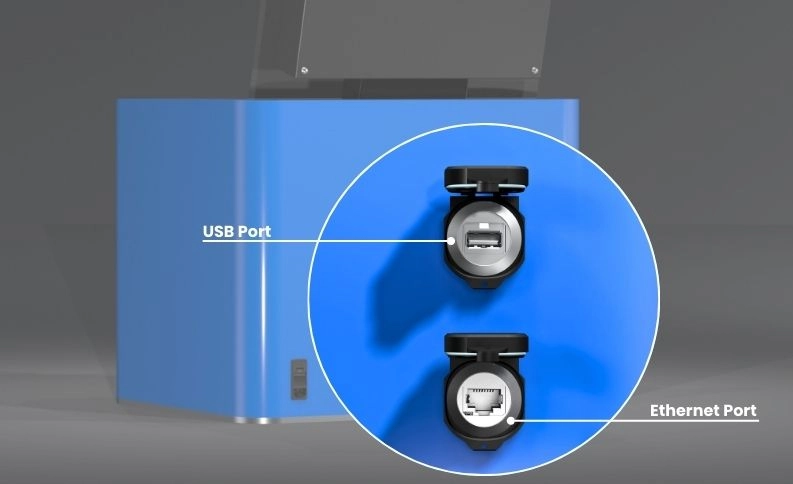

USB & Ethernet Port

The machine is equipped with a USB port for connecting devices such as printers or external storage. Additionally, the Ethernet port allows the machine to connect to the internet for software updates and remote assistance.

Numerical Control

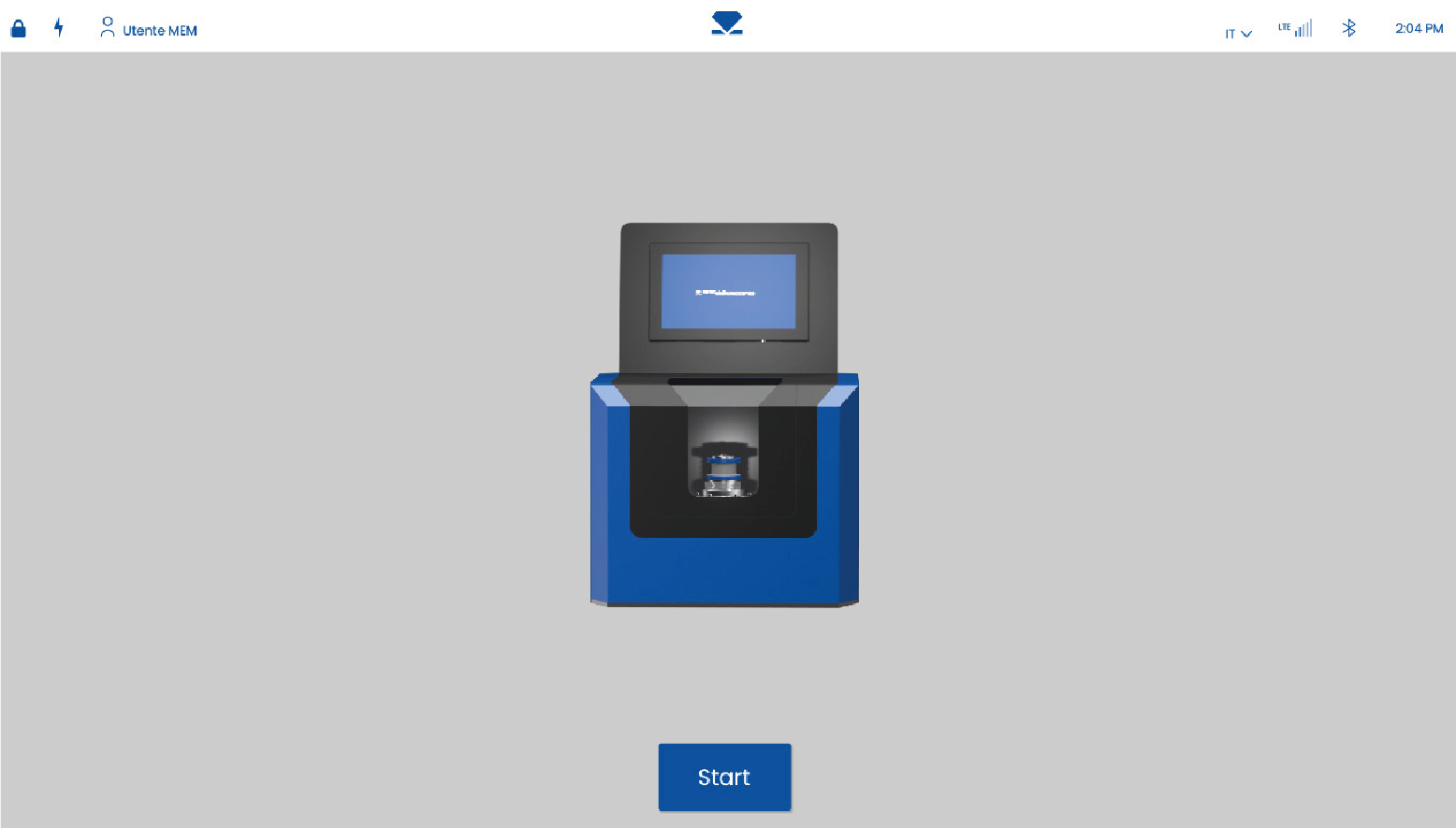

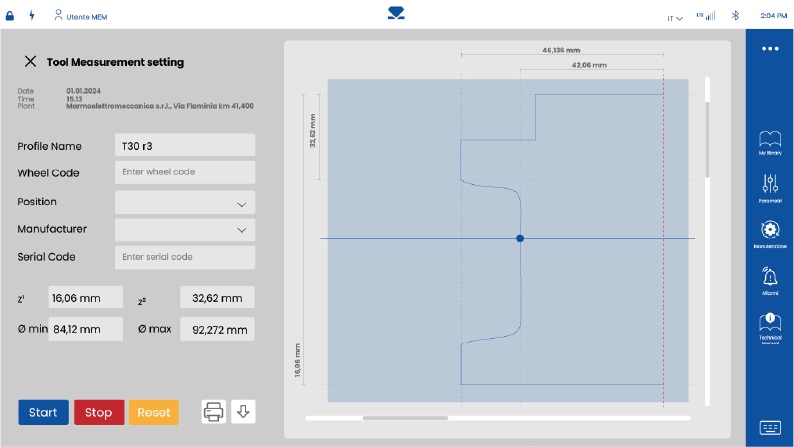

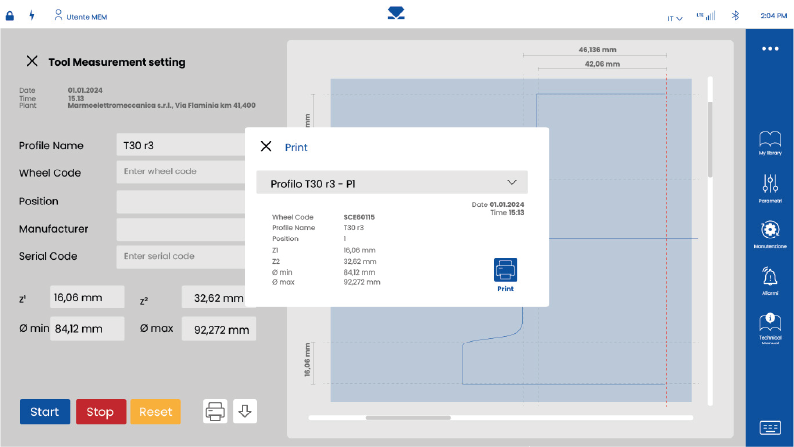

Software Interface

The MARMO PRESETTER is fully automated thanks to CNC software that manages every operation precisely and without manual intervention, revolutionizing the production process.

With a range of integrated features, the machine automatically handles every operation, from setting tool profiles to scanning and measurement, ensuring extreme accuracy.

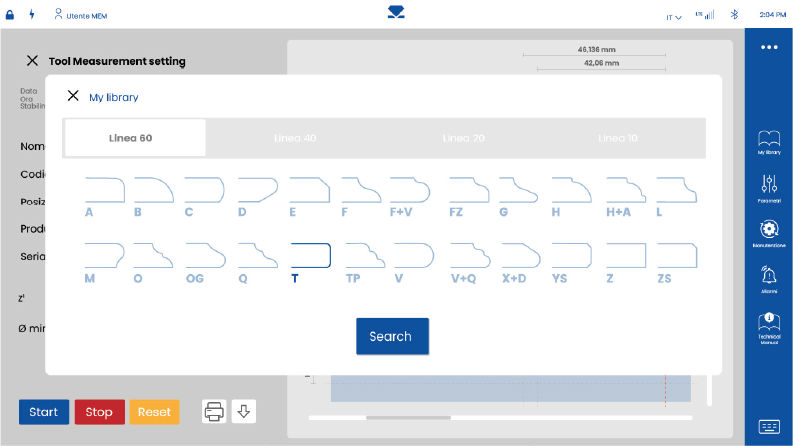

Library

In this section, you can access a complete library of pre-saved tool profiles and upload new ones, allowing for quick and organized profile management.

Wheel Scan

With a simple start, the tool is scanned, and all measurement parameters, including diameter and height, are accurately provided, ready to be set on the CNC machine.

Thanks to the option to connect a printer, you can generate a physical label containing the tool’s parameters.

Smartphone Acces

With the remote access function via smartphone, users can view tool parameters directly from their mobile device, eliminating the need to print labels and providing a practical solution for setting up tools directly on the machine.

CNC Access

The MARMO PRESETTER offers the ability to integrate directly with the onboard CNC system through a dedicated web app. This allows for the automatic transfer of data from the newly scanned tools directly to the CNC machine, without the need to manually transfer the information.

Remote Support

ON-LINE SUPPORT

Experience superior online support for our products. Our experts provide real- time assistance, tailored recommendations, and innovative solutions for precision machining, ensuring optimal performance and productivity in every operation.

ONSITE SUPPORT

Elevate your work with our onsite support for our products. Our experts bring tailored recommendations, real-time assistance, and innovative solutions to your location, ensuring optimal precision and productivity

in every operation.

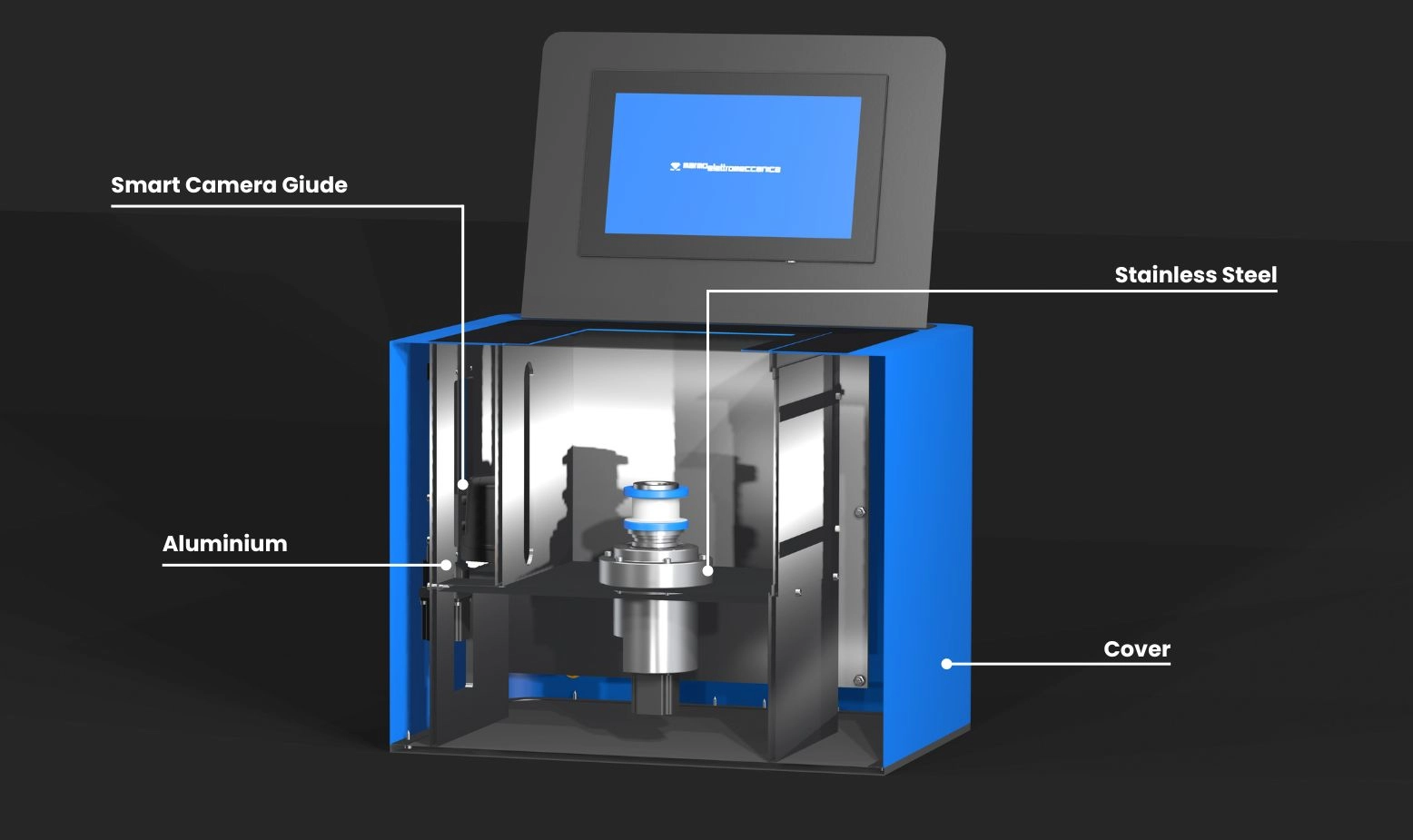

MARMO PRESETTER:

Built to Last

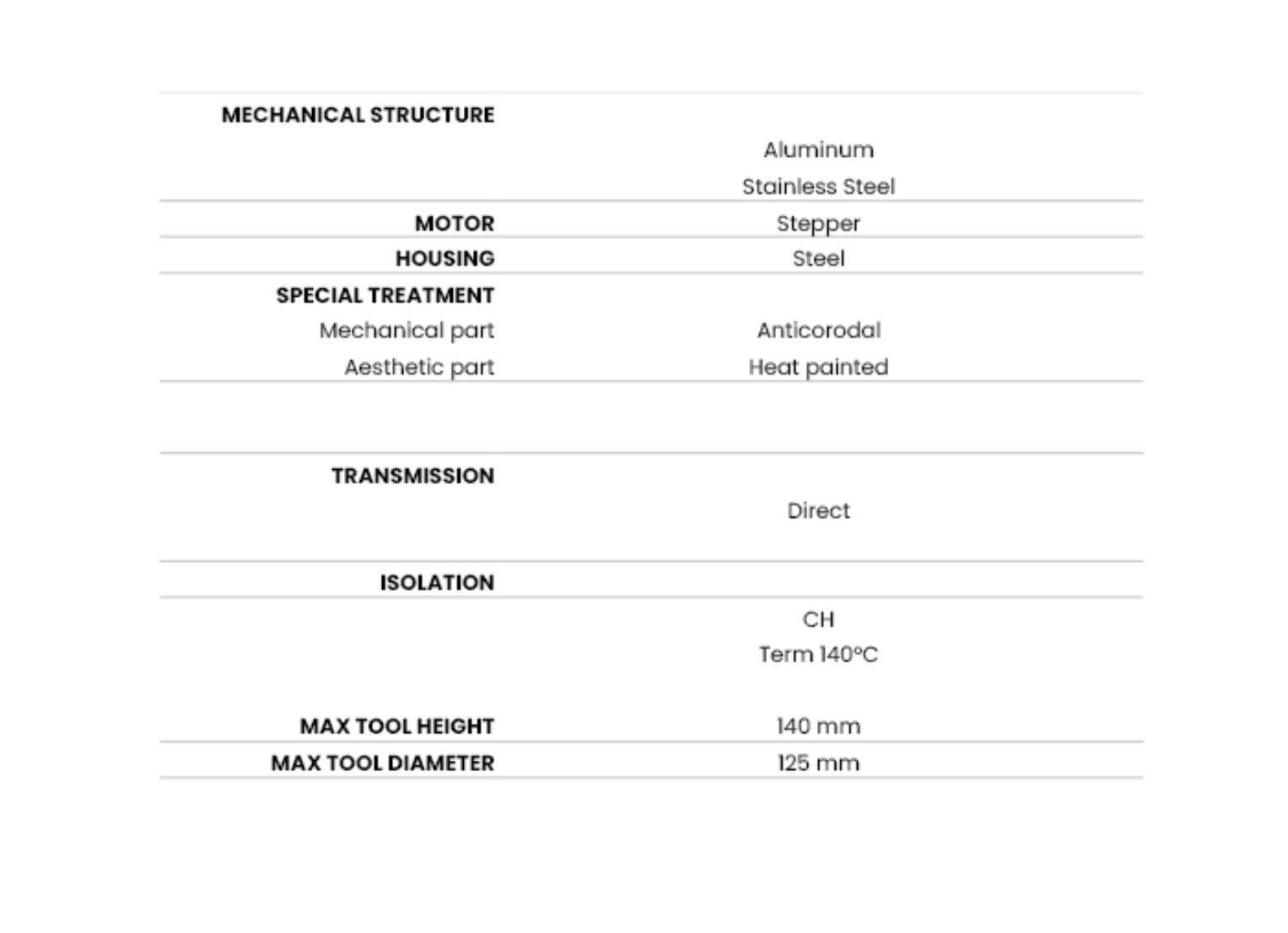

Like all Marmoelettromeccanica machines, the MARMO PRESETTER is entirely built from stainless steel and aluminum, materials chosen to ensure maximum durability and long-term resistance. This combination also offers superior resistance to corrosion, wear, and environmental stress.

These durable materials reduce the need for maintenance and replacement.

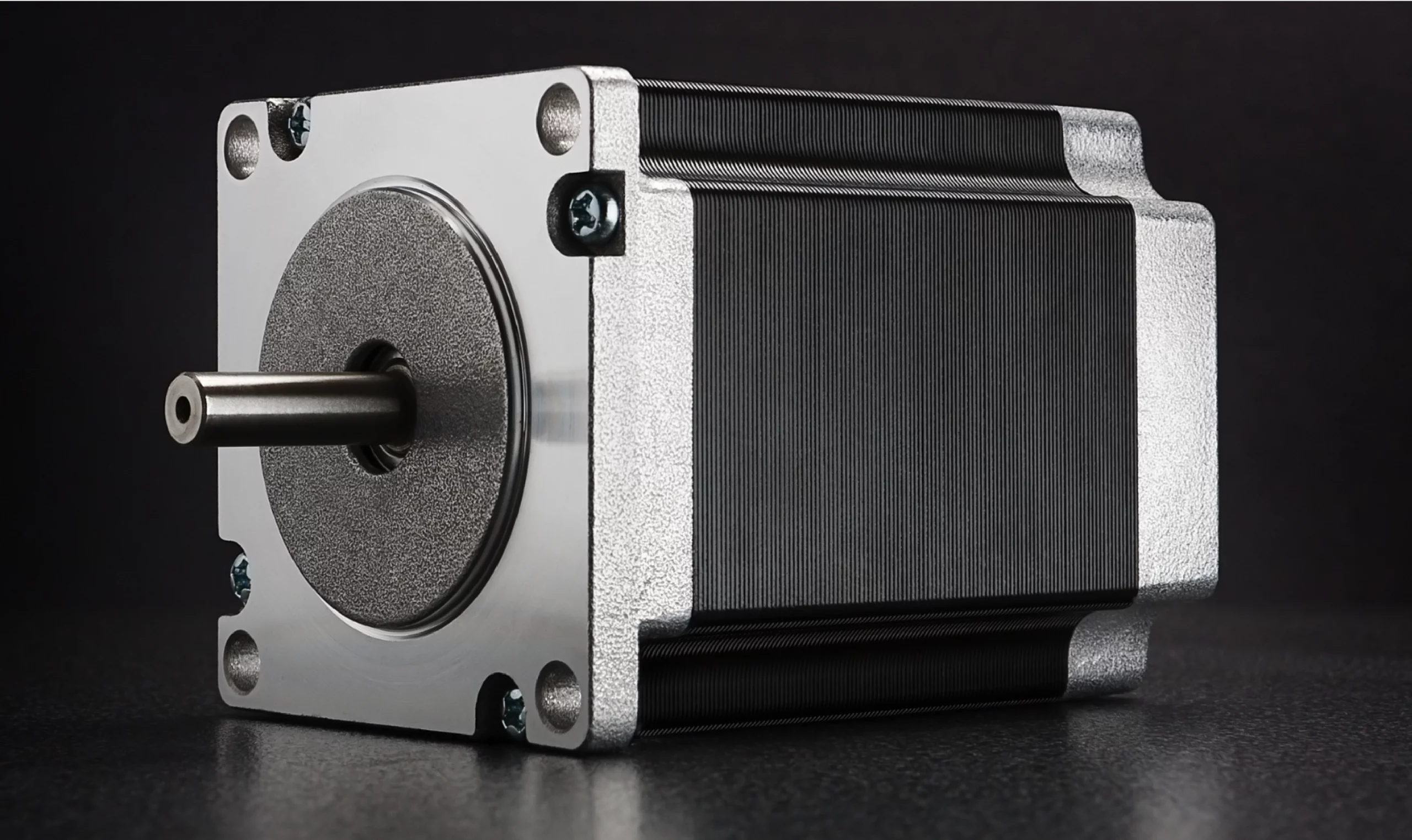

Stepper Motor:

Efficiency and Superior Performance

The MARMO PRESETTER is equipped with a 2-phase hybrid stepper motor, a technological choice that offers numerous advantages in terms of efficiency and performance.

The MARMO PRESETTER with a stepper motor, represents the pinnacle of technology in terms of mechanical and electrical efficiency, guaranteeing users superior performance and reduced operating costs, making every job simpler and more productive.

100% Made in Italy –

100% Made in Marmoelettromeccanica

Our production is proudly 100% Made in Italy and 100% Made in Marmolettomeccanica. We guarantee the entire production process internally, from structural and electrical design, to CNC programming, rubber molding, and the creation of electrical systems and software.

Even post-sales support and installation are managed internally by our specialized staff. This commitment allows us to ensure the highest quality of our products, maintaining total control over every aspect of production.

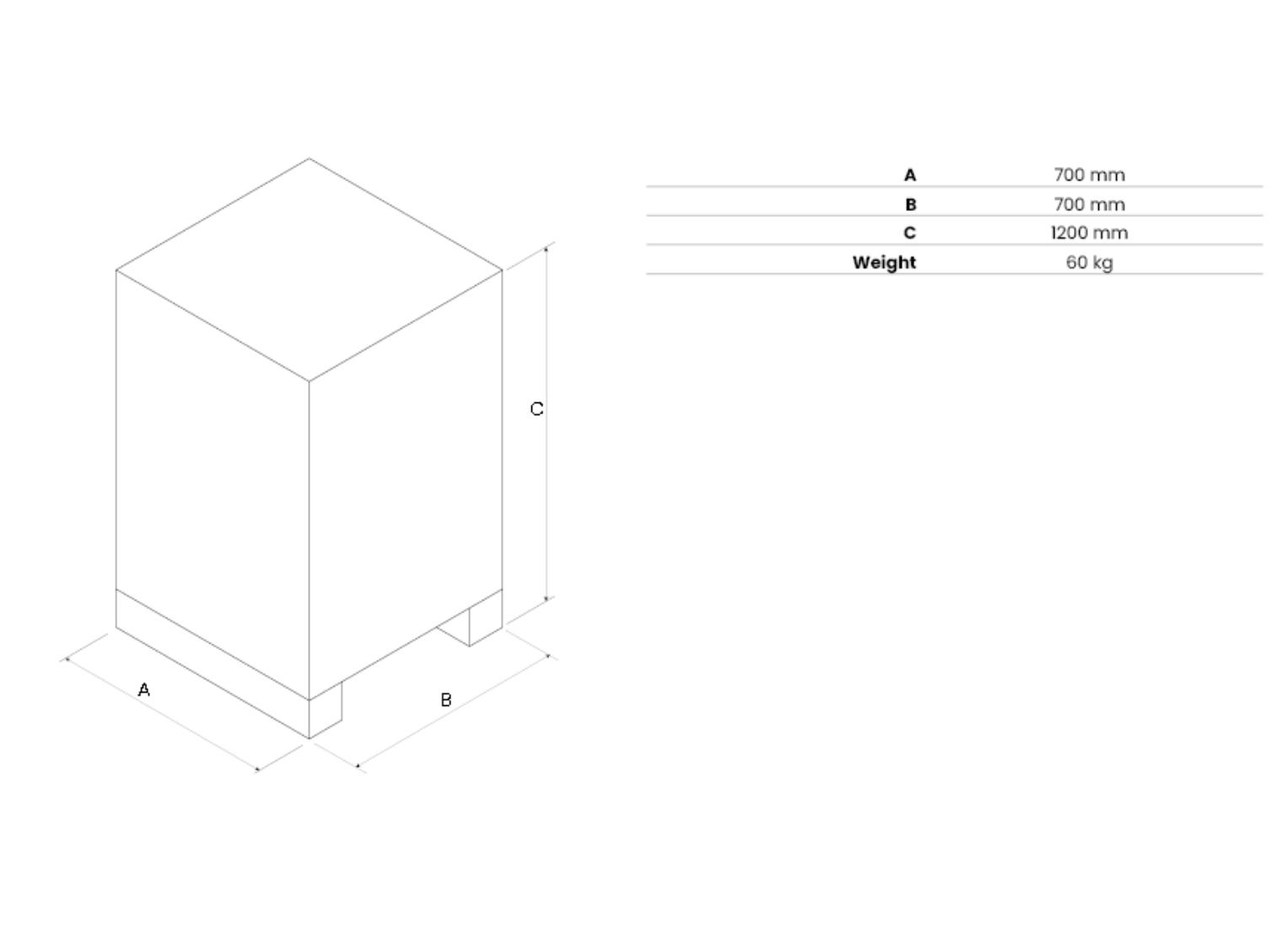

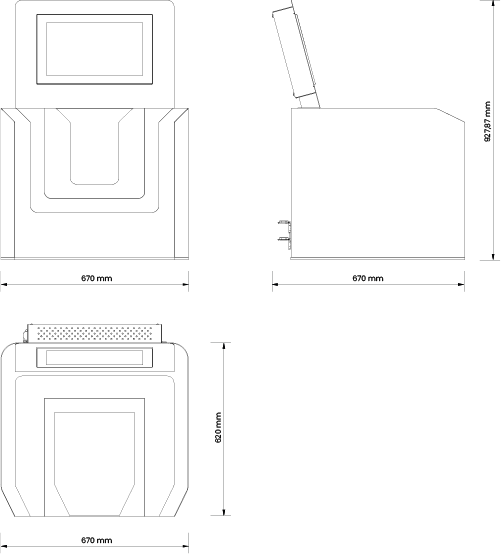

Technical Drawing

MARMO PRESETTER

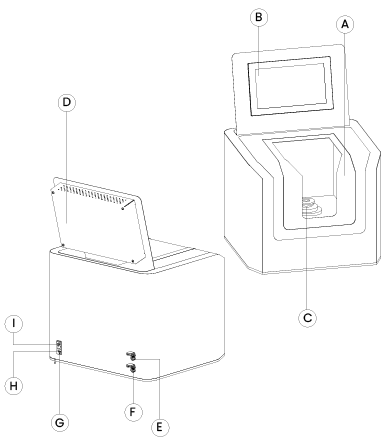

Detailed description

A- Door for access to the work area. Movable door with a transparent section that allows monitoring of ongoing operations while maintaining high safety standards.

B- 15,6’’ Control Panel. Large touchscreen display for interacting with the machine.

C – ISO 40 CONE with automatic rotation. Housing for profiles with 360° automatic rotation.

D – Electrical component for the software. Control unit for the CNC software.

E – USB access. USB port for connecting printers or external storage devices.

F – Ethernet access. Ethernet port for connecting the device to the internet.

G – Electrical power supply 110/220 V. Power cable connection.

H – On-off switch. Power button.

I – Fuse holder. Housing for fuse.

Technical Data

Packaging