Technical Support

- Video

- Installation

- Parameter

- Live Technical Support

- FAQ

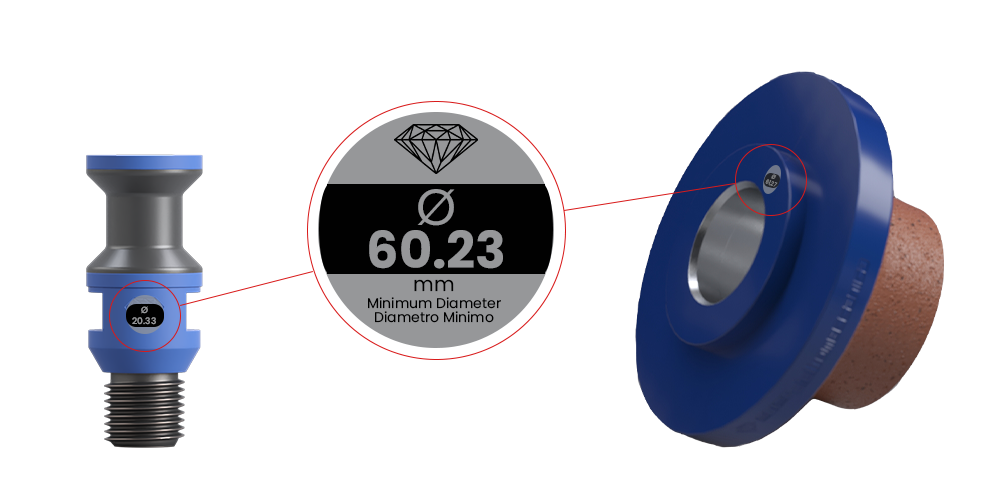

Tool Ø

Every MEM profile wheels comes with a sticker which indicates the minimum diameter of the diamonded part of the tool. Please note that the diameter is in mm. You must enter exactly the same value to the parameter calculator.

Scan QR Code

Starting from July 2020 all MEM boxes will have a QR code on them which by scaning it you will be directed to the parameter calculator page of our website. In any other case you can go to the parameter calculator section on our website.

Plug-in Measurement

Done!

Online chat

Call

Technical Visit

Video Call Support

Remote Access

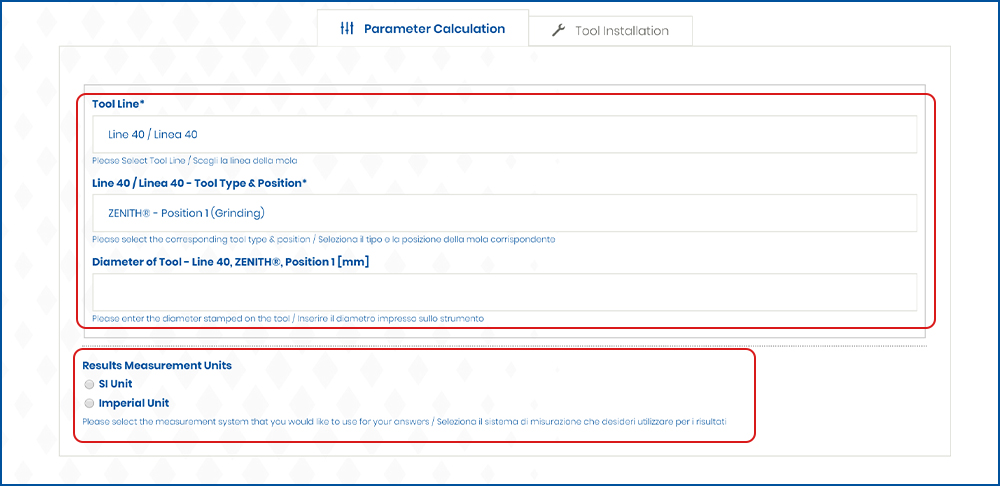

What are the working parameters?

Every MEM tool sold comes with a manual and working parameter data sheet. Nevertheless you can always use our parameter calculator online to get more accurate parameters. You can always contact us if you are having any kind of problem with the tools, our technicians will respond to you as soon as possible. You also have the option to book any of our technicians so they can visit you and help you with your work.

There are 2 things to remember when installing MEM tools:

- The Z coordination of all of the positions is same, therefore you do not need to calculate each and every position’s Z coordination.

- The polishers should be treated like a metallic tool therefore the dynamic compensation should be deactivated on your CNC.

Product warranties?

Marmoelettromeccanica has a multistage quality control system and every single tool is checked individually. If you are not satisfied with our product, please contact us as soon as possible so we can check the tool problem for you or to replace it with a new product.

Polishing tools getting used too soon?

Marmoelettromeccanica’s LongLife polishing tools were the first rubber polishing tools in the world. The tools have a high life span and in the same time the highest gloss achieved by polishing profile wheels. One of the most common mostakes is not paying attention to the 3rd grinding position, since if the tool does not work properly it would leave a stock removal process for the rubber tools which might cause early failure of the polishing tools, since they are desined to increase the gloss.