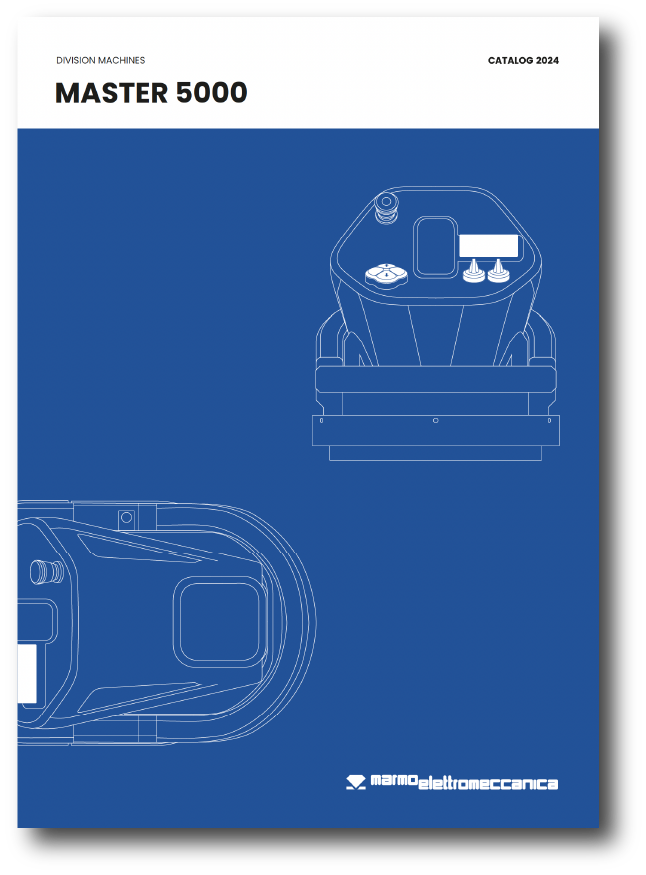

Master 5000

Master 5000

With over thirty years of excellence in the field of stone processing machines, we are proud to introduce the Master5000, a revolutionary contouring machine that represents the pinnacle of our technological evolution. Designed to precisely contour, drill, and polish marble, granite, and other stone materials, the Master5000 blends the solidity of traditional methods with the latest technological innovations. This historic model, which has shaped the landscape of stone processing, has been completely revamped to meet the demands of the most exacting professionals and to ensure unmatched performance.The Master5000 is not just a machine, but a legacy of quality and reliability, designed to transform your business and propel the art of stone processing into the future.

Why process with Master 5000?

You don’t need a stationary CNC machine: our Master 5000 replaces numerous needs in terms of both space and time. The new manual CNC can cut and polish internal and external surfaces and profiles. It can shape complex contours very precisely and on materials of any kind.

Profiling

Drilling

Sink Hole

Slab Polisher

New intelligent functions

![]()

Motorized Z-Axis

The motorized movement of the Z-axis simplifies and speeds up the adjustment of the grinding wheel’s height. This feature enhances the usability and efficiency of the Master 5000.

![]()

Parameters Display

the Z-axis positioning is displayed on the screen, providing real-time feedback and high precision.

![]()

Speed Controllers for Z-Axis and

Rotation Speed

The Master5000 elevates the art of stone processing with its innovative control features. Equipped with two intuitive selectors, this contouring machine allows for the adjustment of both the Z-axis speed and the tool rotation speed. This flexibility ensures that every type of processing, from the simplest to the most complex, is performed with utmost precision and adaptability.

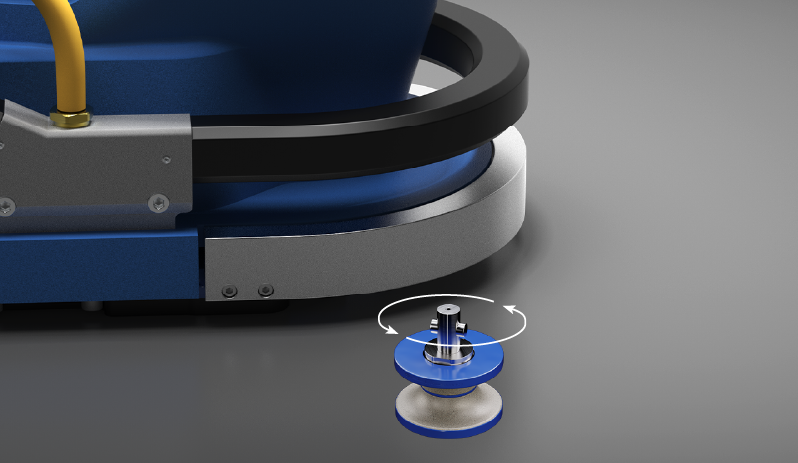

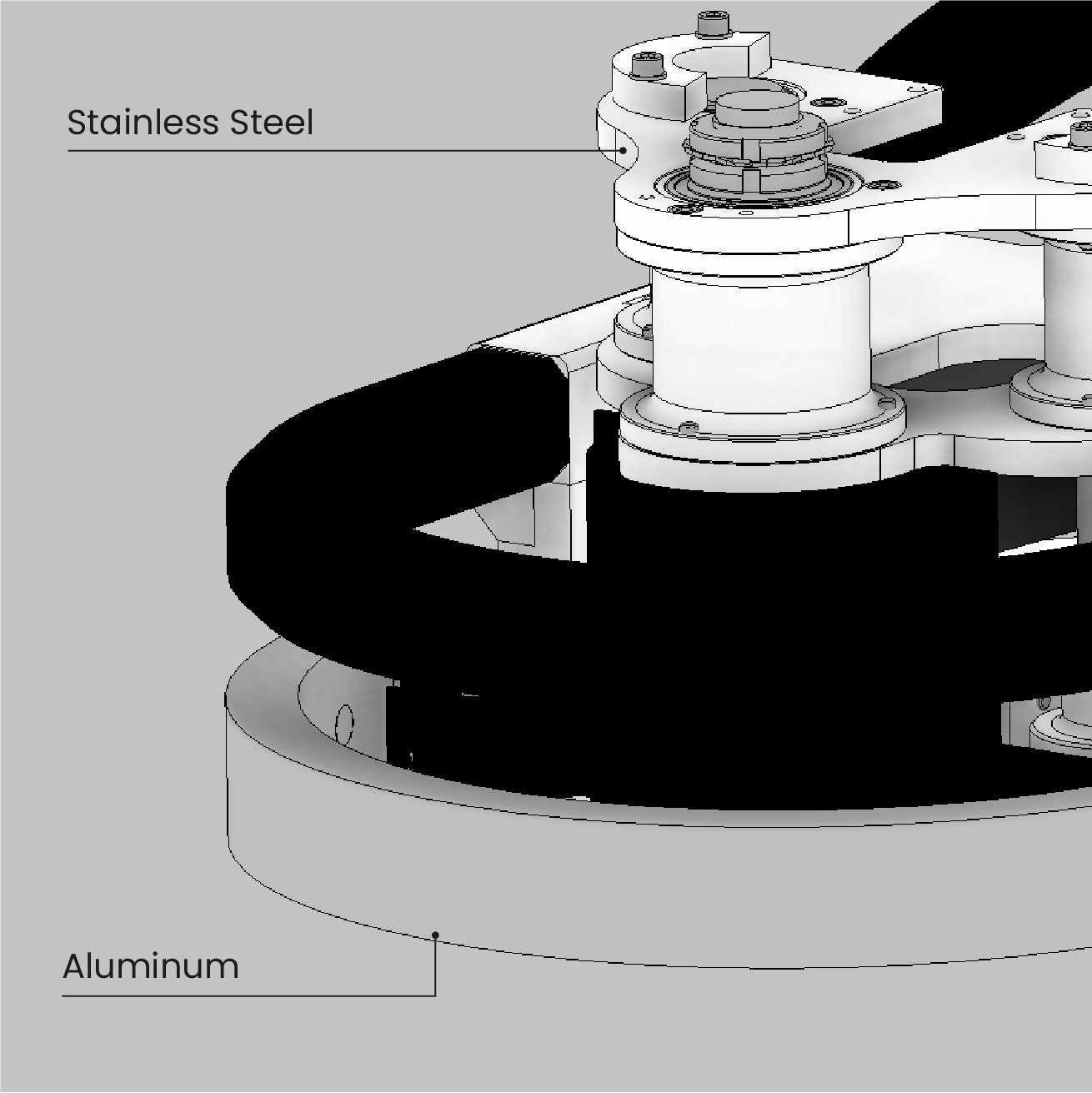

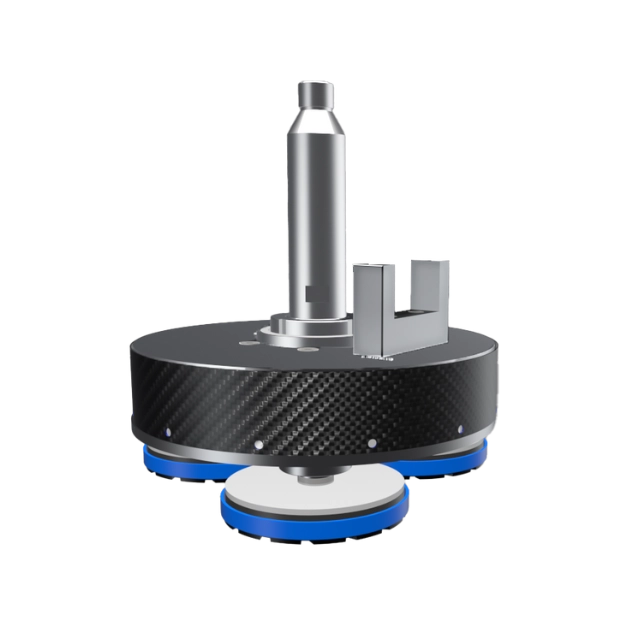

Quick-Connect Tool

The quick-release grinding cone is ideal for those seeking efficiency and speed. This component is designed to facilitate a quick and safe replacement of the grinding wheel, optimizing work times and increasing productivity in the workshop.

Quick Release

Thanks to the quick-release attachment system, the grinding wheel can be changed in just a few seconds. This feature is essential for minimizing interruptions during tool changes.

Stainless Steel

The attachment is made from stainless steel, known for its exceptional resistance to corrosion and rust. The use of this material ensures greater durability and maintains the structural integrity of the grinding cone over time.

Robust Design

The design of the cone has been developed to ensure maximum stability and safety during use. The stainless steel contributes to the robustness of the cone, ensuring that it remains reliable under stres

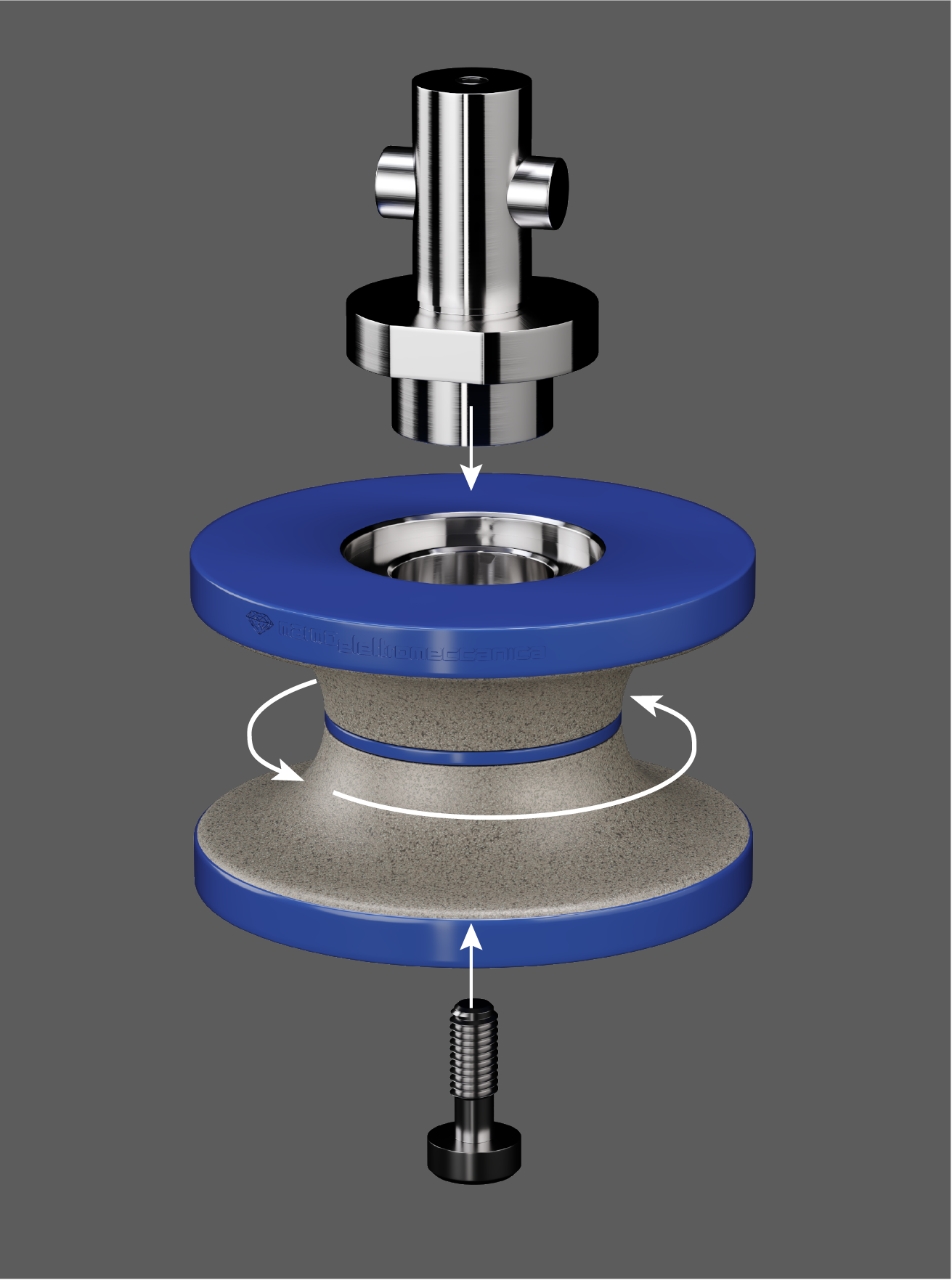

Water System Plate

The Water System Plate is designed to enhance performance by allowing it to glide over a thin film of water. This unique feature ensures exceptionally smooth operation, preventing scratches on the surfaces of the materials being processed.

Smooth Operation

The water film between the machine and the material ensures that the Master 5000 moves effortlessly, reducing friction and preventing scratches on delicate surfaces.

Unique Design

Developed by Marmoelettromeccanica, this system is considered the best on the market. Its design not only improves operational fluidity but also contributes to the overall efficiency of the Master 5000.

Reliability and Durability

The Water System Plate is built to last. It does not clog or stop, ensuring continuous operation and long-lasting performance.

Speed Controllers for Z-Axis and Rotation Speed

The motorized movement of the Z-axis simplifies and speeds up the adjustment of the grinding wheel’s height. This feature enhances the usability and efficiency of the Master 5000. Additionally, the Z-axis positioning is displayed on the screen, providing real-time feedback and high precision. This allows the operator to easily set a specific measurement, simply moving to the desired position for the execution of the task. This integrated system ensures accurate and efficient processing, reducing setup times and increasing productivity.

The speed controllers for the Z-axis and rotation speed are crucial components for maximizing flexibility and efficiency in processing various materials. The Z-axis speed controller allows for precise control during delicate operations such as drilling, adapting to the specific needs of each material and process. This ensures optimal results without compromising quality. Similarly, the rotation speed controller is essential for setting the optimal speeds for each type of tool, whether it’s a drill bit, a cutting mill, diamond grinding wheels, or polishing wheels. This flexibility in settings not only ensures maximum cutting and polishing effectiveness but also protects the tools from premature wear, significantly extending their useful life.

Increased Precision

The ability to finely adjust the Z-axis and rotation speeds ensures maximum precision in processing.

Versatility

With speed adjustment, operators can easily switch between different types of processing and materials, increasing the versatility of the Master 5000.

Tool Durability

Setting the appropriate speed for each tool prolongs the life of the tools themselves.

Safety and Efficiency

at Low Voltage

The Master 5000 is designed to ensure maximum safety in any work environment, operating at a low voltage of 48 volts. This makes it particularly safe for operators working in the presence of water. The low voltage also ensures the power and effectiveness of the machine, delivering high performance in all conditions of use.

The Master 5000 combines advanced technology with uncompromised safety, setting new standards in the industry for operator protection and operational effectiveness.

![]()

Smooth Operation

Operating at only 48 volts, the Master 5000 provides a safe working solution even in damp environments. This aspect is crucial for preventing injuries and ensuring workplace safety. been developed to ensure maximum stability and safety during use. The stainless steel contributes to the robustness of the cone, ensuring that it remains reliable under stress.

![]()

Unique Design

Its compatibility with wet environments makes it the ideal choice for sectors such as marble processing and other applications that require the presence of water during the process.

![]()

Reliability and Durability

Thanks to its low voltage configuration and other integrated safety measures, the Master 5000 is considered the safest machine in the world in its category, offering complete peace of mind to operators.

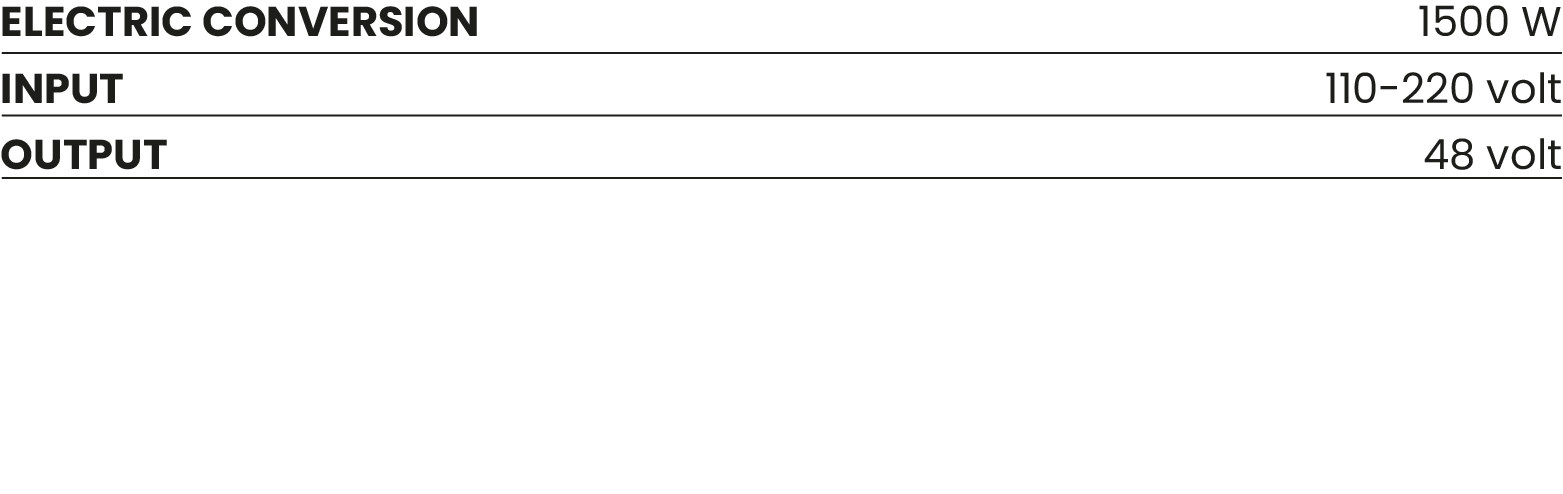

High Versatility and Power Machine

This machine is designed to operate at voltages of 110 volts or 220 volts, making it suitable for use in any workshop or construction site. This versatility in power supply ensures that the machine can be easily integrated into various work environments without the need for special adapters or transformers. The Master 5000 combines excellent power and operational flexibility, setting new standards of versatility and reliability in its field, and ensuring high-performance levels in every usage condition.

![]()

Dual Voltage Option

With the ability to function at both 110 volts and 220 volts, the machine offers unprecedented flexibility, easily adapting to both small artisan workshops and large industrial sites.

![]()

Guaranteed Power

A consumption of 1500W for 220 volts and 14Ah for 110 volts ensures that the machine has the necessary power for heavy and continuous operations, maintaining high standards of efficiency and productivity.

![]()

Ideal for Any Environment

Its ability to operate with different voltages makes it ideal for international use, overcoming barriers that often limit the use of heavy machinery due to local power specifications.

Master 5000:

Built to Last

This machine is designed to operate at voltages of 110 volts or 220 volts, making it suitable for use in any workshop or construction site. This versatility in power supply ensures that the machine can be easily integrated into various work environments without the need for special adapters or transformers. The Master 5000 combines excellent power and operational flexibility, setting new standards of versatility and reliability in its field, and ensuring high-performance levels in every usage condition.

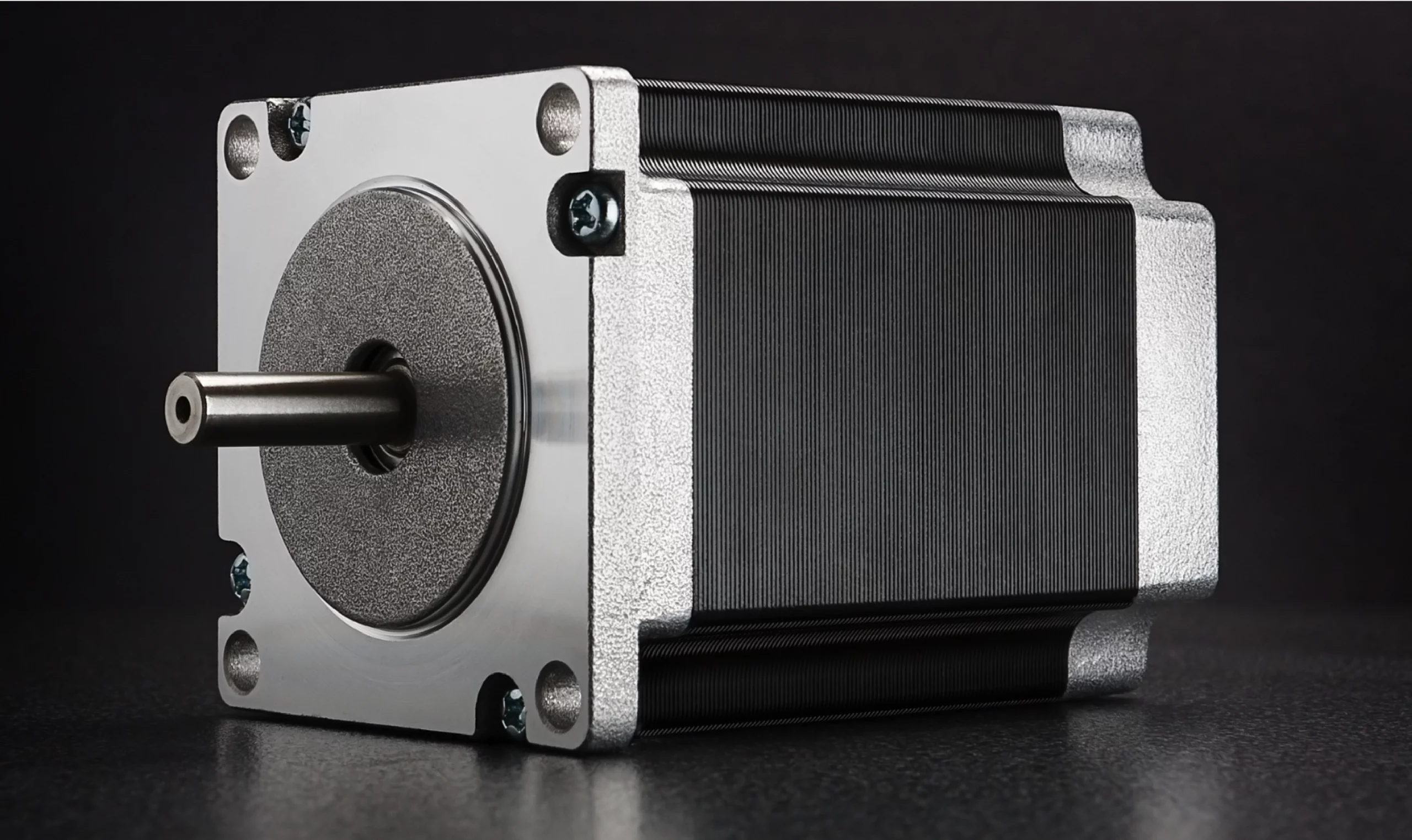

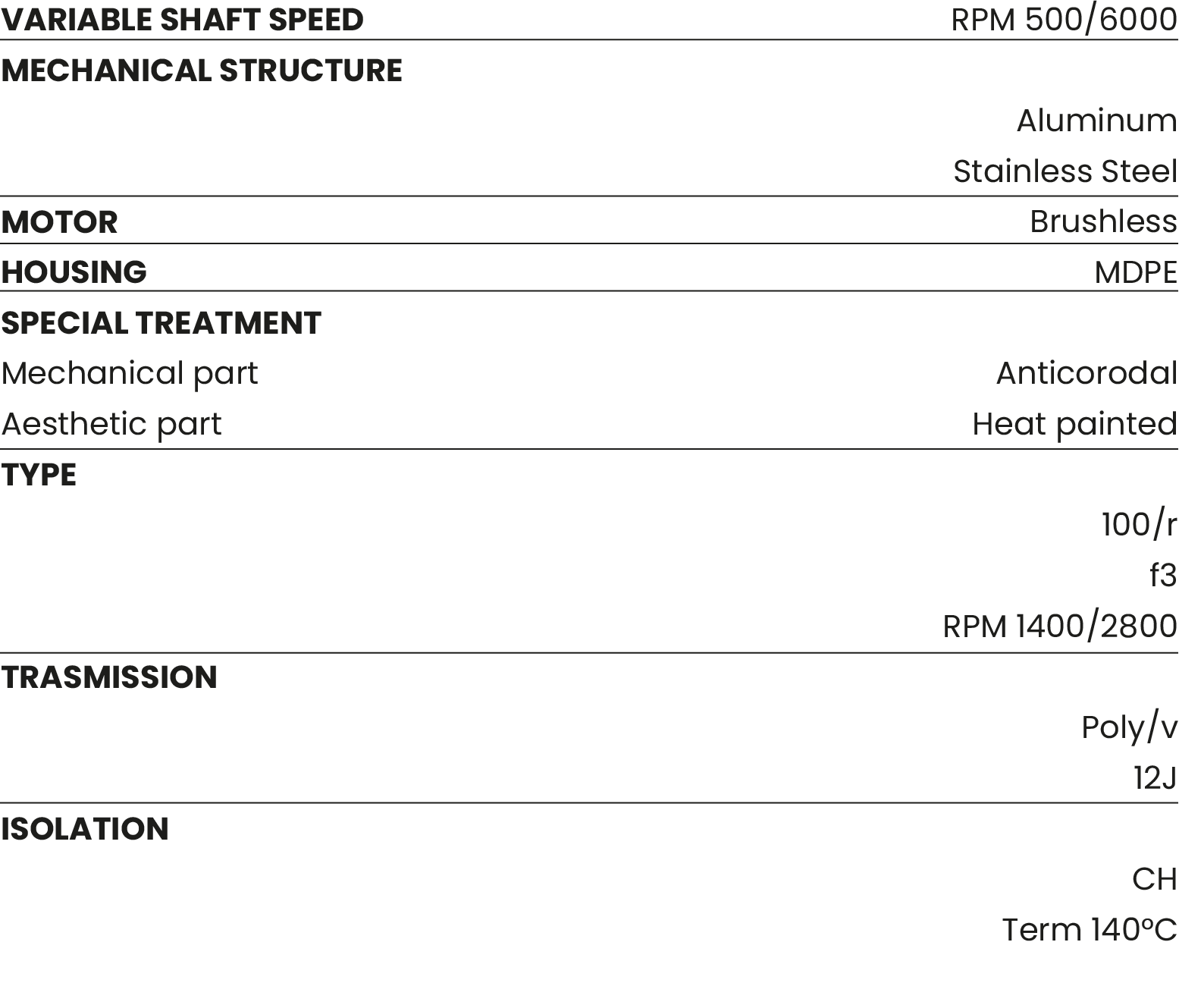

Brushless Motor:

Efficiency and Superior Performance

This machine is designed to operate at voltages of 110 volts or 220 volts, making it suitable for use in any workshop or construction site. This versatility in power supply ensures that the machine can be easily integrated into various work environments without the need for special adapters or transformers. The Master 5000 combines excellent power and operational flexibility, setting new standards of versatility and reliability in its field, and ensuring high-performance levels in every usage condition.

![]()

Energy Efficiency

Brushless motors are known for their high energy efficiency. They consume less power and produce more output per watt compared to traditional brushed motors, reducing operational costs and environmental impact.

![]()

Increased Durability

With no brushes, the brushless motor has fewer parts that wear out, significantly extending the motor’s lifespan. This translates into less maintenance and fewer replacements needed.

![]()

Enhanced Performance

The brushless motor ensures constant power output at both low and high speeds, thus ensuring maximum performance.

![]()

Reliability

With fewer mechanical components subject to wear, brushless motors offer greater reliability and consistent performance, even under heavy loads and in challenging operational conditions.

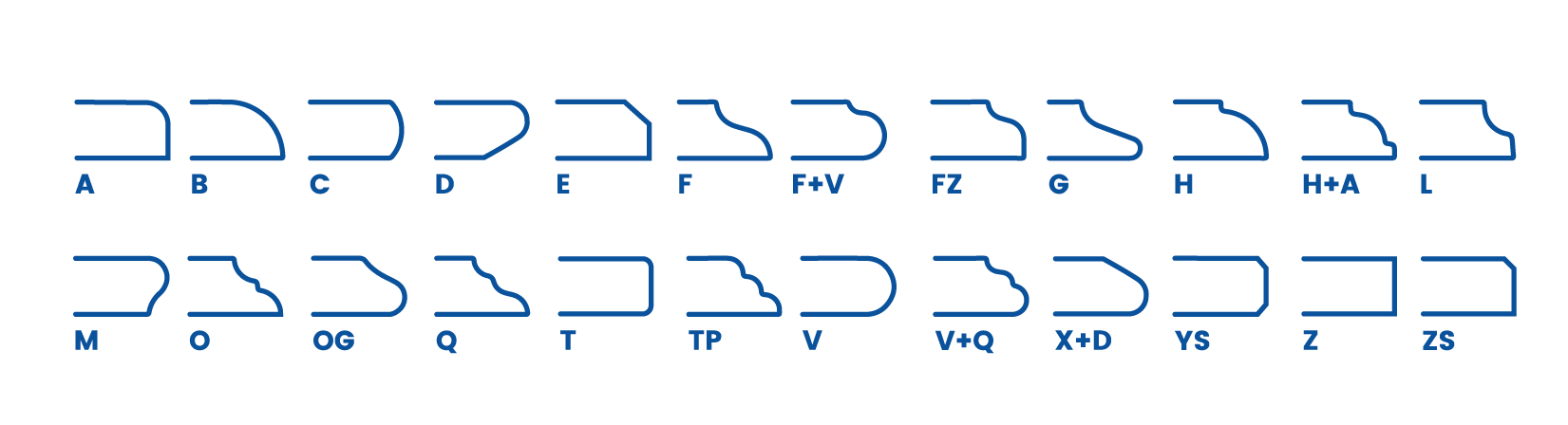

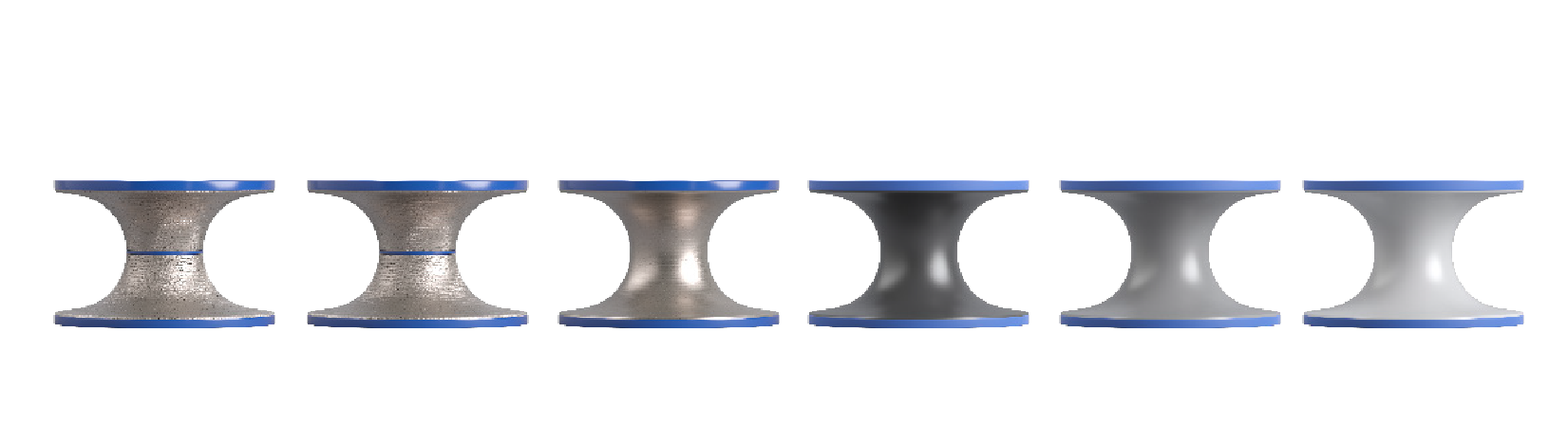

Internal and external profiling

For every edge in granite, quartz, ceramic, marble, and other materials, our technology allows for a transition from rapid contouring to impeccable polishing. With over 200 standard profiles available in stock, the possibilities for customization are endless.Furthermore, we create profiles based on specific customer requests, ensuring tailor-made solutions for every need.

STEP 1 – Profiling

STEP 2 – Polishing

Sink Hole

Drilling and Cutting with the Master 5000

The Master 5000 enables the use of drill bits for drilling and end mills for precise cutting. To fully exploit these features, the sink device is necessary, an indispensable accessory that expands the machine’s operational capabilities, making it even more versatile and suitable for meeting every specific processing requirement.

Designed for Kitchen Countertop Fabrication

The Master 5000 is engineered to meet the needs of those working with kitchen countertops, offering the capability to install 20 mm grinding wheels with a half-gas attachment. This allows for the creation of internal holes up to a radius of 10mm, from roughing to perfect polishing.

STEP 1 – Hole

STEP 2 – Cut

STEP 3 – Profiling

STEP 4 – Polishing

Polishing Slabs

The Master5000 stands out for its ability to completely transform the slabs in your warehouse, precisely meeting the specific requirements of each customer. Thanks to the use of the Master Polishing Slabs Device, this machine allows for polishing, smoothing, and brushing a wide range of materials such as marble, granite, travertine, and limestone with ease and speed. The versatility of the accessory enables operators to quickly adapt to different finishing needs, significantly increasing the efficiency of the workshop. With its advanced features, the Master5000 is the ideal solution for workshops looking to elevate the quality and variety of their work, ensuring exceptional results and customer satisfaction in every project. For this process, the use of the Marmo Smart Station is required.

STEP 1 – Metal Diamond Plate

STEP 2 – Polishing Diamond Plate

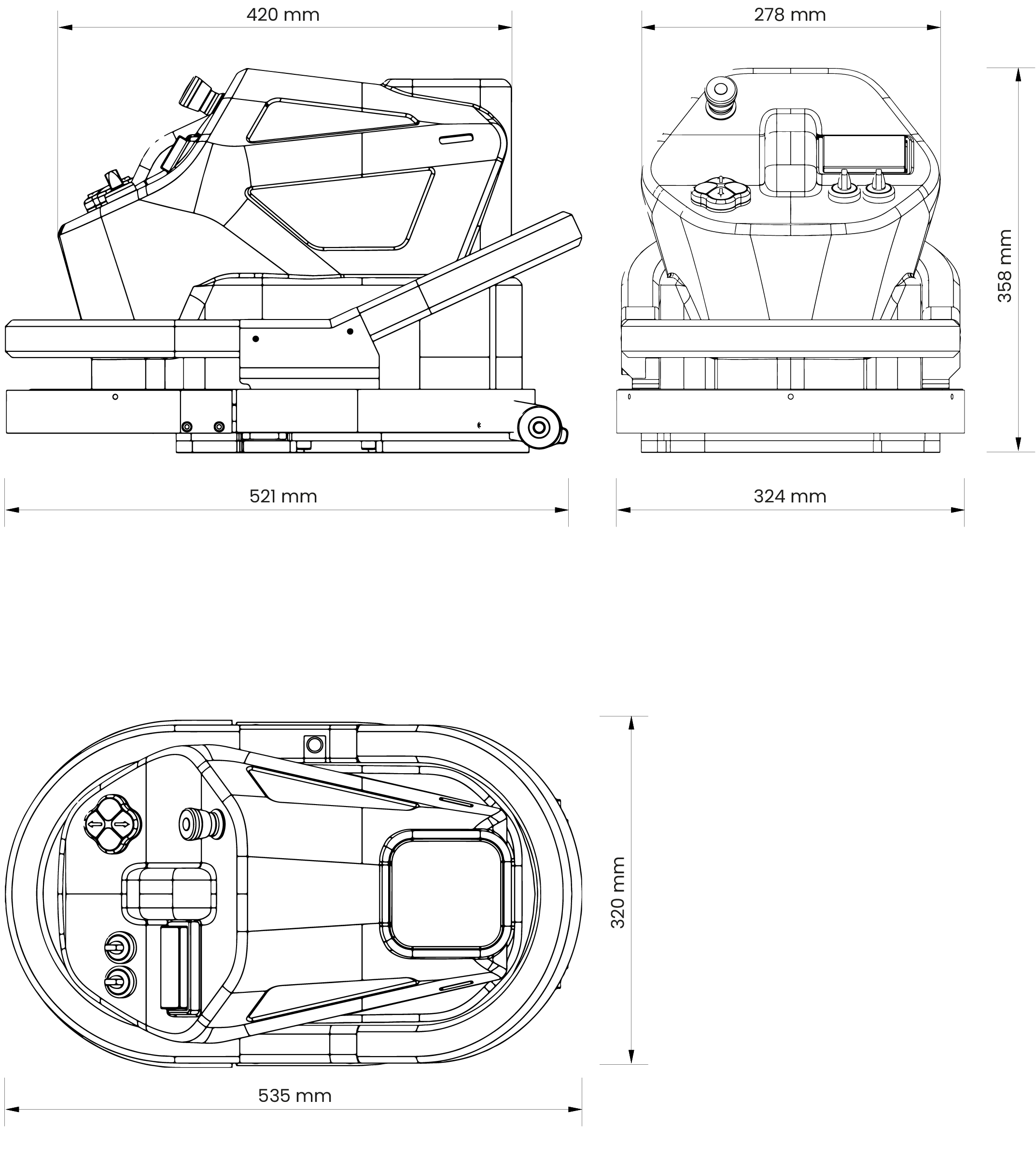

Technical Drawing

Master 5000

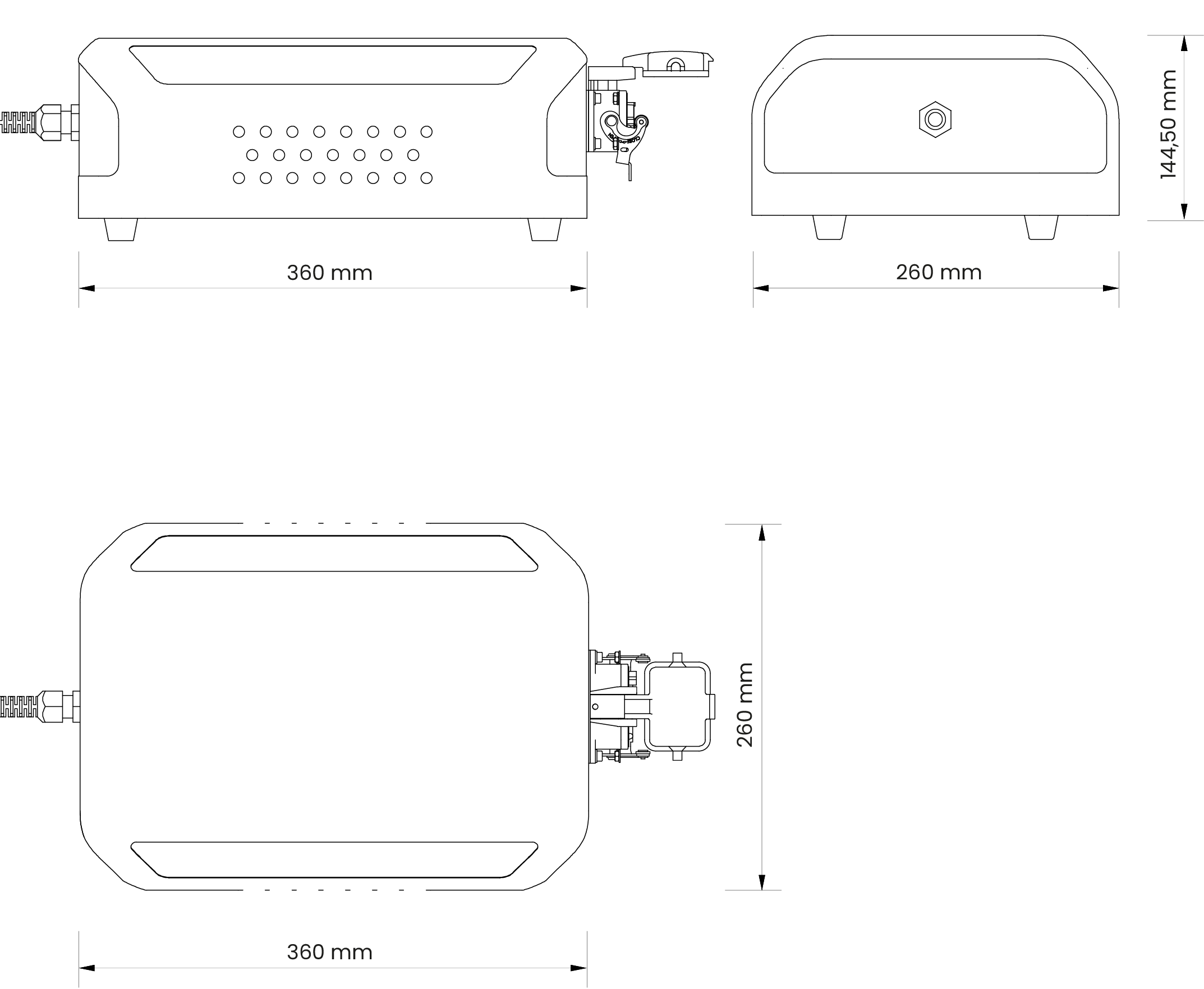

Electrical conversion unit

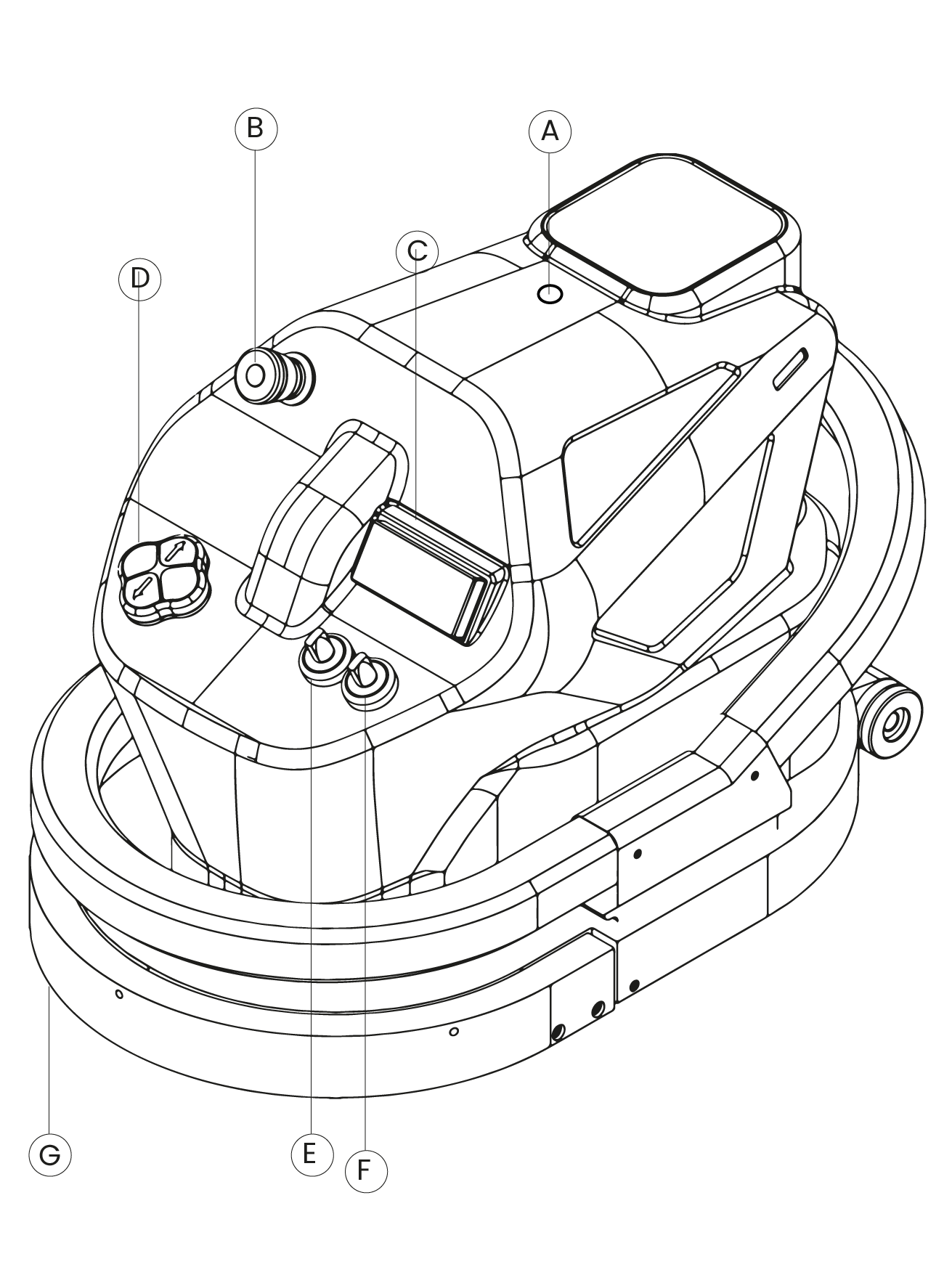

Detailed description

A- Electrical cable. the 48 volt current has to travel 6 metres long; the cable must always be connected to the central conversion unit by a special plug.

B- Stop button. Red stop switch is marked with “OFF” gives you the possibility to quickly turn off the machine even in an emergency.

C – Monitoring display. The positioning of the Z-axis is shown on the screen, providing real-time feedback and high precision.

D – Adjustment buttons. The height of the Z-axis is controlled and adjusted through the dedicated buttons.

E- Speed Regulator. The dedicated knob allows for complete control of the grinding wheel speed.

F- Spindle Descent Speed Regulator. The dedicated knob allows for precise control of the Z-axis adjustment.

G- Water spray system. The machine is equipped with 4 adjustable water jets and a system for washing the surface which ensures that the bits cool down and that dust does not build up.

Master 5000

Electrical conversion unit