MARMO SHARPENER

MARMO SHARPENER

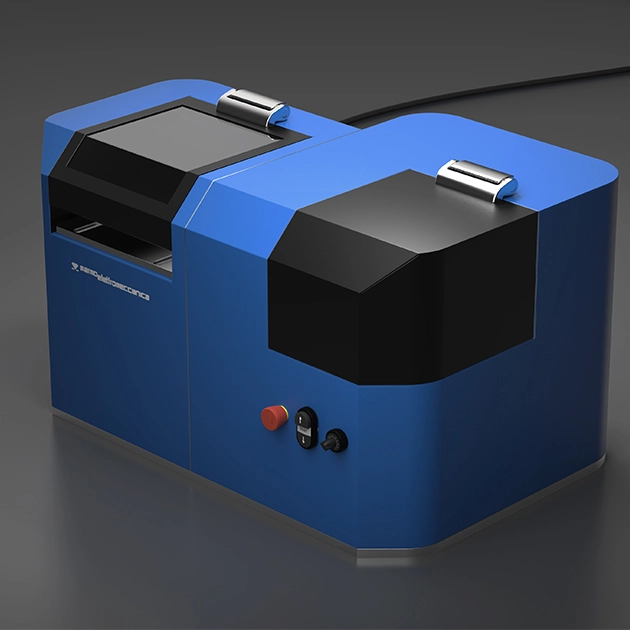

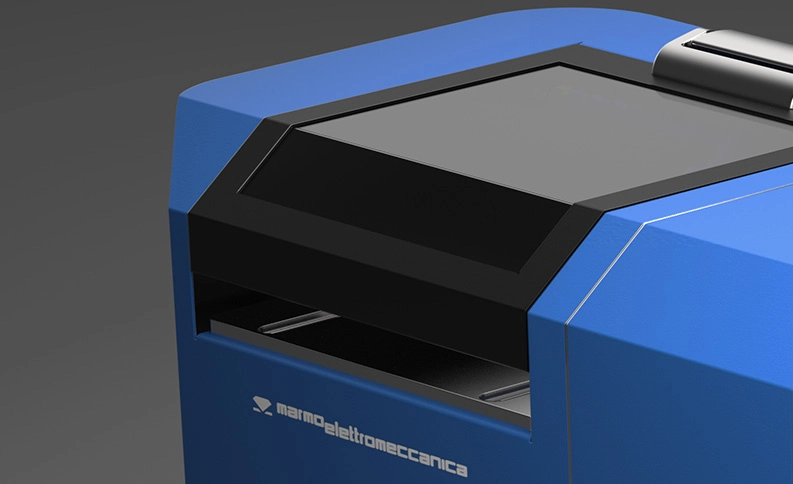

The MARMO SHARPENER is the ideal solution for stoneworking professionals, offering advanced technology for for tool redressing and sharpening.

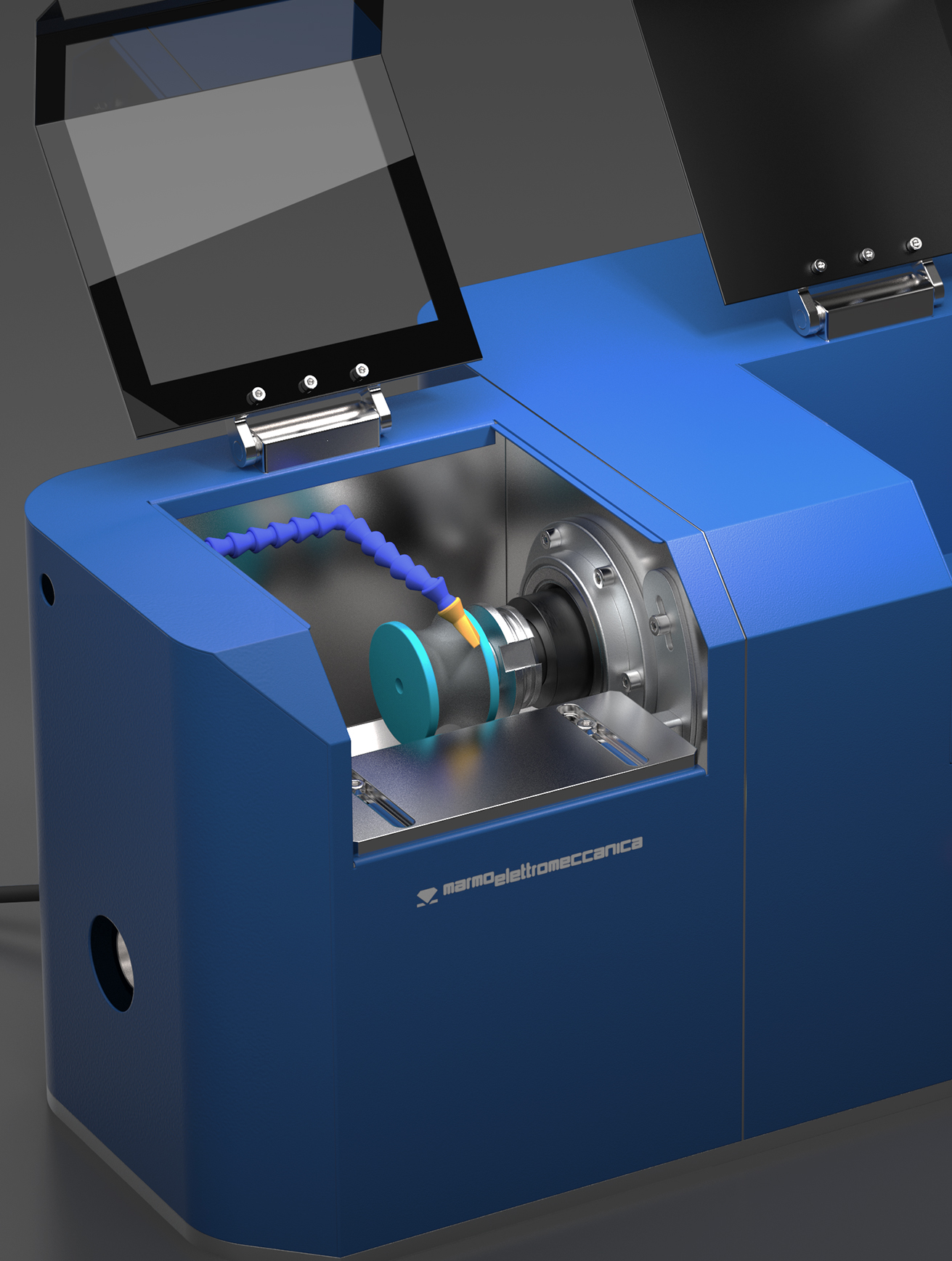

Entirely designed and manufactured in Italy with a patented design by Marmoelettromeccanica, this machine represents the excellence of Made in Italy. With the ability to enhance any profile, even the most complex geometries, this device ensures efficiency and long tool life thanks to its water cooling system that prevents clogging. Equipped with an ISO 40 cone holder, the Redresser allows for quick tool changes, increasing productivity and reducing downtime.

Safety is paramount, with hinges that stop the machine when the covers are opened and an emergency lock button. Invest in the MARMO SHARPENER for precise, safe, and efficient tool redressing and sharpening.

Extend your tool’s lifespan

The MARMO SHARPENER is the ideal device for tool redressing and sharpening, designed to prolong the life of your tools. Invest in this machine to maximize productivity and extend the lifespan of your tools.

Features

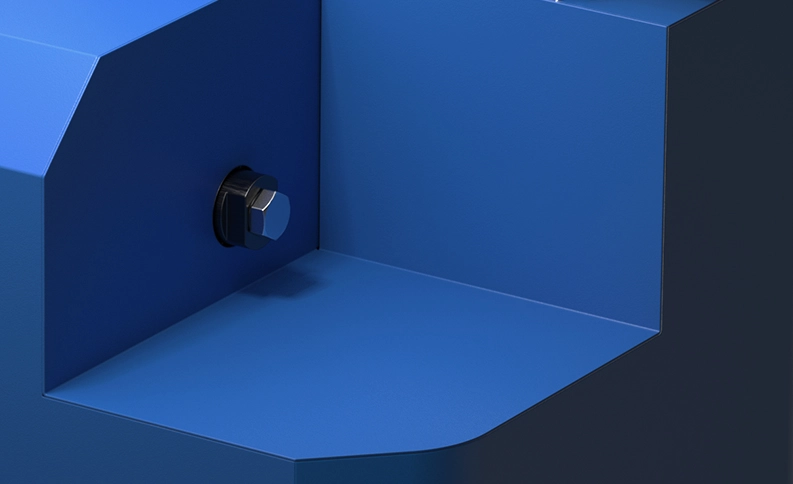

Abrasive slot

Provides secure and stable housing for the abrasive during use. Its ergonomic placement allows quick access and replacement, reducing downtime. The slot’s design ensures a firm hold, preventing movement and ensuring optimal, uniform processing results.

![]()

Start-Stop

The power button is highly visible and easy to use, featuring a specially designed ergonomic layout that allows the operator to start and stop the machine’s operational cycle effortlessly.

![]()

Safety

Workshop safety is paramount, and this Device is designed for operator peace of mind. The backlit “Off” button ensures optimal visibility in any situation, allowing operators to easily see if the machine is running and act quickly in an emergency.

![]()

Rotation Speed Controllers

The MARMO SHARPENER enhances stone processing with its innovative controls. An intuitive selector allows for tool rotation speed adjustment, ensuring precise and adaptable processing for both simple and complex tasks.

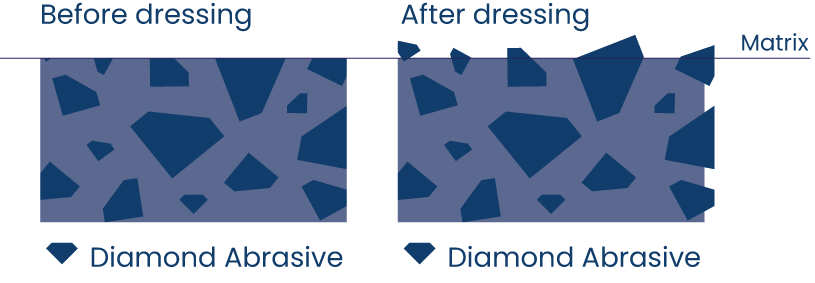

Enhance diamond technology

With the Marmoelettromeccanica MARMO SHARPENER, you can ensure that costs remain as low as possible while maintaining high efficiency standards for your tools.

Increase the productivity

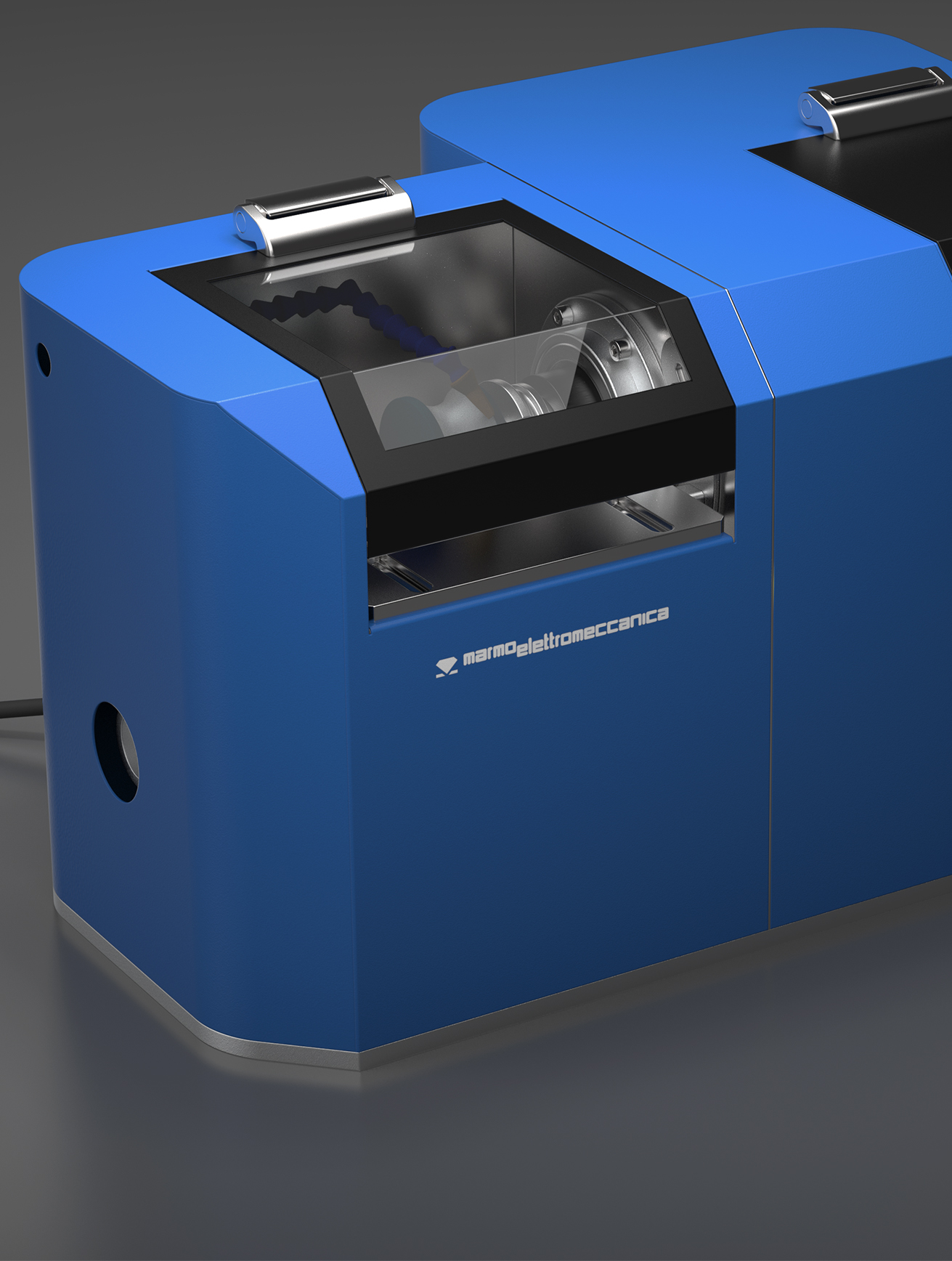

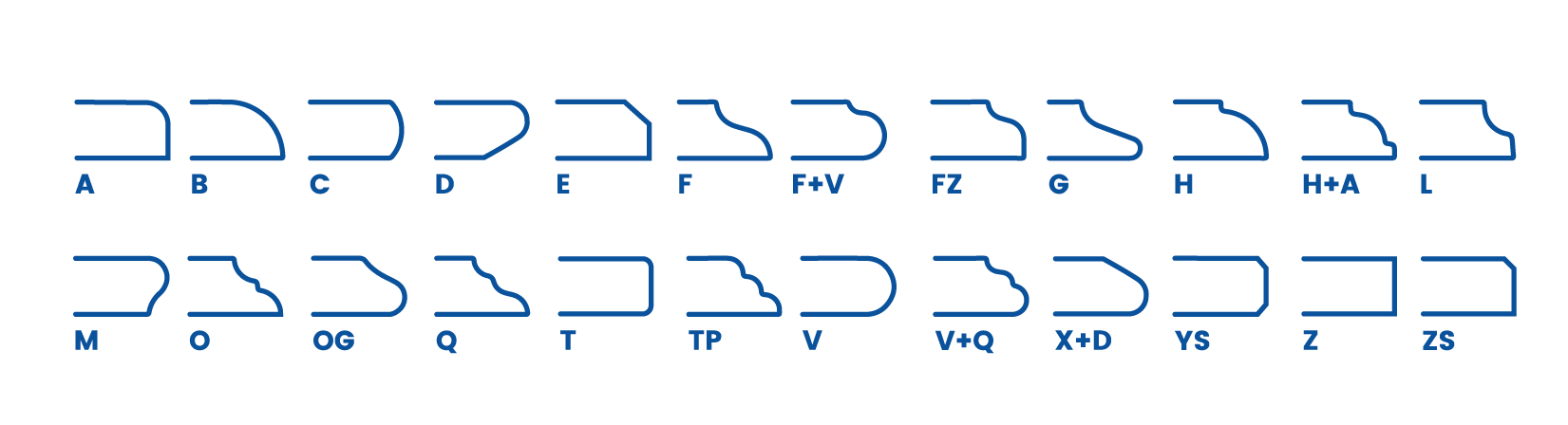

of any geometry

Achieve improvement on any profile, even on the most complex geometries. The MARMO SHARPENER is equipped with a water system that allows the machine to operate without clogging and without compromising the tool. This ensures continuous operation and long-lasting performance.

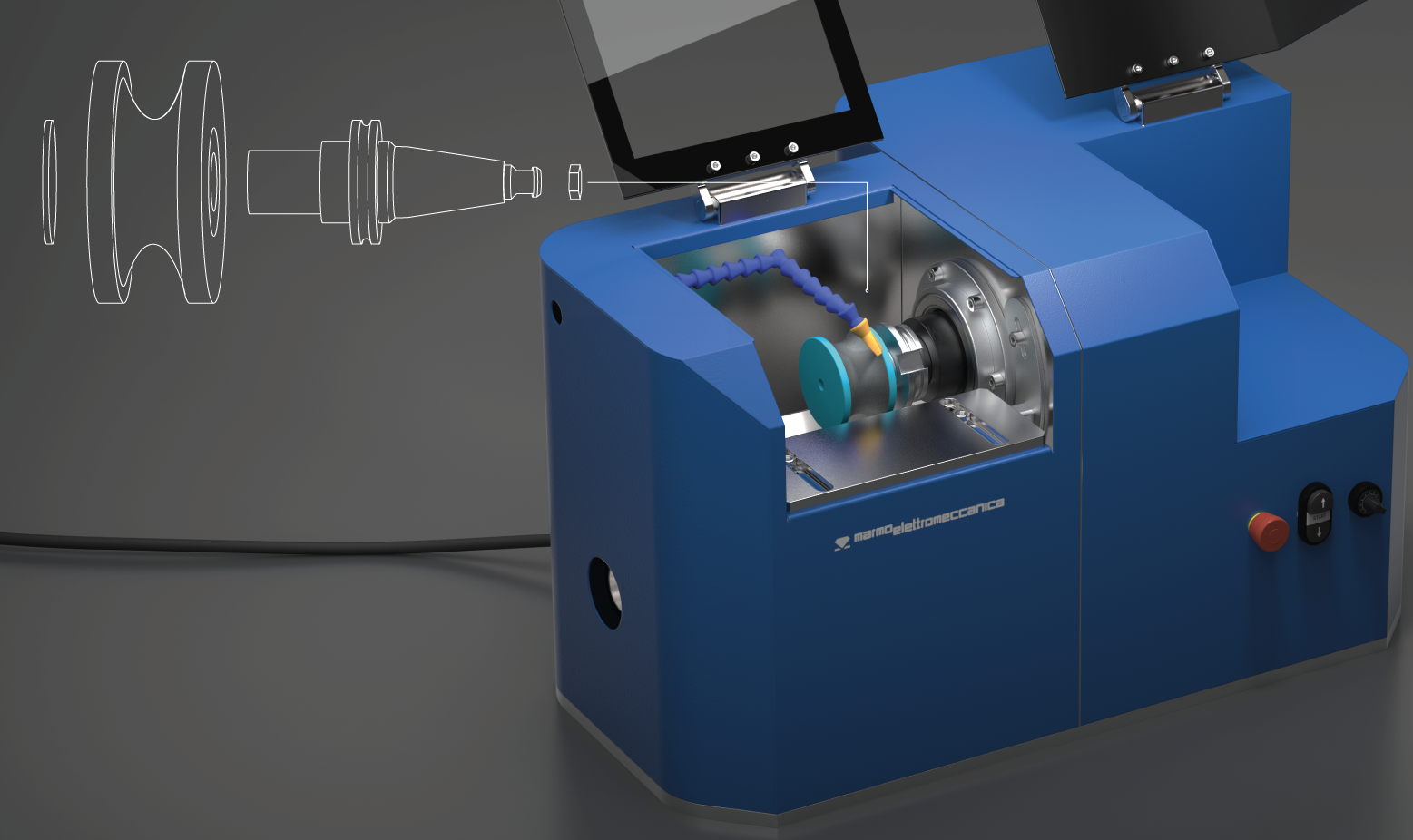

Cone ISO 40

The MARMO SHARPENER is designed with a state-of-the-art ISO 40 cone holder, ensuring precision and ease of use. To operate, simply fix the tool into the cone and insert it into the dedicated spindle holder. This feature is engineered to allow for rapid tool changes, significantly enhancing productivity and reducing downtime.

A robust clamping bolt is integral to this system, securing the cone firmly to the shaft. This ensures a safe and stable connection, providing the reliability and accuracy needed for optimal machine performance. The combination of the ISO 40 cone holder and the clamping bolt guarantees a seamless and efficient operation, tailored for demanding industrial applications.

Features

![]()

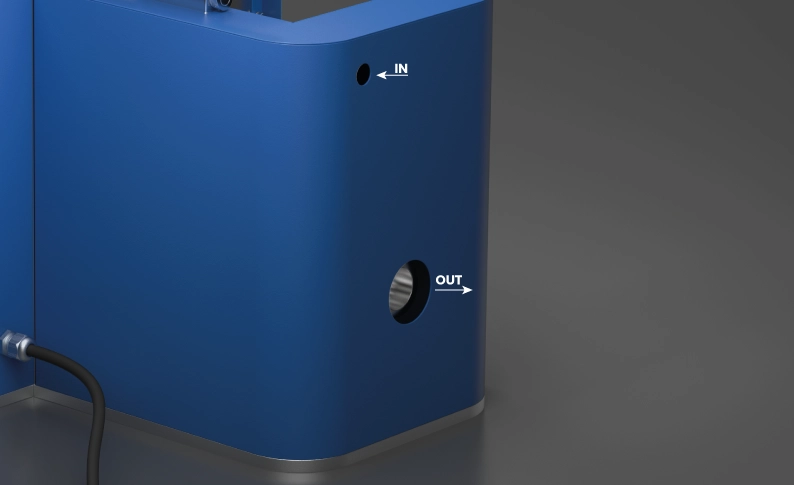

Water Feed and Discharge

Provision for the inlet of working water, ensuring adequate cooling flow. Outlet for collecting working water, which can be directed to the laboratory’s recirculation system.

![]()

Wrench

Included wrench for unscrewing the bolt and quickly changing the cone with ease.

![]()

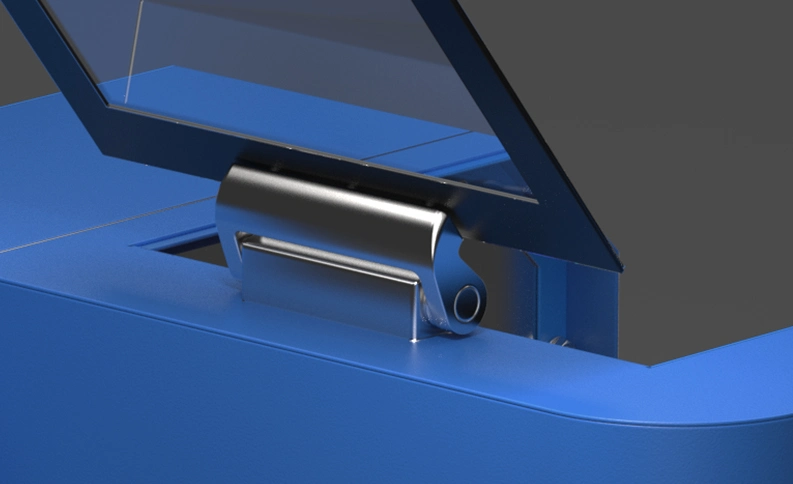

Safety Hinges

The covers are equipped with safety hinges. If a cover is opened, the machine automatically stops, ensuring maximum safety for the operator.

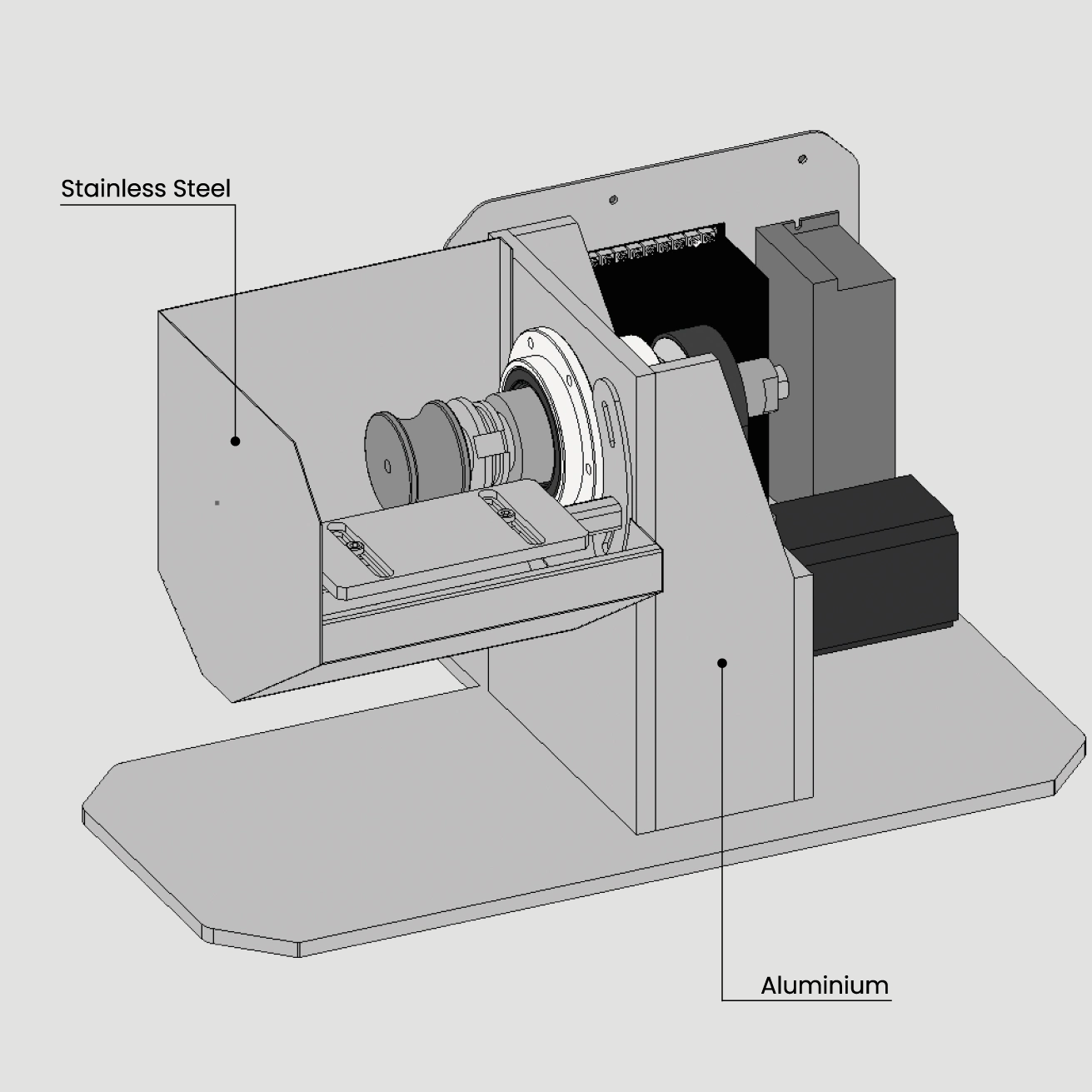

MARMO SHARPENER:

Built to Last

The MARMO SHARPENER is entirely constructed from stainless steel and aluminum, materials chosen to ensure maximum durability and resistance over time. This combination also provides superior resistance to corrosion, wear, and environmental stress.

These long-lasting materials reduce the need for maintenance and replacement. The MARMO SHARPENER is ideal for those looking for a reliable product that will ensure excellent performance for decades.

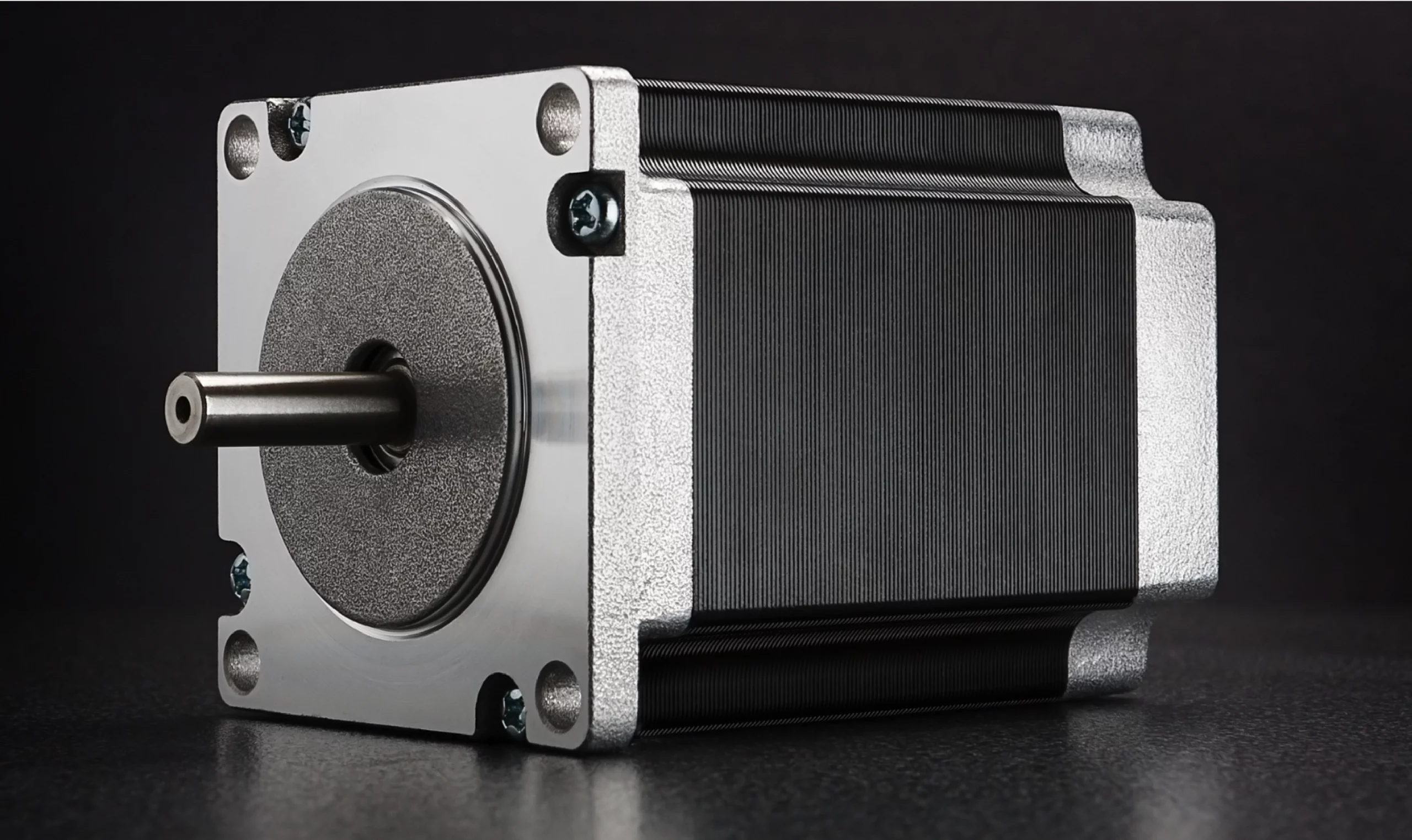

Brushless Motor:

Efficiency and Superior Performance

The MARMO SHARPENER is equipped with a state-of-the-art brushless motor, a technological choice that offers numerous advantages in terms of efficiency and performance. The brushless motor, being devoid of brushes, significantly reduces internal friction, ensuring smoother and quieter operation.

The MARMO SHARPENER with a brushless motor represents the pinnacle of technology in terms of mechanical and electrical efficiency, guaranteeing users superior performance and reduced operating costs, making every job simpler and more productive.

![]()

Energy Efficiency

Brushless motors are known for their high energy efficiency. They consume less power and produce more output per watt compared to traditional brushed motors, reducing operational costs and environmental impact.

![]()

Increased Durability

With no brushes, the brushless motor has fewer parts that wear out, significantly extending the motor’s lifespan. This translates into less maintenance and fewer replacements needed.

![]()

Enhanced Performance

The brushless motor ensures constant power output at both low and high speeds, thus ensuring maximum performance.

![]()

Reliability

With fewer mechanical components subject to wear, brushless motors offer greater reliability and consistent performance, even under heavy loads and in challenging operational conditions.

100% Made in Italy –

100% Made in Marmoelettromeccanica

Our production is proudly 100% Made in Italy and 100% Made in Marmolettomeccanica. We guarantee the entire production process internally, from structural and electrical design, to CNC programming, rubber molding, and the creation of electrical systems and software.

Even post-sales support and installation are managed internally by our specialized staff. This commitment allows us to ensure the highest quality of our products, maintaining total control over every aspect of production.

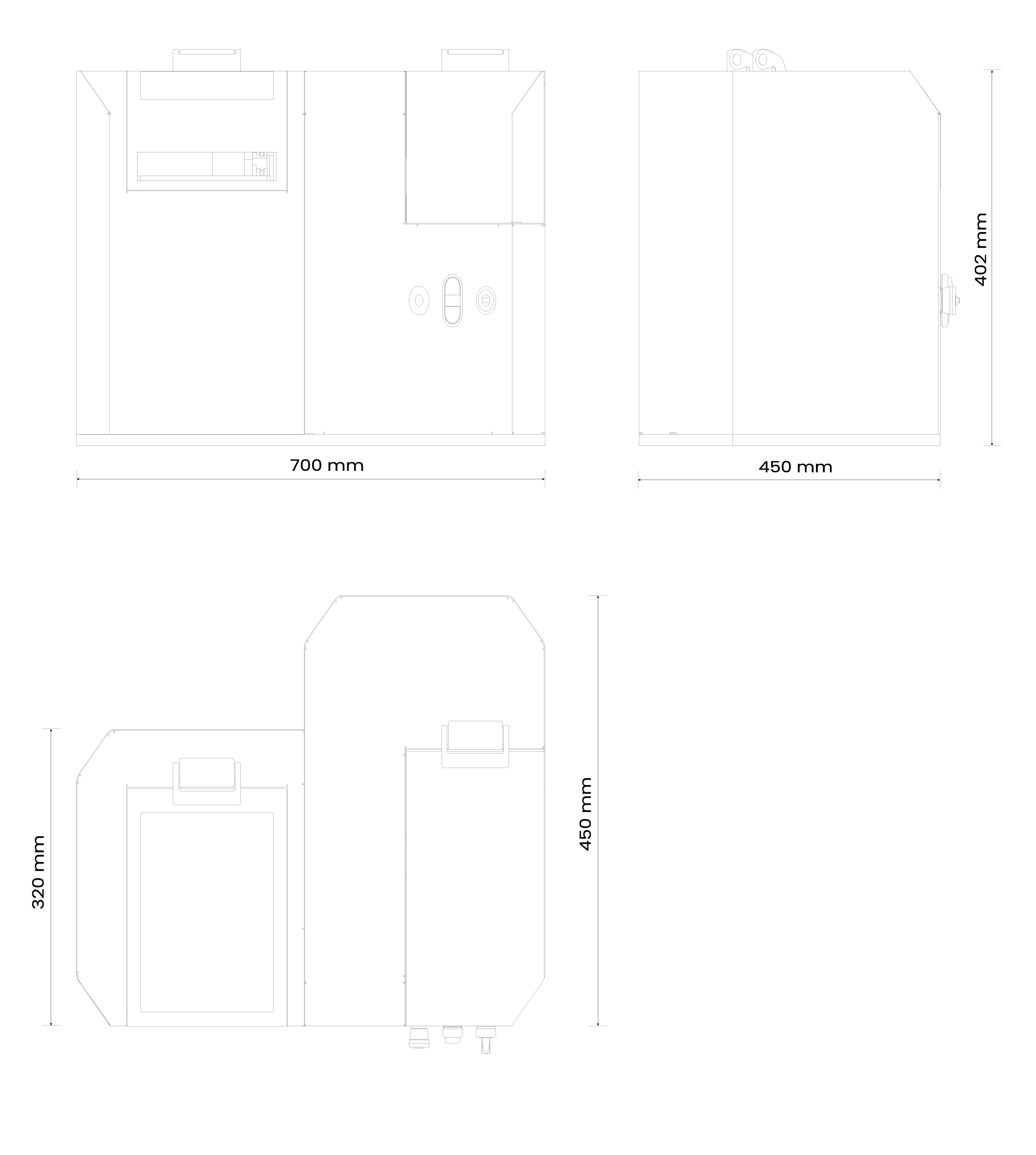

Technical Drawing

MARMO SHARPENER

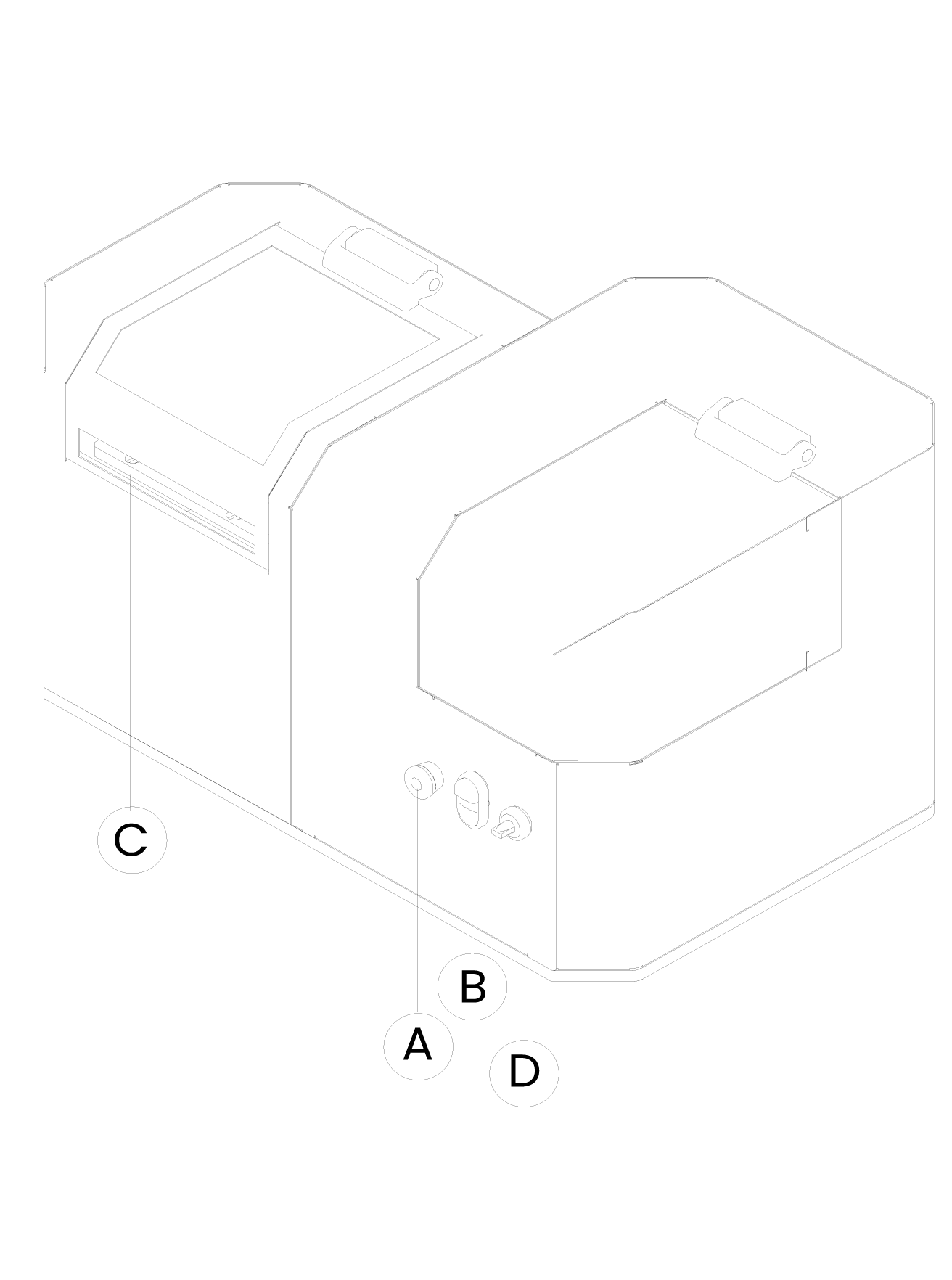

Detailed description

A- Stop Button. Red stop switch is marked with “OFF” gives you the possibility to quickly turn off the machine even in an emergency.

B- On-off button. Pressing the power button is highly visible and easy to use, allows the operator to start and stop the machine’s operational cycle.

C – Abrasive slot. Ensures a secure and stable housing of the abrasive during operation.

D – Speed Regulator. The dedicated knob allows for complete control of the grinding wheel speed.

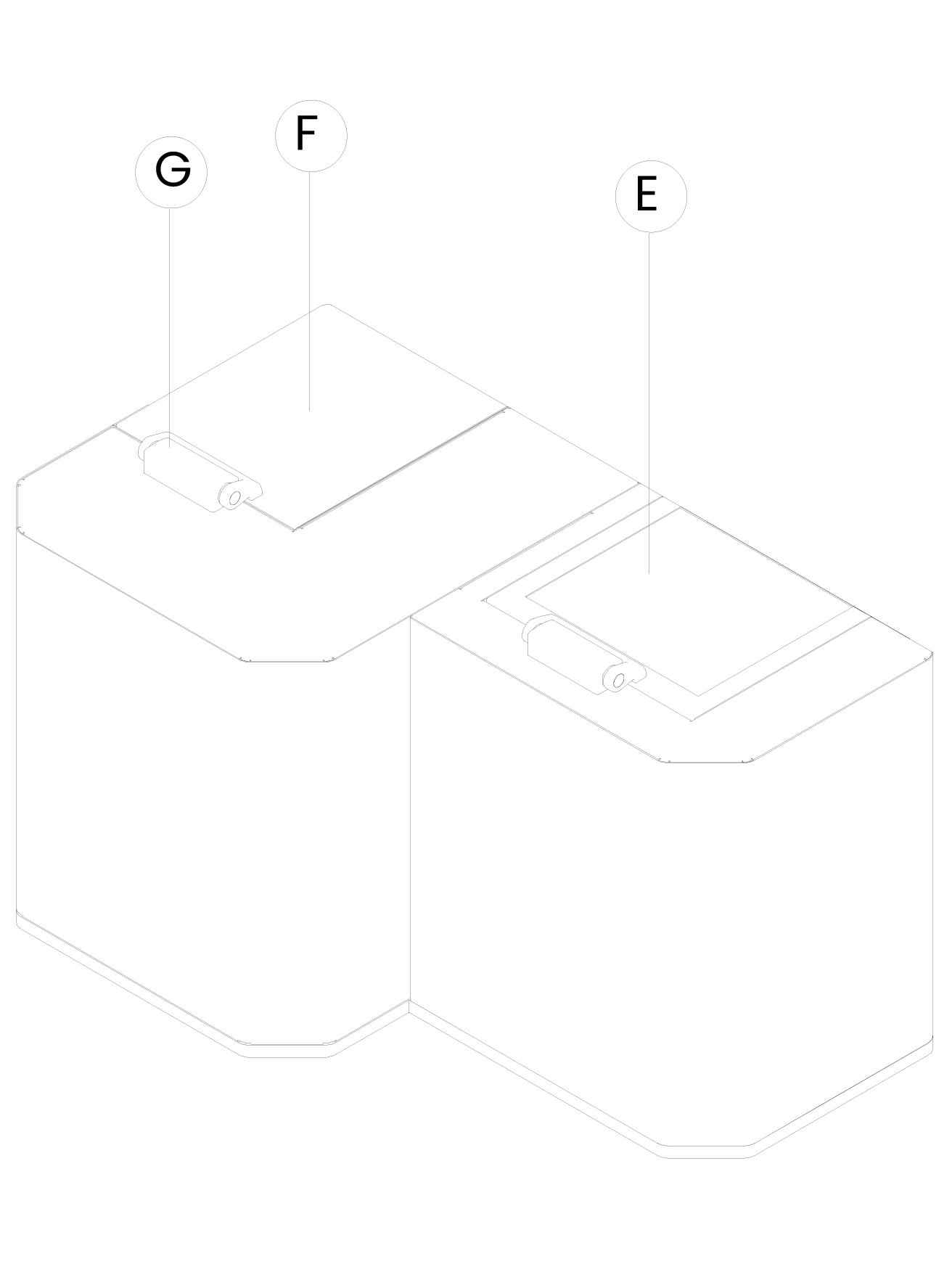

G- Stainless steel hinge. The stainless steel hinge ensures robustness and durability, offering high resistance to corrosion.

E / F- Plexiglass Cover. The safety covers are designed to ensure maximum safety for the operator during machine operation. They offer excellent visibility of the work area, allowing the operator to monitor the process without compromising their safety.

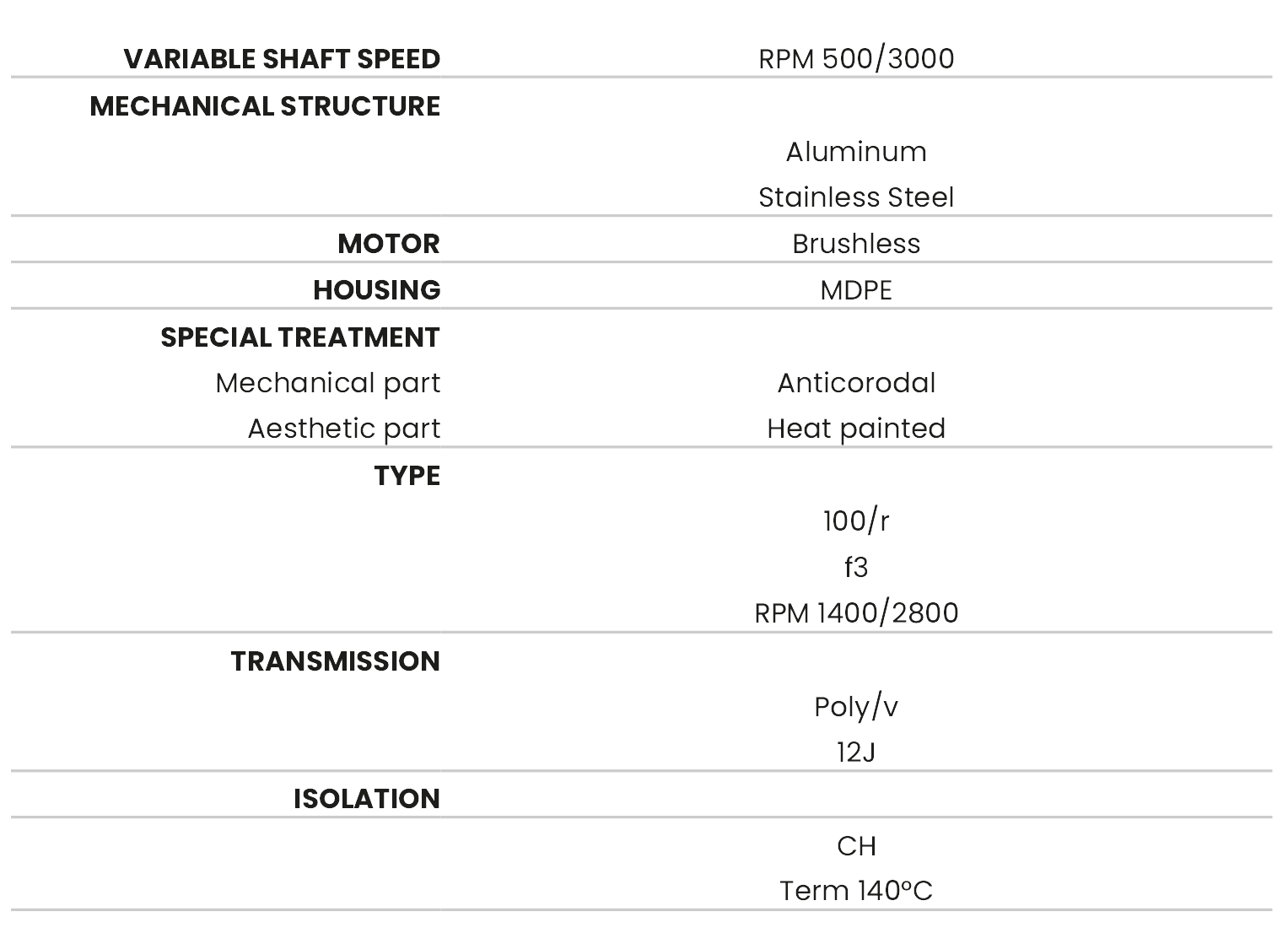

Technical Data