MARMO VIEWER 3D

MARMO VIEWER 3DML

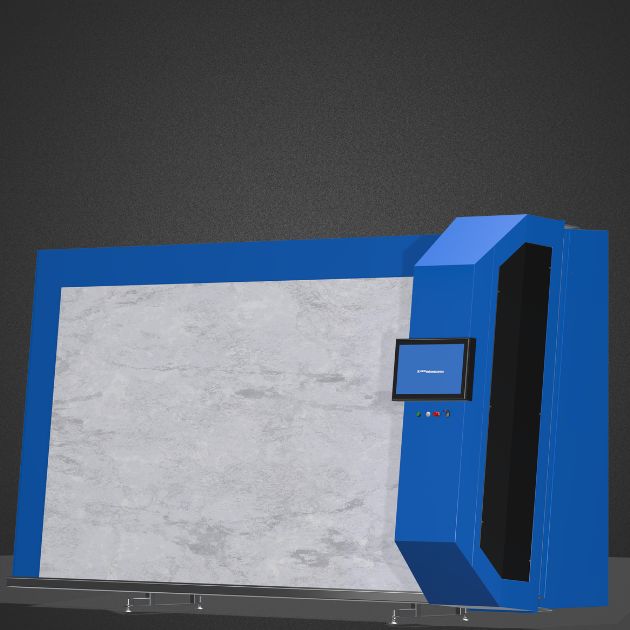

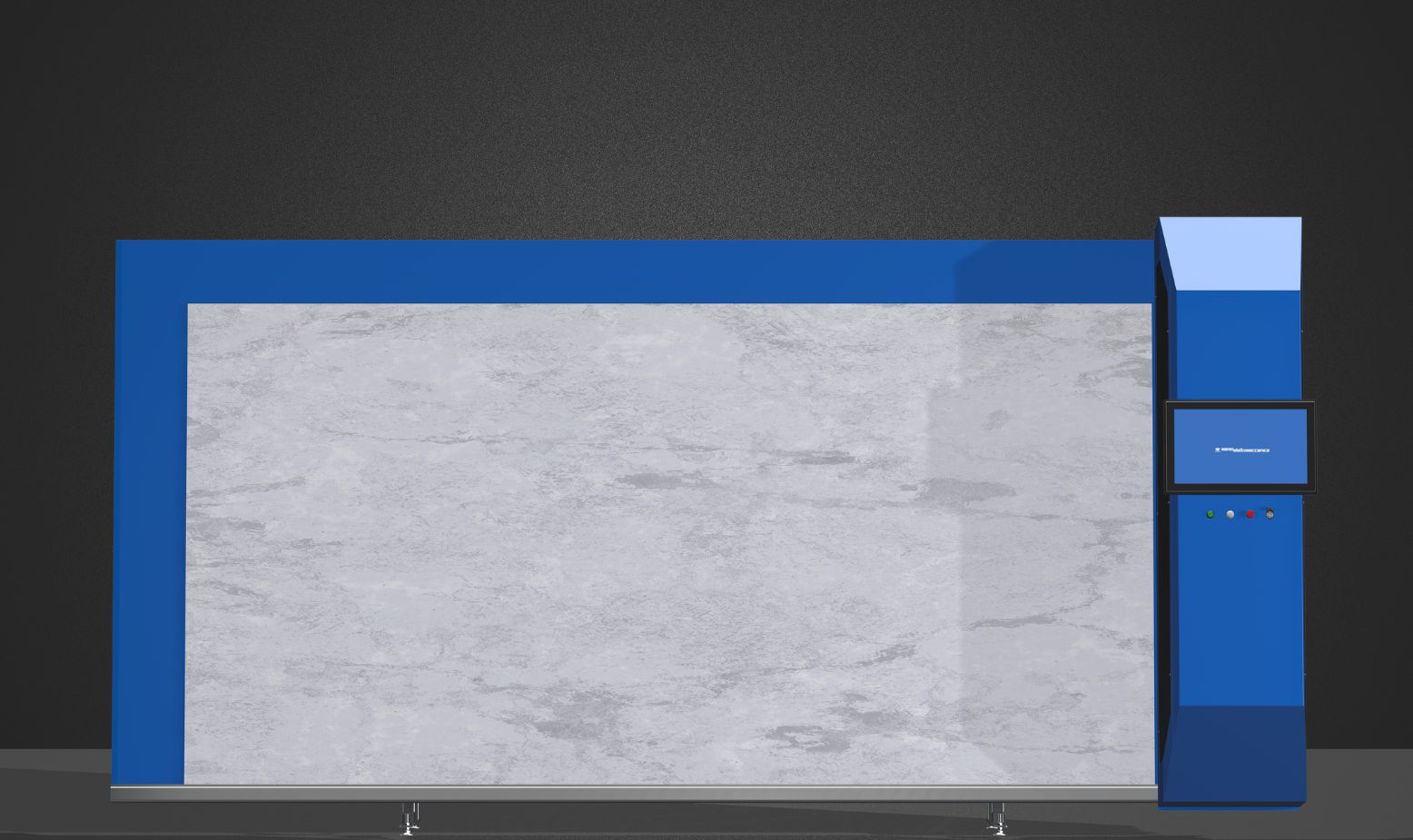

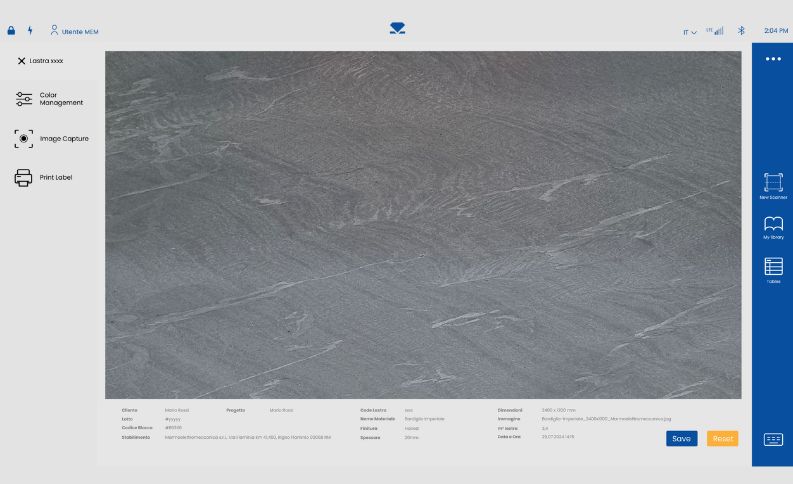

Thanks to a set of ultra-high-resolution cameras, this machine can accurately capture every detail of the veins, colors, and unique characteristics of natural stone slabs.

Why process with MARMO VIEWER 3D?

This technology allows clients to view precise images of marble slabs, highlighting their beauty and uniqueness remotely.

The ultra-high-resolution scans provide a realistic preview, eliminating surprises during installation. Additionally, it optimizes inventory management by allowing slab selection directly from a digital database, without the need for physical inspections.

![]()

Precision

Every detail of the slabs captured with exceptional clarity.

![]()

HD Images

The result is a library of ultra-high-resolution images.

![]()

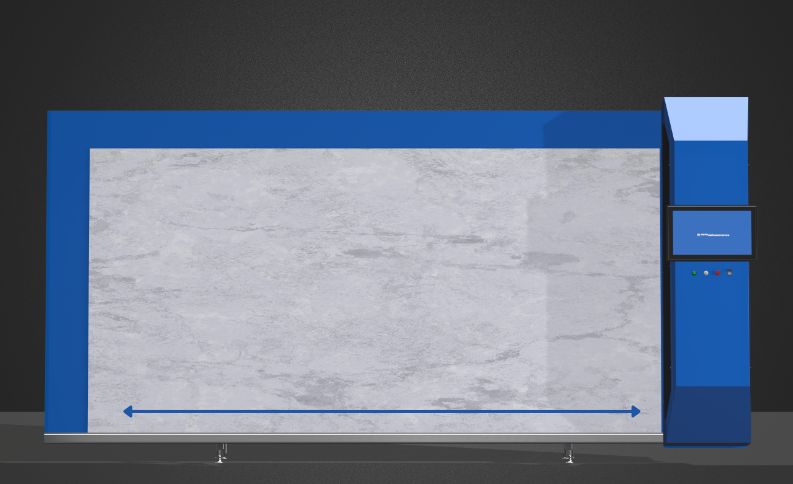

Max slab dimensions

4000x2200mm to ensure compatibility with a wide range of formats.

![]()

Touch-Screen

A large touchscreen ensures simple and intuitive machine control.

Main Functions

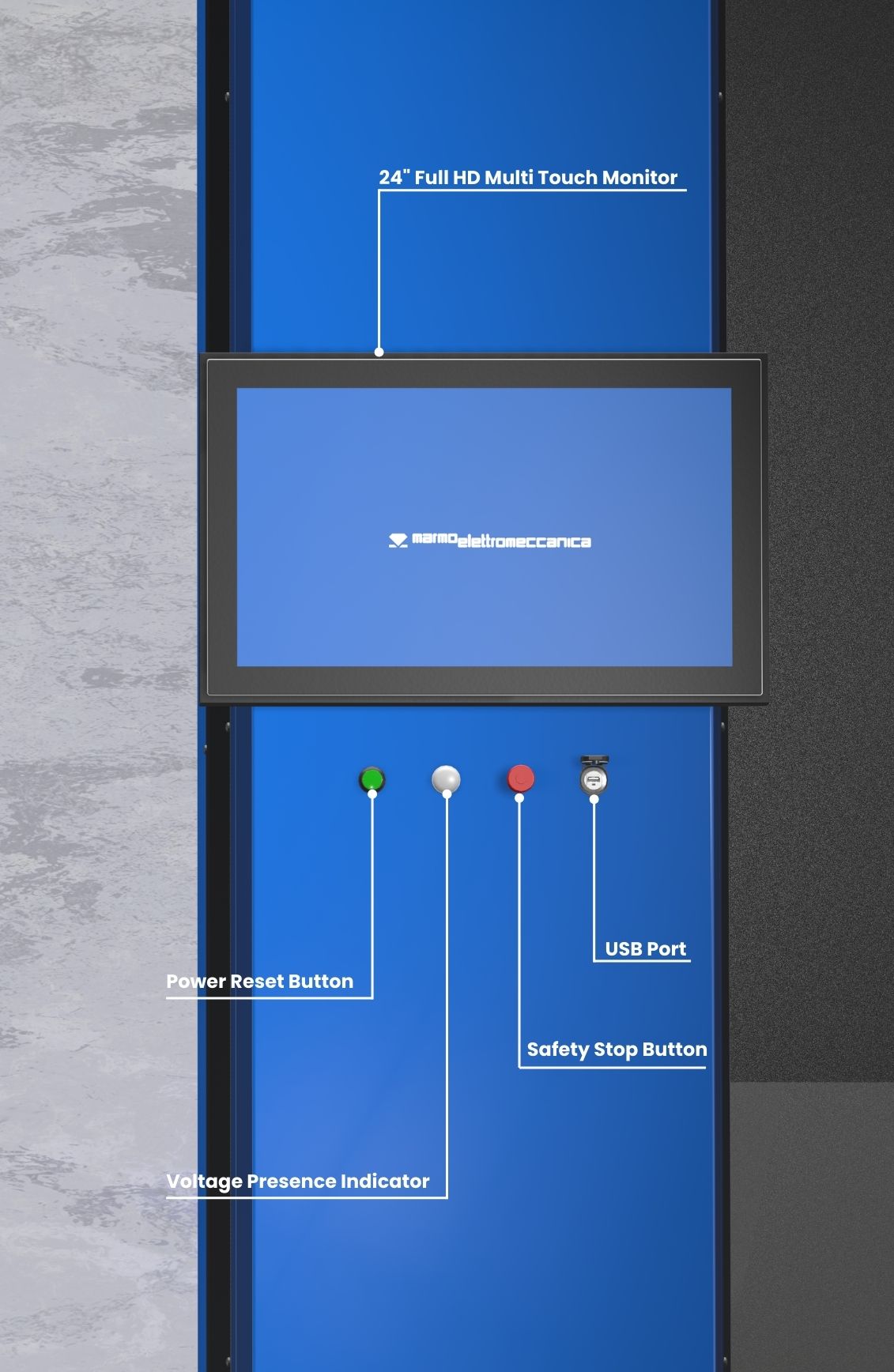

Buttons and Indicator

The system ensures maximum operator safety by allowing the immediate interruption of machine operation in emergency situations with the red button, while the green button enables a safe power restoration and machine restart after an emergency stop. Additionally, the white light indicates the presence of voltage, confirming that the machine is properly powered and ready for use.

24″ Full HD Multi Touch Monitor

For simple and intuitive machine control. Thanks to touch functions, a wide display, and a user-friendly interface, the operator can easily navigate through settings, view scanned slabs, and manage the image database with ease.

USB Port

The machine is equipped with a USB port to connect devices such as printers or external storage devices.

High Resoultions Images

With the MARMO VIEWER 3D, you can scan stone slabs up to 4000×2200 mm and obtain an image with 12K resolution (12288×6480 px).

Output File

![]()

LXH

The scan provides the exact shape of the slab

![]()

DXF

Standard file for CAD software

![]()

SVG

Vector file for versatile use

![]()

JPG

HD image file for archiving and sharing

Panel PC

For total and intuitive control of the machine form a single large screen.

![]()

Full HD

Full HD resolution for optimal viewing of controls and settings.

![]()

Touch Function

Touch screen for simple and immediate control.

![]()

Technology

User-friendly Interface with intuitive controls.

Machine

Movements

Horizontal Movement

The MARMO VIEWER 3D moves smoothly along the longitudinal axis of the slab, performing a perfect scan of the entire surface. In this way, every detail is captured with maximum accuracy, ensuring a faithful reproduction of the slab.

Within the scanning unit, the machine is equipped with a controlled lighting system, designed to operate in an enclosed environment.

This feature is essential for accurately preserving the natural colors and veining of the marble, eliminating external influences such as reflections or light variations, and ensuring images that precisely reflect the real appearance of the slabs.

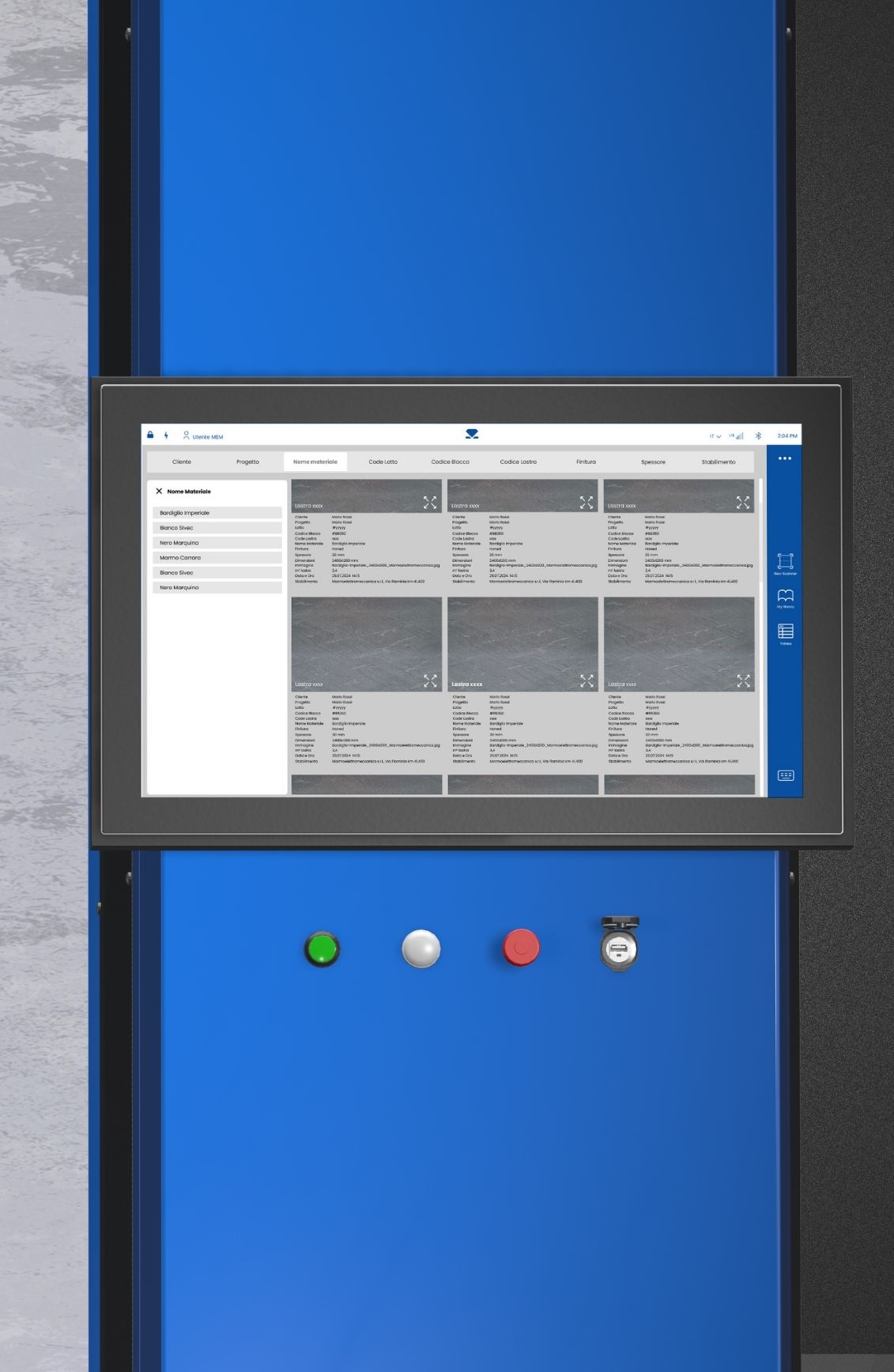

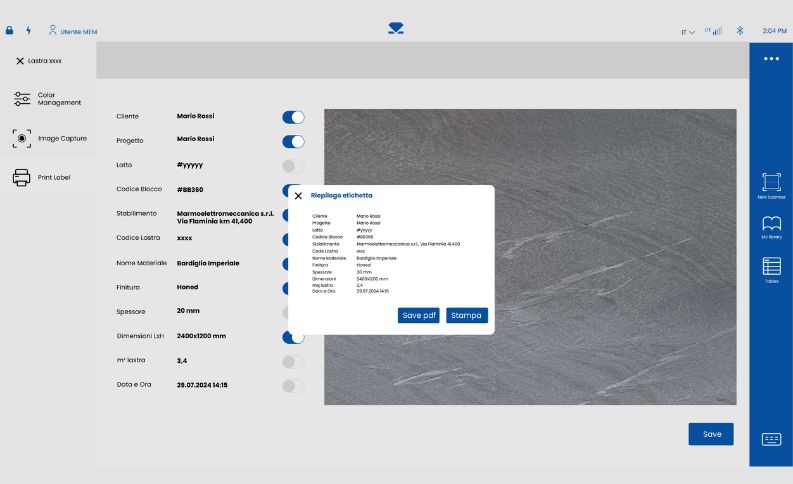

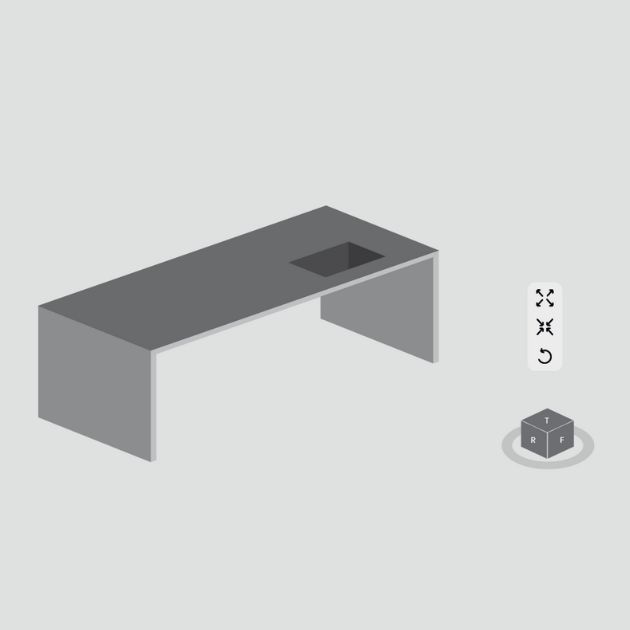

Dedicated software to

speed up the workflow

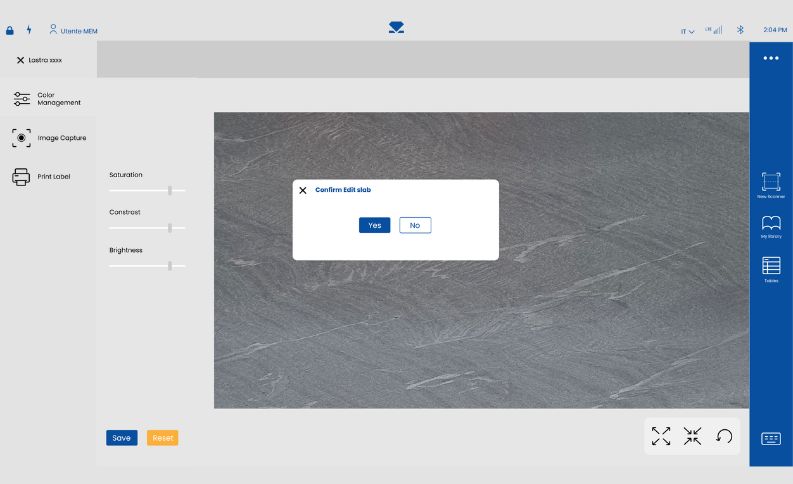

The machine’s software has been specifically designed to optimize slab scanning, ensuring maximum control and precision.

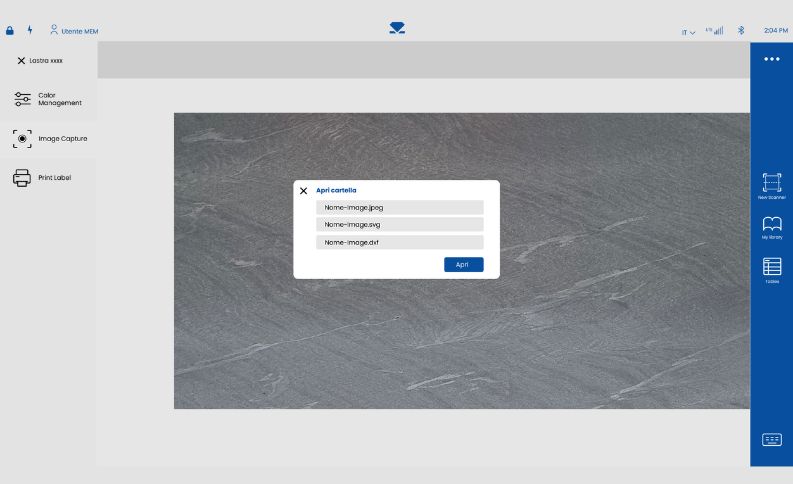

Among its main features are color correction, the ability to directly print labels with various details, and the creation of an archive and library to effectively manage all scanned images.

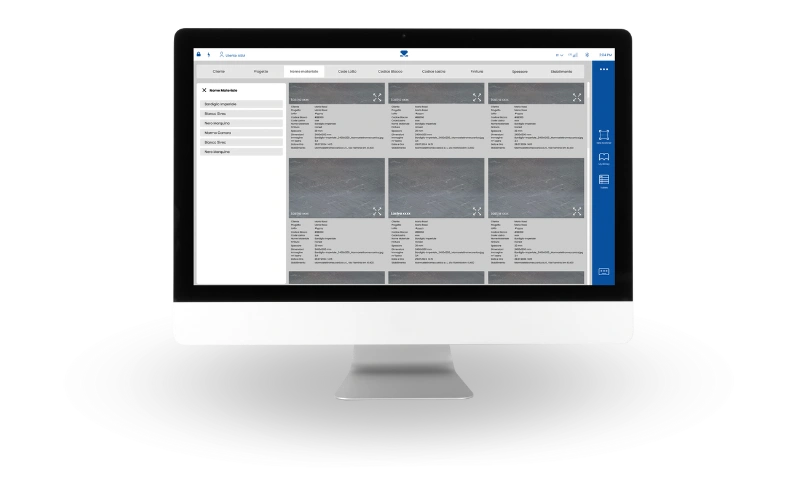

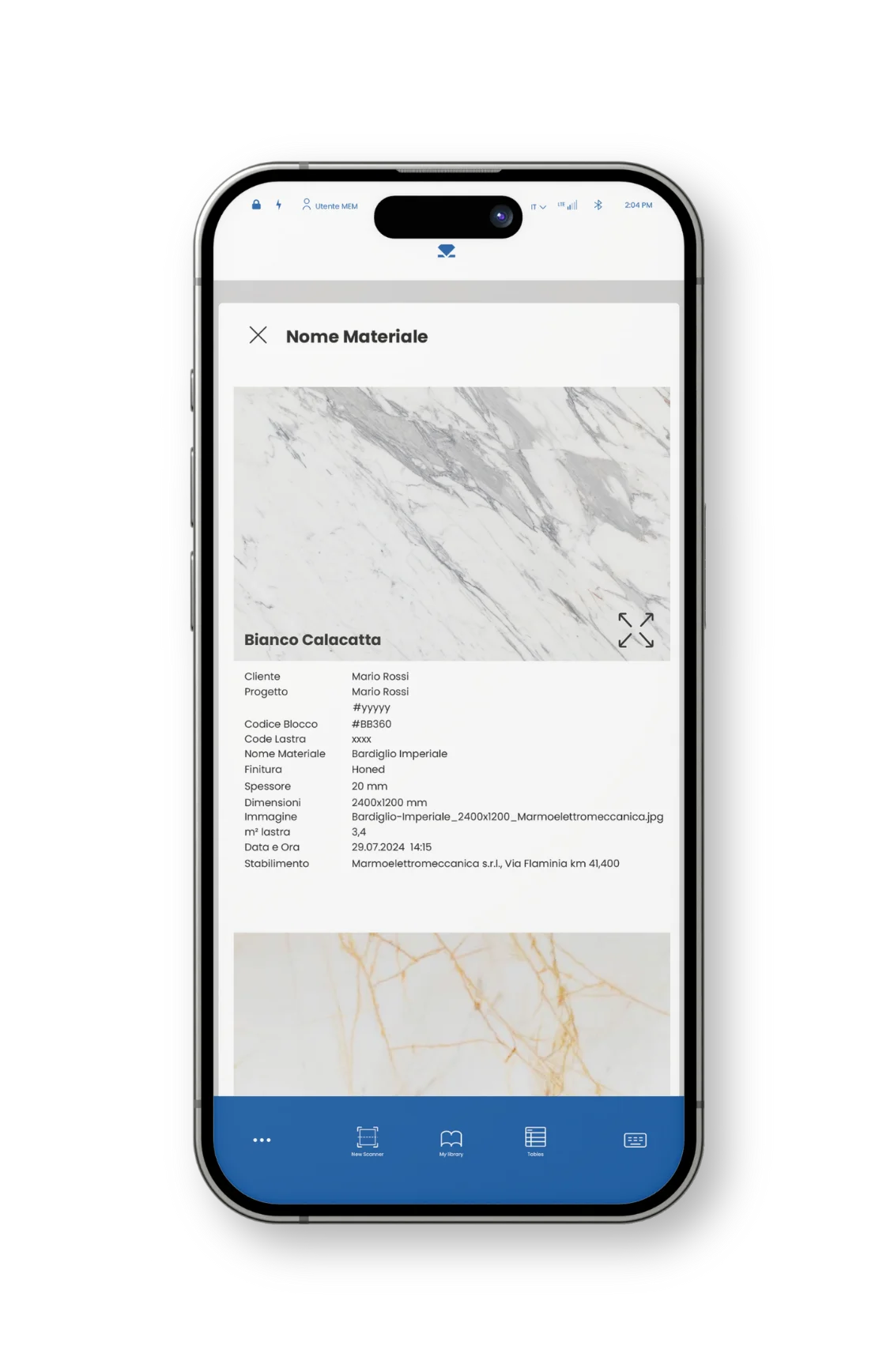

Through a dedicated web app, fully tailored to its functionalities, this system allows the management of all images, labels, and slab archives directly online via an internet connection.

![]()

Out put scan

Exact slab dimensions. Total surface area expressed in square meters. Technical specifications.

![]()

Color Correction Image

Thanks to this feature, the visual fidelity of the scanned images can be optimized. If slight adjustments are needed, corrections can be made directly from the monitor integrated into the machine.

![]()

Export File

The machine allows exporting files in various formats:

JPEG: high-resolution images of the slabs, ready to be shared or archived;

SVG: vector format for various types of use;

DFX: standard format for integration with CAD design software.

Print File

Labels can be printed and customized according to the customer’s needs.

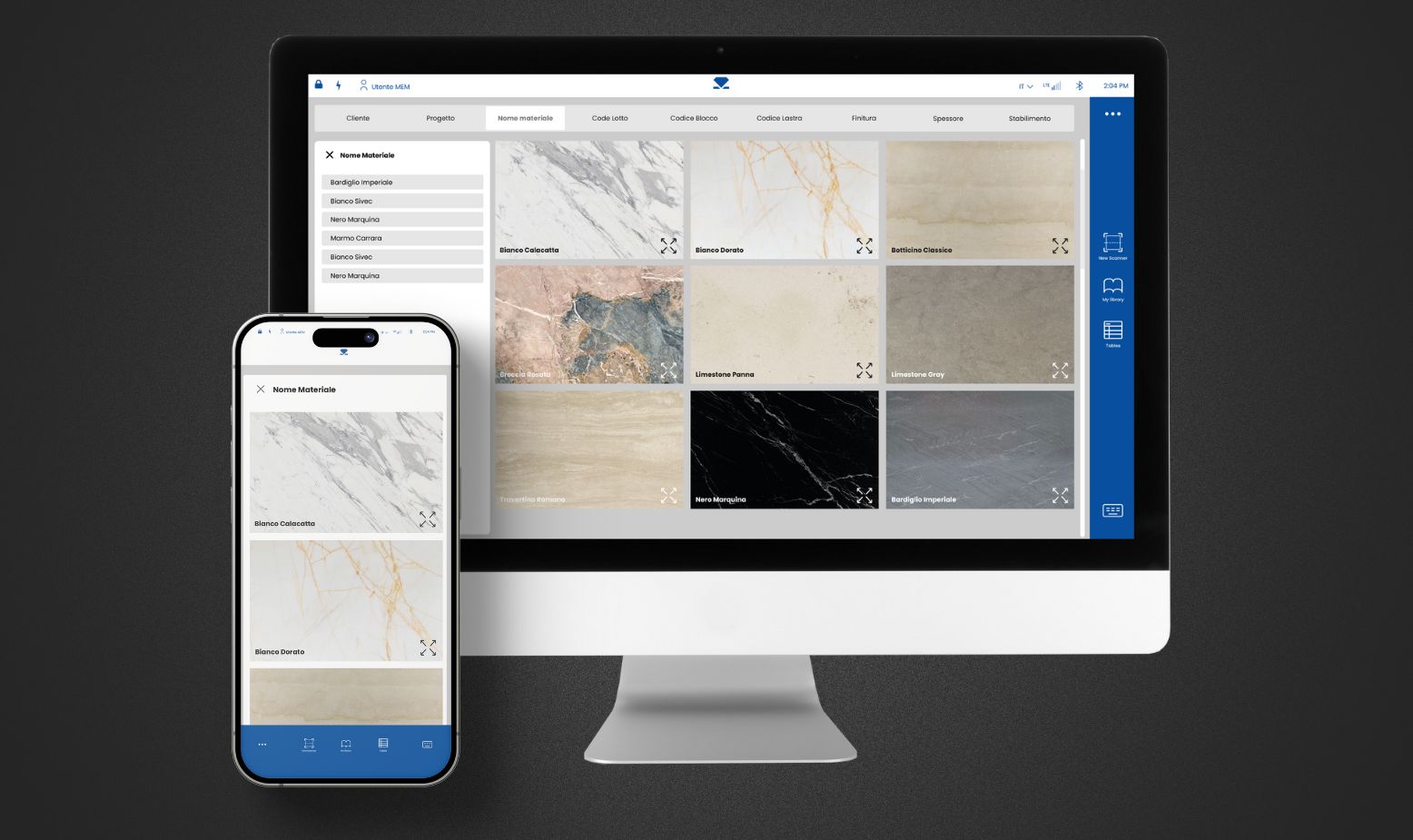

Images

Library

The machine is equipped with a dedicated section for managing the image library, where all scanned slabs are stored in an organized database.

This system allows filtering images by various categories, such as material type, customer, or finish, making slab search and management simple and intuitive.

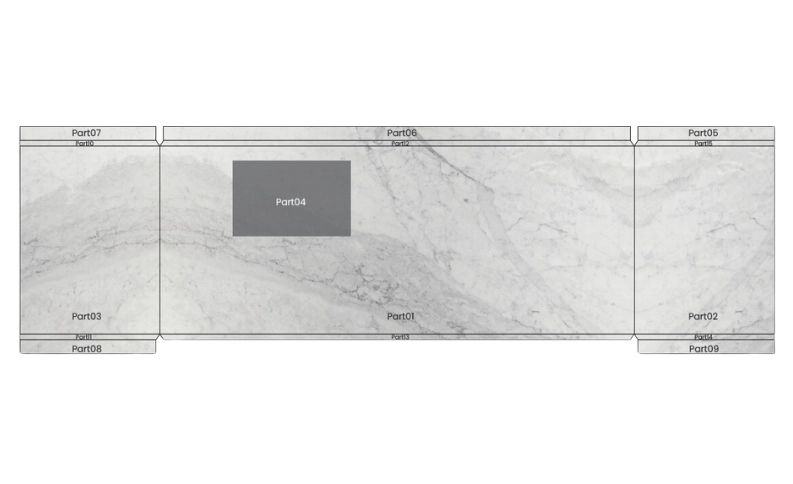

Switch for

Vein Matching

Vein Matching is an advanced optional software used to manage and optimize the virtual alignment of scanned slabs, ensuring that the marble veining perfectly matches the various projects.

Vein Matching is an optional feature available upon request, ideal for those seeking to achieve perfect visual continuity in projects, enhancing the aesthetic effect of marble or natural stone.

Smartphone Acces

With remote access via smartphone, users can monitor the machine’s activity and performance in real time, easily overseeing its operation and functionality from their mobile device.

PC Access

Our machine is designed to be connected to external PCs for the implementation of additional functions, such as database management or remote assistance.

Remote Support

ON-LINE SUPPORT

Experience superior online support for our products. Our experts provide real- time assistance, tailored recommendations, and innovative solutions for precision machining, ensuring optimal performance and productivity in every operation.

ONSITE SUPPORT

Elevate your work with our onsite support for our products. Our experts bring tailored recommendations, real-time assistance, and innovative solutions to your location, ensuring optimal precision and productivity

in every operation.

MARMO VIEWER 3D:

Built to Last

The MARMO VIEWER 3D is entirely constructed from high-strength materials, selected to ensure maximum durability and long-term resistance. This combination also offers superior protection against corrosion, wear, and environmental stress.

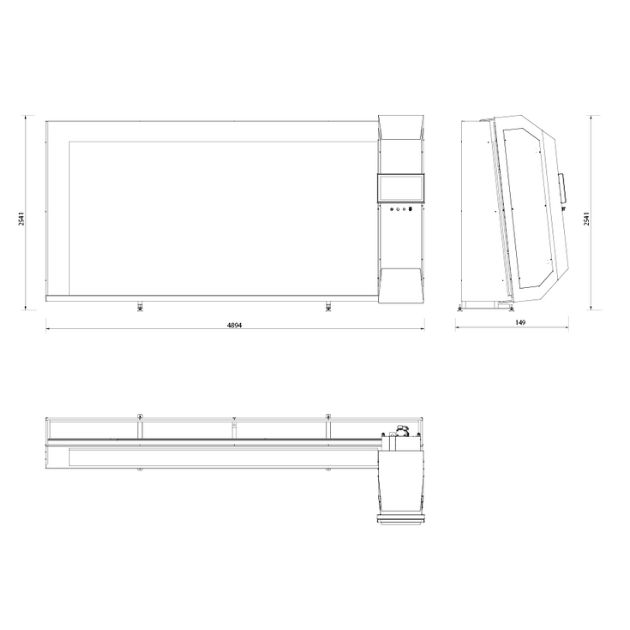

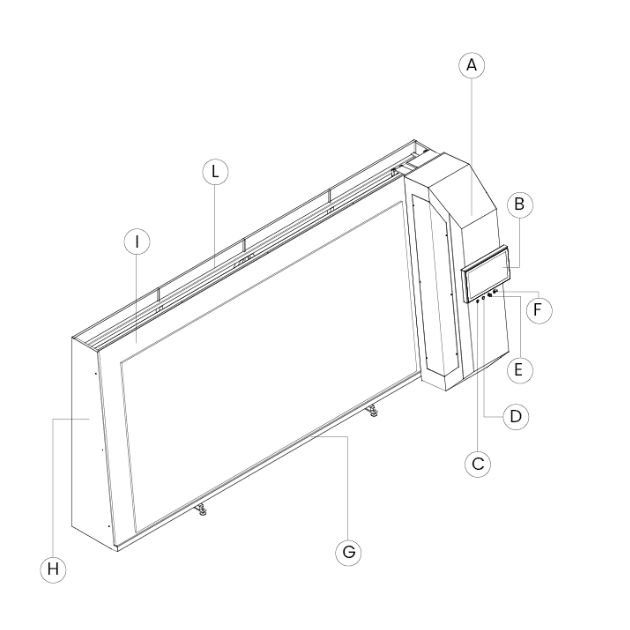

Technical Drawing

Detailed description

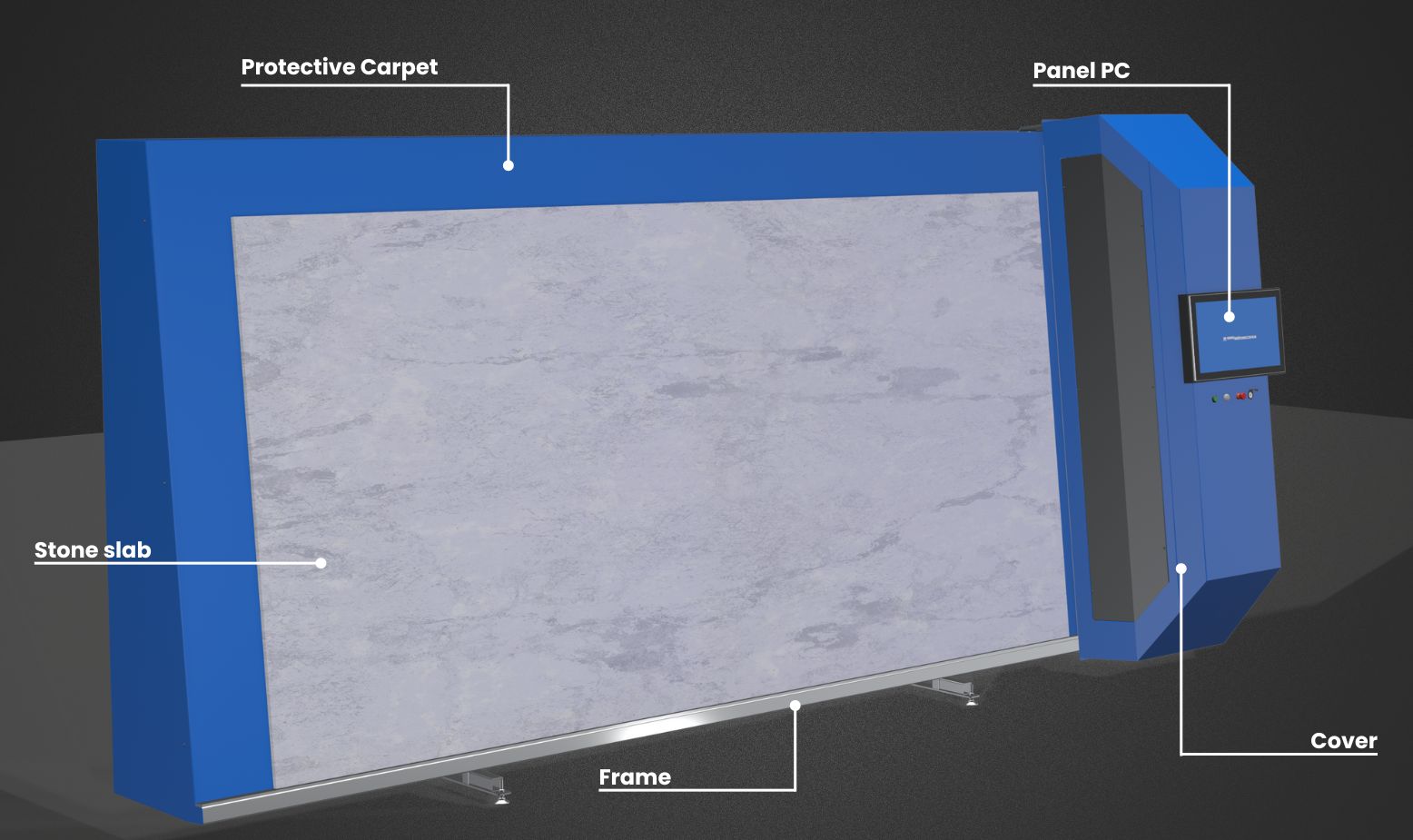

A – Scanner Block. Set of hardware and software components for scanning.

B – Panel PC 24’’. Large 24” screen with Full HD resolution and multi-touch functionality.

C – Power Reset Button. Restores the machine’s power supply.

D – Power Indicator Light. Signals that the machine is properly powered.

E – Emergency Stop. Button to stop the machine at any time in case of emergency.

F – USB Port. USB input for connecting external devices such as printers or storage devices.

G – Structure. Painted iron frame.

H – Cover. Protective casing.

I – Slab Support Carpet. Carpeted surface for slab support to ensure protection.

L – Substructure. Iron frame and carpentry structure.

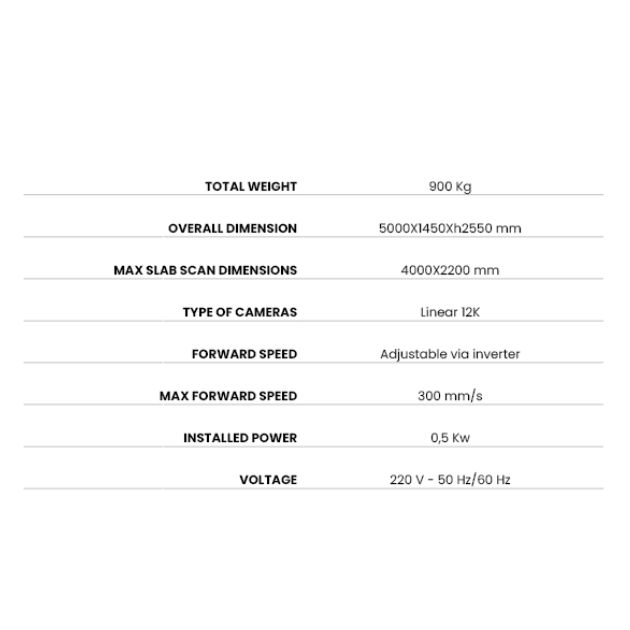

Technical Data