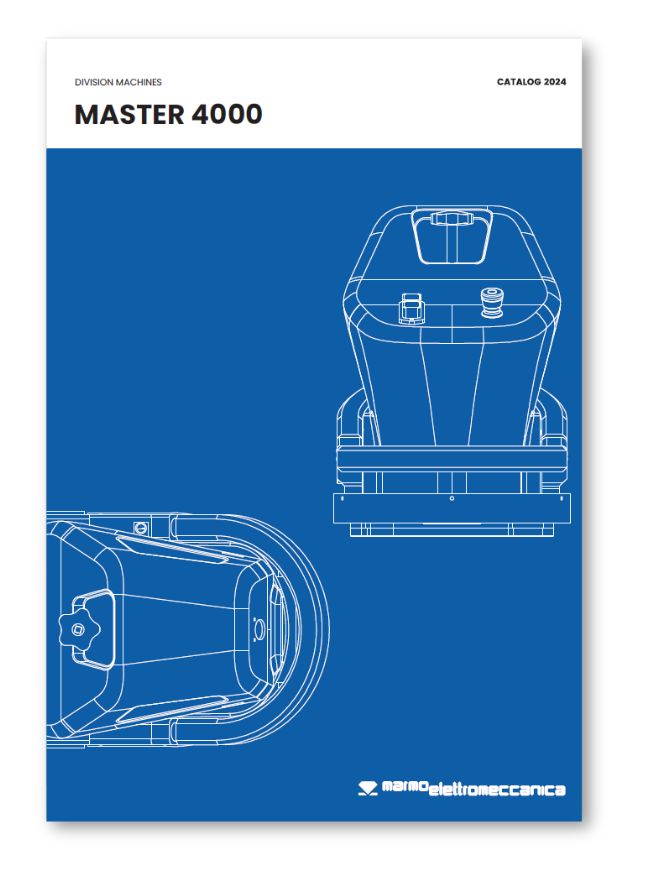

MASTER 4000

MASTER 4000

The MASTER 4000 is a solid and robust manual machine designed for stone processing. With just a few simple adjustments, it is ideal for shaping profiles quickly and efficiently.

Why process with MASTER 4000?

The MASTER 4000 is the choice of professionals seeking a portable shaping machine that makes the stone processing fast, practical, and easy.

This manual contouring machine offers manufacturers the ability to work with any material in complex shapes, providing a high-quality product and significant time savings.

Profiling

Main functions

![]()

Manual Z-Axis Adjustment

The manual adjustment of the tool on the Z-axis via the practical knob makes the MASTER 4000 suitable for various types of work.

![]()

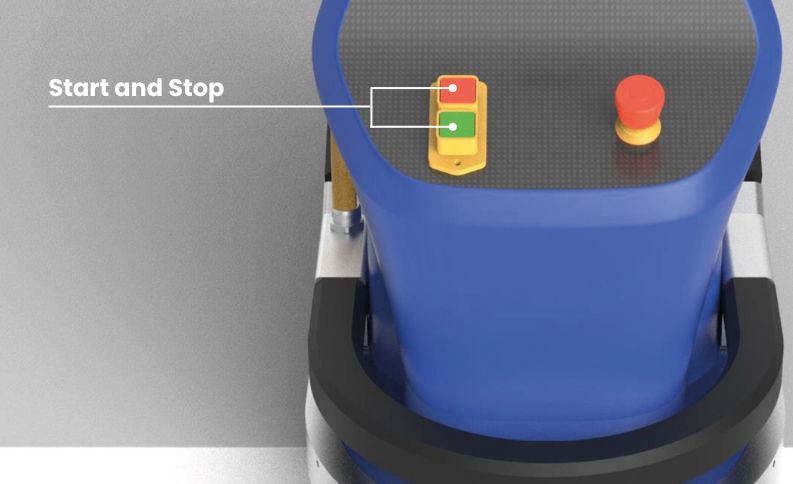

Start – Stop

To start and finish the processing easily and safely.

![]()

Safety Button

Safety in the workshop is paramount, and the MASTER 4000 is designed with the operator’s peace of mind in mind. The “Off” button of the MASTER 4000 is backlit to ensure optimal visibility in any situation. This feature allows operators to clearly see if the machine is in operation and to act quickly in case of an emergency.

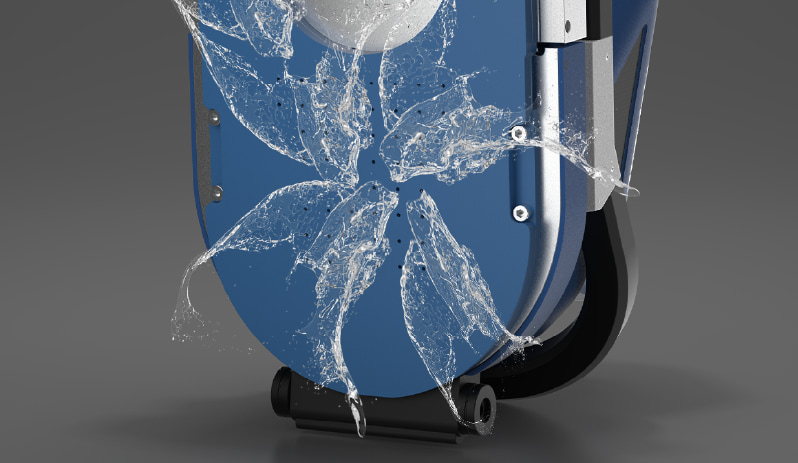

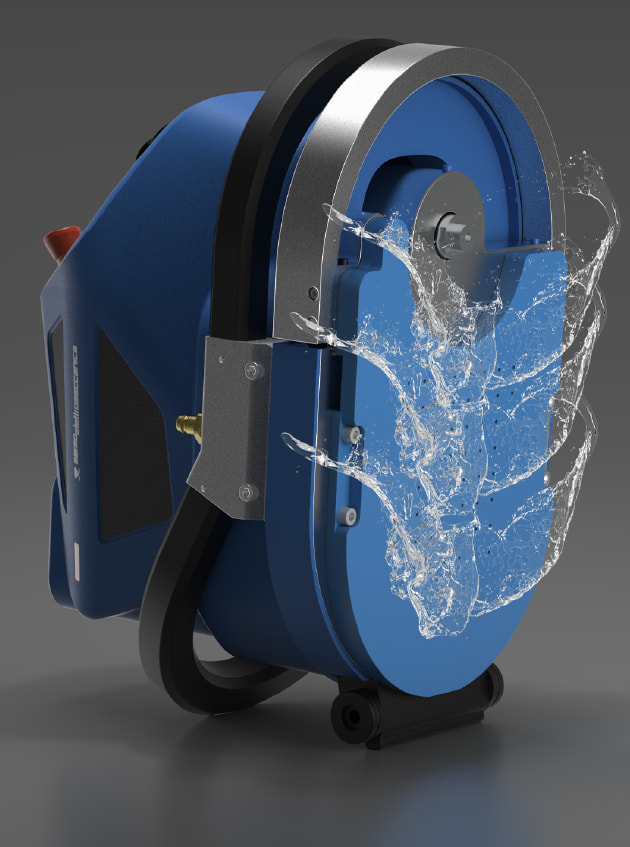

Water System Plate

The Water System Plate is designed to enhance performance by allowing it to glide over a thin film of water. This unique feature ensures exceptionally smooth operation, preventing scratches on the surfaces of the materials being processed.

Smooth Operation

The water film between the machine and the material ensures that the MASTER 4000 moves effortlessly, reducing friction and preventing scratches on delicate surfaces.

Unique Design

Developed by Marmoelettromeccanica, this system is considered the best on the market. Its design not only improves operational fluidity but also contributes to the overall efficiency of the MASTER 4000.

Reliability and Durability

The Water System Plate is built to last. It does not clog or stop, ensuring continuous operation and long-lasting performance.

Safety and Efficiency

at Low Voltage

The MASTER 4000 is designed to ensure maximum safety in any work environment, operating at a low voltage of 48 volts. This makes it particularly safe for operators working in the presence of water. The low voltage also ensures the power and effectiveness of the machine, delivering high performance in all conditions of use.

The MASTER 4000 combines advanced technology with uncompromised safety, setting new standards in the industry for operator protection and operational effectiveness.

![]()

Smooth Operation

Operating at only 48 volts, the Master 4000 provides a safe working solution even in damp environments. This aspect is crucial for preventing injuries and ensuring workplace safety.

![]()

Unique Design

Its compatibility with wet environments makes it the ideal choice for sectors such as marble processing and other applications that require the presence of water during the process.

![]()

Reliability and Durability

Thanks to its low voltage configuration and other integrated safety measures, the Master 4000 is considered the safest machine in the world in its category, offering complete peace of mind to operators.

Protection and Efficency

This machine is designed to operate at voltages of 110 volts or 220 volts, making it suitable for use in any workshop or construction site. This versatility in power supply ensures that the machine can be easily integrated into various work environments without the need for special adapters or transformers.

The MASTER 4000 combines excellent power and operational flexibility, setting new standards of versatility and reliability in its field, and ensuring high-performance levels in every usage condition.

PERSONAL PROTECTION INTERMEDIATE SWITCH

A safety switch against electric shocks, with undervoltage release and a response time of less than 30 ms. It detects faults and immediately cuts off the power supply. Compatible with cables up to 3G2.5mm², it supports 230 V, 16 A, 3,500 W, and has IP66 protection.

![]()

Dual Voltage Option

With the ability to function at both 110 volts and 220 volts, the machine offers unprecedented flexibility, easily adapting to both small artisan workshops and large industrial sites.

![]()

Guaranteed Power

A consumption of 1500W for 220 volts and 14Ah for 110 volts ensures that the machine has the necessary power for heavy and continuous operations, maintaining high standards of efficiency and productivity.

![]()

Ideal for Any Environment

Its ability to operate with different voltages makes it ideal for international use, overcoming barriers that often limit the use of heavy machinery due to local power specifications.

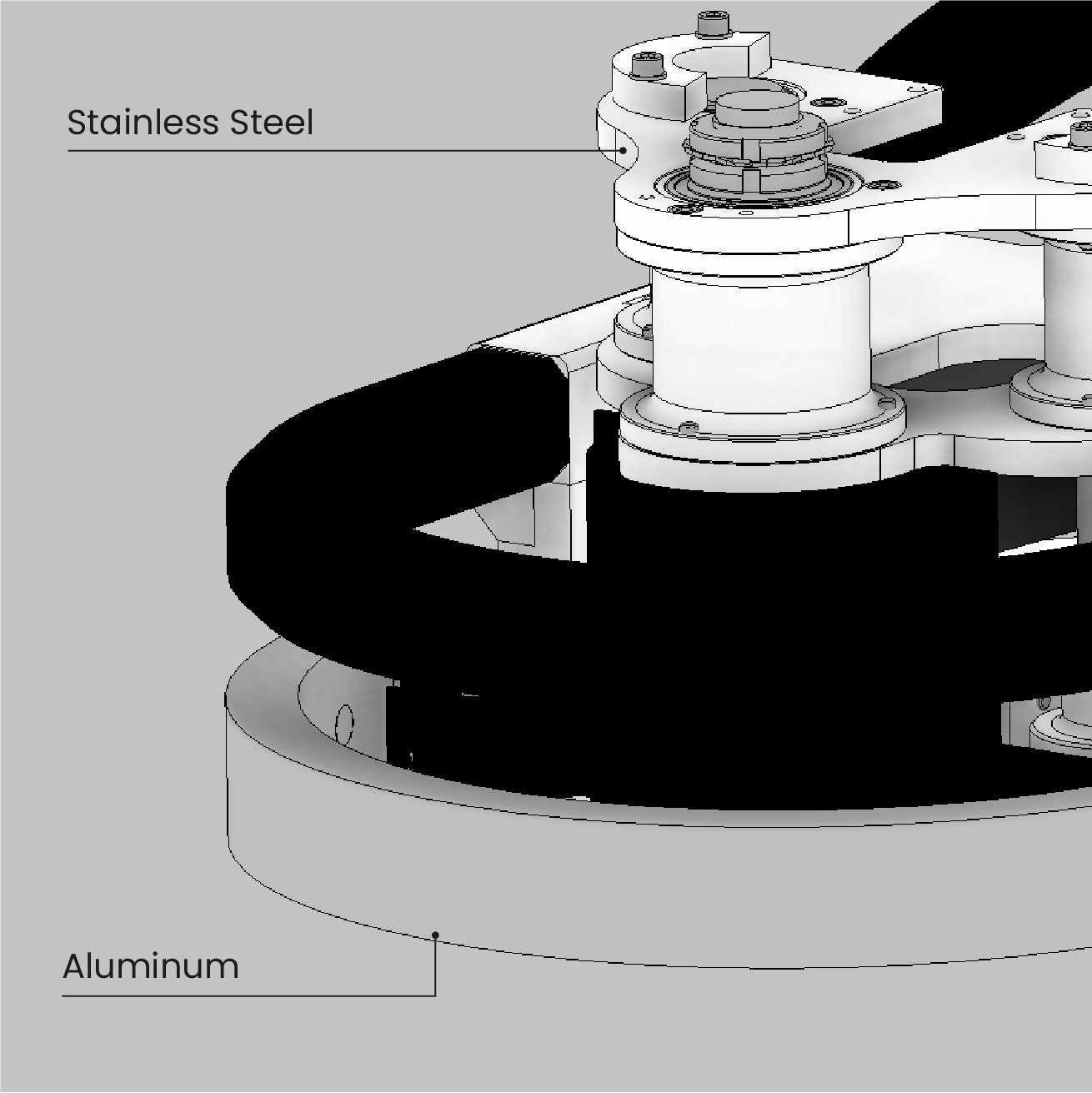

MASTER 4000:

Built to Last

This machine is designed to operate at voltages of 110 volts or 220 volts, making it suitable for use in any workshop or construction site. This versatility in power supply ensures that the machine can be easily integrated into various work environments without the need for special adapters or transformers. The MASTER 4000 combines excellent power and operational flexibility, setting new standards of versatility and reliability in its field, and ensuring high-performance levels in every usage condition.

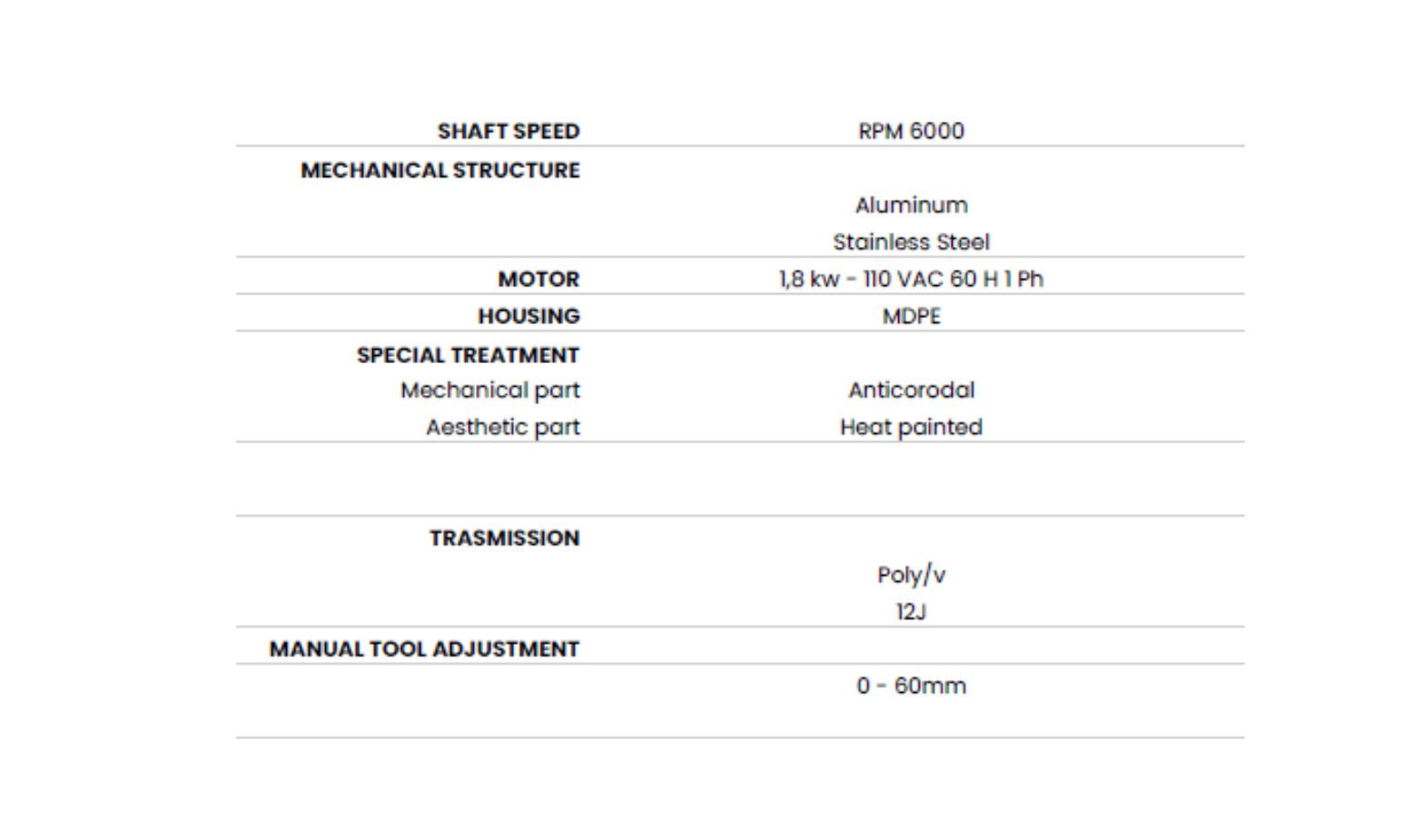

High-Efficiency Motor

and Superior Performance

The MASTER 4000 is equipped with a monophase motor, a technological choice that enhances both efficiency and ease of use. This single-phase motor is designed to deliver consistent power while simplifying installation and maintenance.

With this advanced motor, the MASTER 4000 represents the pinnacle of mechanical and electrical efficiency, providing superior performance and lower operating costs, making every task simpler and more productive.

![]()

Energy Efficiency

These motors are designed to optimize energy consumption while delivering consistent performance.

![]()

Increased Durability

The single-phase motor’s simplified design increases lifespan, requiring less maintenance and fewer replacements.

![]()

Enhanced Performance

The single-phase motor delivers consistent power at all speeds, ensuring maximum performance.

![]()

Reliability

With fewer mechanical components, the single-phase motor offers greater reliability and consistent performance, even under heavy loads.

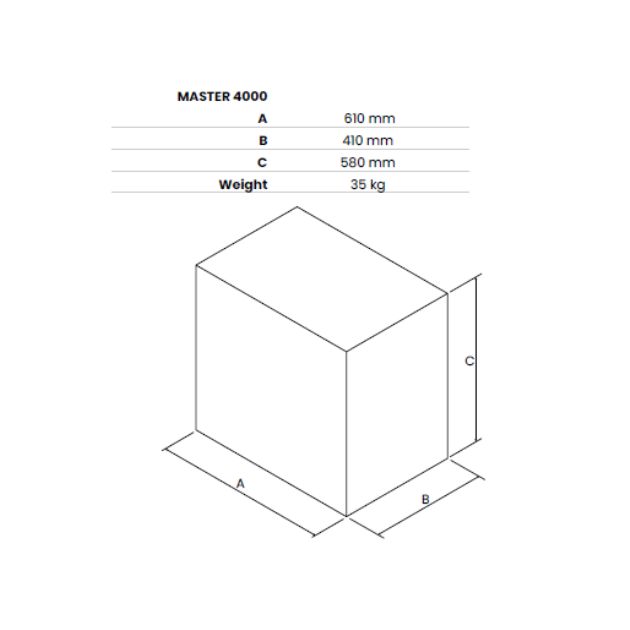

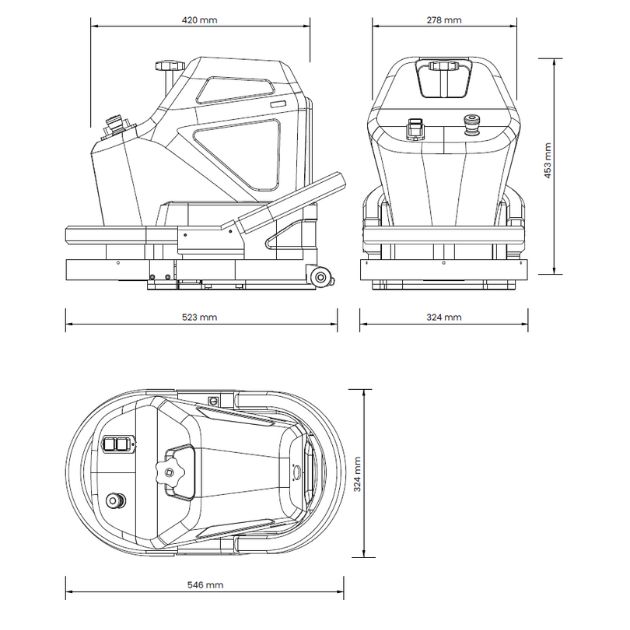

Technical Drawing

MASTER 4000

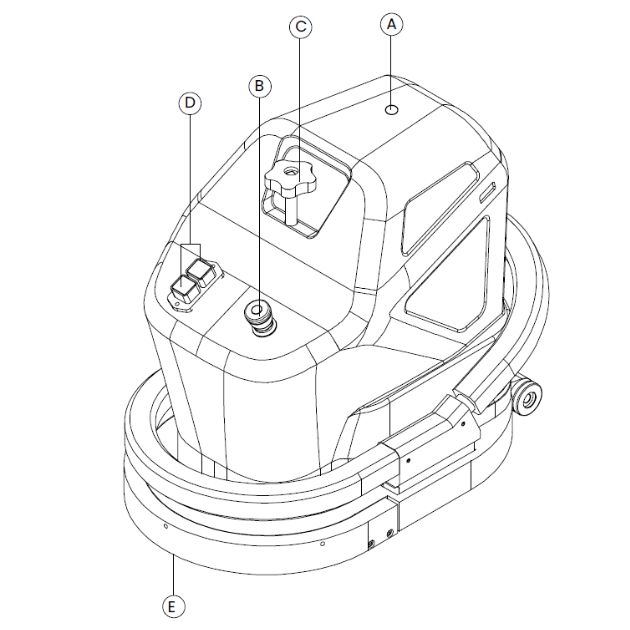

Detailed description

A- Electrical cable. the 48 volt current has to travel 6 metres long; the cable must always be connected to the central conversion unit by a special plug.

B- Stop button. Red stop switch is marked with “OFF” gives you the possibility to quickly turn off the machine even in an emergency.

C – Knob Z-Axis. The manual adjustment of the tool on the Z-axis via the practical knob makes the Master 4000 suitable for various types of work.

D – Start and Stop. Buttons to start and finish the processing easily and safely.

E- Water spray system. The machine is equipped with 4 adjustable water jets and a system for washing the surface which ensures that the bits cool down and that dust does not build up.

MASTER 4000

Packaging