MARMO SMART STATION

MARMO SMART STATION

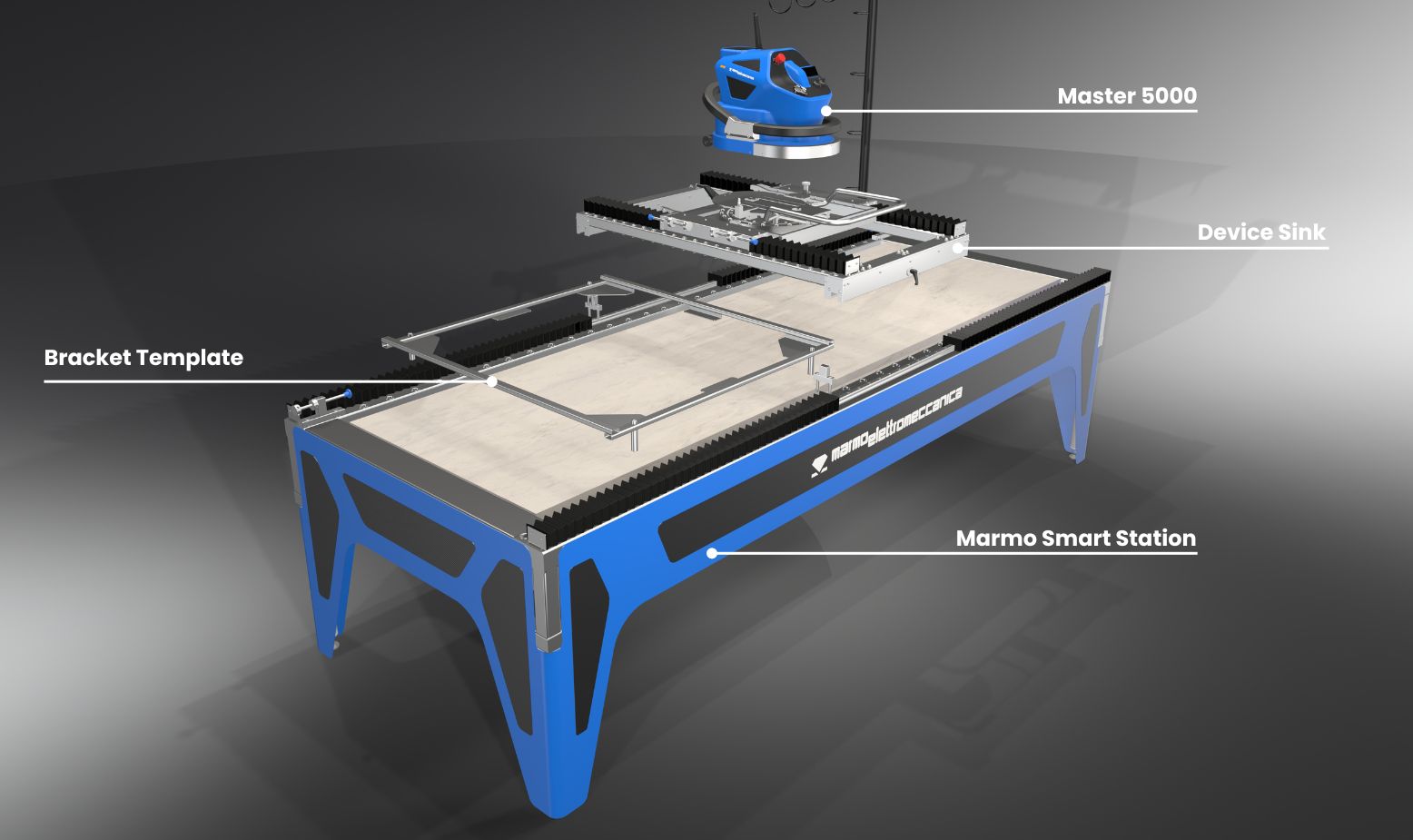

With over thirty years of excellence in the field of stone processing machines, we are proud to introduce the MARMO SMART STATION for the Master5000, a device that allows complete control over the contouring machine. The MARMO SMART STATION precisely manages all processing tasks: contouring, drilling, and polishing of marble, granite, and other stone materials. This Station combines the solidity of traditional methods with the latest technological innovations, meeting the needs of the most demanding professionals and ensuring unparalleled performance.

Why process with MARMO SMART STATION?

You don’t need a stationary CNC machine: the Device Sink with our Master 5000 replaces numerous needs in terms of both space and time. The new device allows cutting, polishing, and drilling of internal and external surfaces and profiles. It can shape complex contours with great precision on materials of any kind.

Profiling

Drilling

Sink Hole

Slab Polisher

Edge Polisher

45° Mitre

New special functions

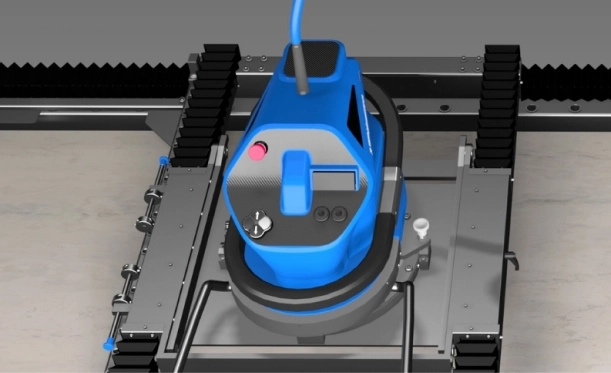

Master 5000

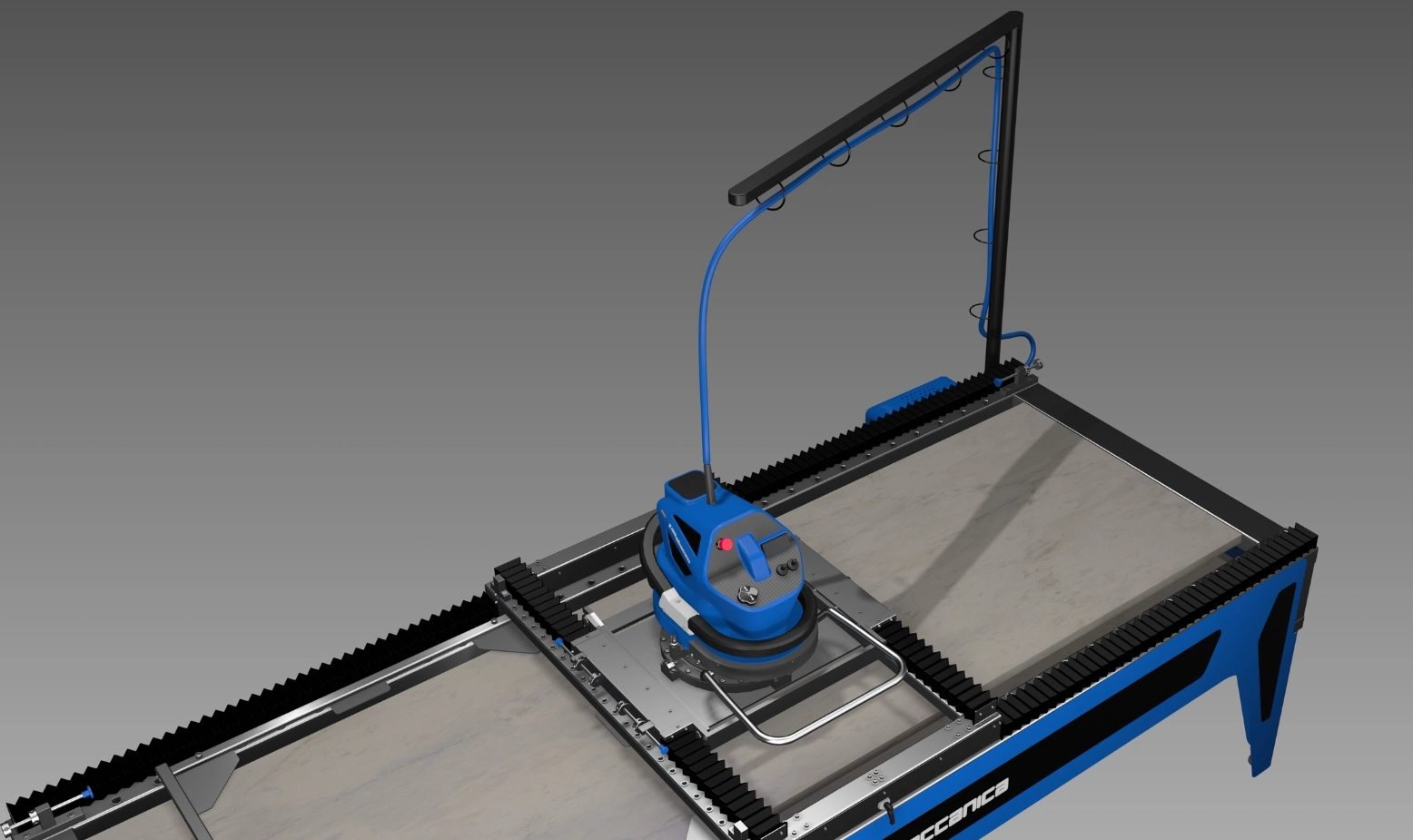

The new Marmoelettromeccanica manual contouring machine offers manufacturers the ability to work with any material in complex shapes, providing a high-quality product and significant time savings.

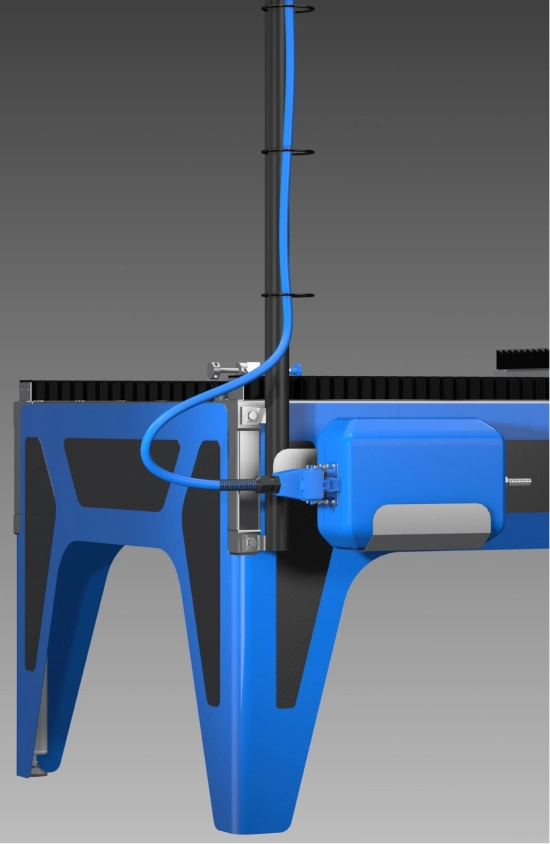

Mobile Frame

The mobile frame is designed to allow the horizontal movement of the Master 5000 machine on the workbench. Thanks to its precise and smooth sliding guides, the mobile frame enables quick and accurate positioning of the machine, optimizing operational efficiency and increasing production capabilities.

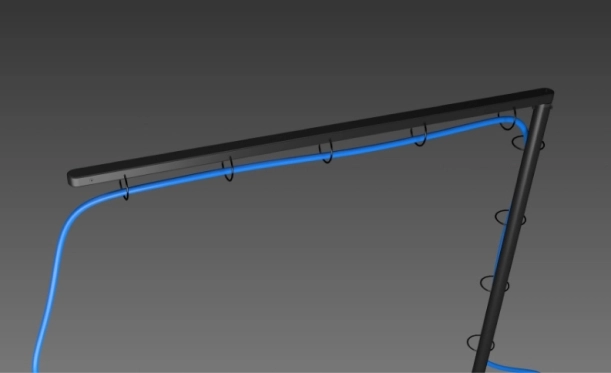

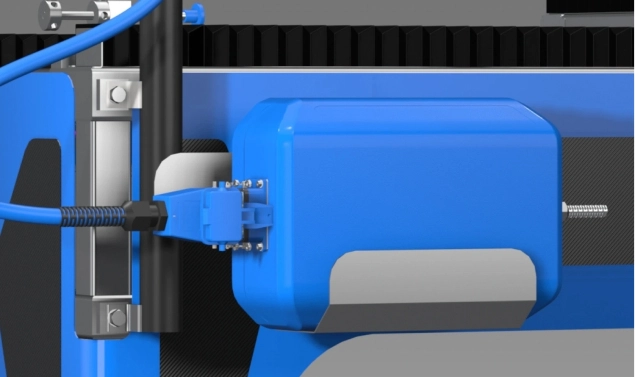

Sliding rod

The guide rod is designed to ensure the smooth movement of the machine’s water pipes and electrical cables without any hitches. Made of robust and durable material, this rod keeps the pipes and cables organized and protected, preventing tangles and damage. The rod’s design allows for easy installation and efficient operation, ensuring a constant and uninterrupted supply of water and electricity during the machine’s use.

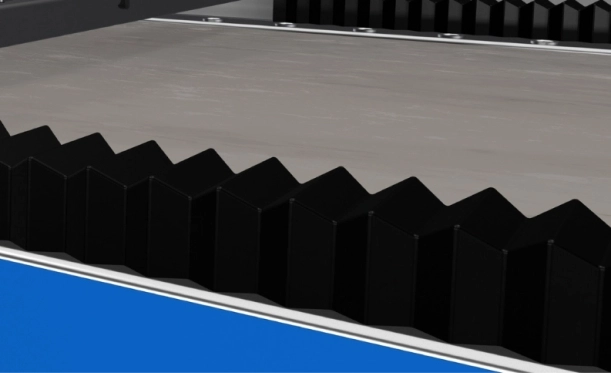

Guide Protection Bellows

Made from durable and flexible rubber, the bellows expands and contracts with the movement of the guides, providing continuous protection without hindering the machine’s operation. This essential component helps to extend the service life of the Device Sink, reduces wear, and minimizes the need for maintenance.

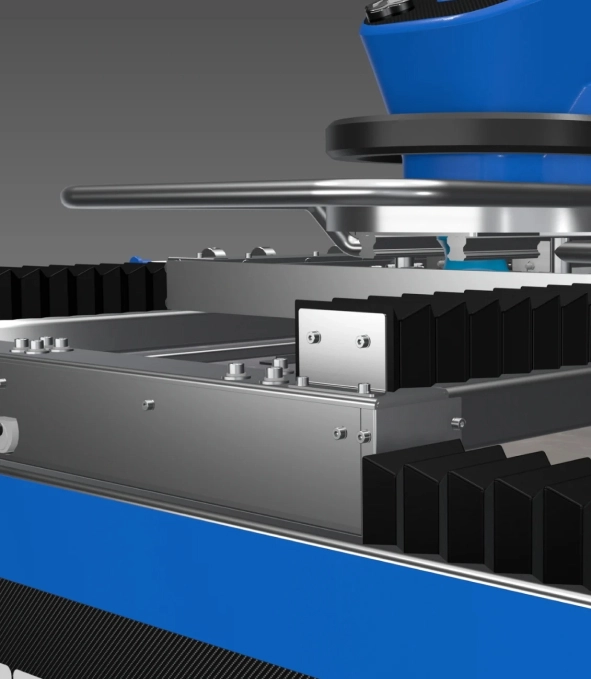

Blocks and constraints

Guide Handle

The guide handle of this machine for marble slab processing is designed to offer precise and easy control during operation. Made of metal, the guide handle allows the operator to maneuver the machine with precision, ensuring accurate and uniform movements. Despite its robustness, the ergonomic design of the handle ensures a comfortable and secure grip, reducing fatigue during prolonged use.

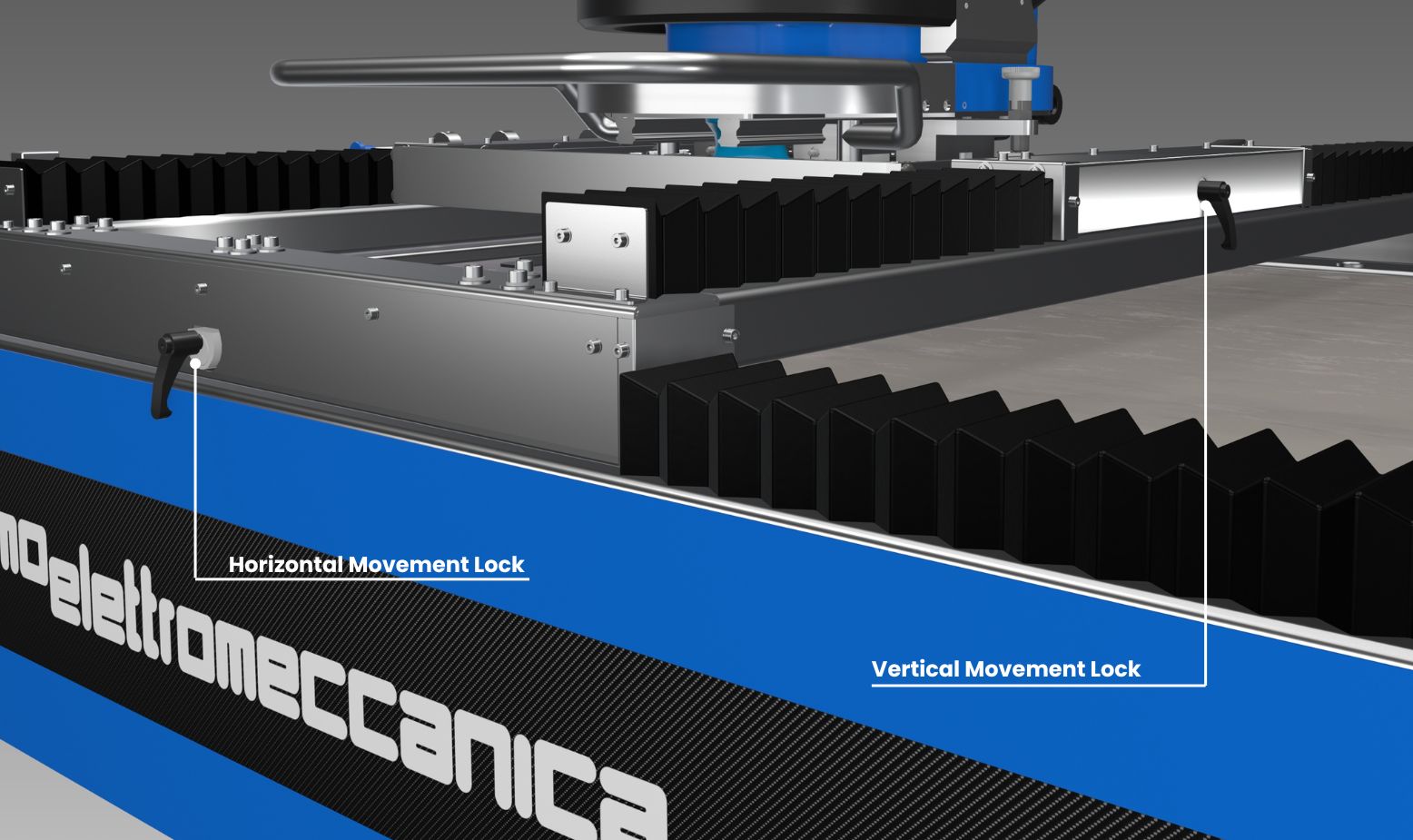

Master 5000 Lock: Horizontal and Vertical Movement

The locking knob is designed to immobilize the machine, allowing both horizontal and vertical work without errors. When activated, the knob securely locks the machine’s position, ensuring it remains stable during operation. This precise locking system enables operators to perform accurate, burr-free work, guaranteeing consistent and high-quality results. The knob is easy to use and designed for intuitive operation, providing reliable and safe control at every stage of the processing.

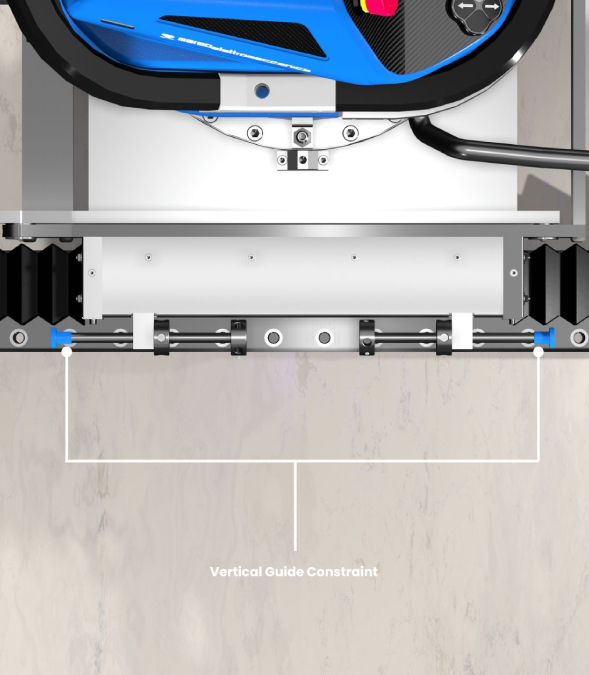

Vertical and Horizontal Guide Constraint

The guide constraint system is designed to lock a guide, preventing both vertical and horizontal movement of the machine. This locking system provides precise control over movements, ensuring that the machine remains firmly in position during operation. Thanks to this system, optimal results can be achieved, guaranteeing that work is carried out with maximum accuracy and stability.

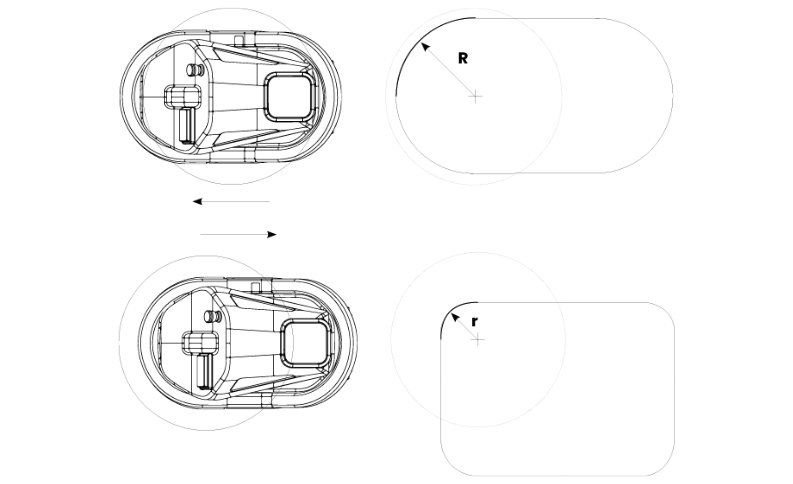

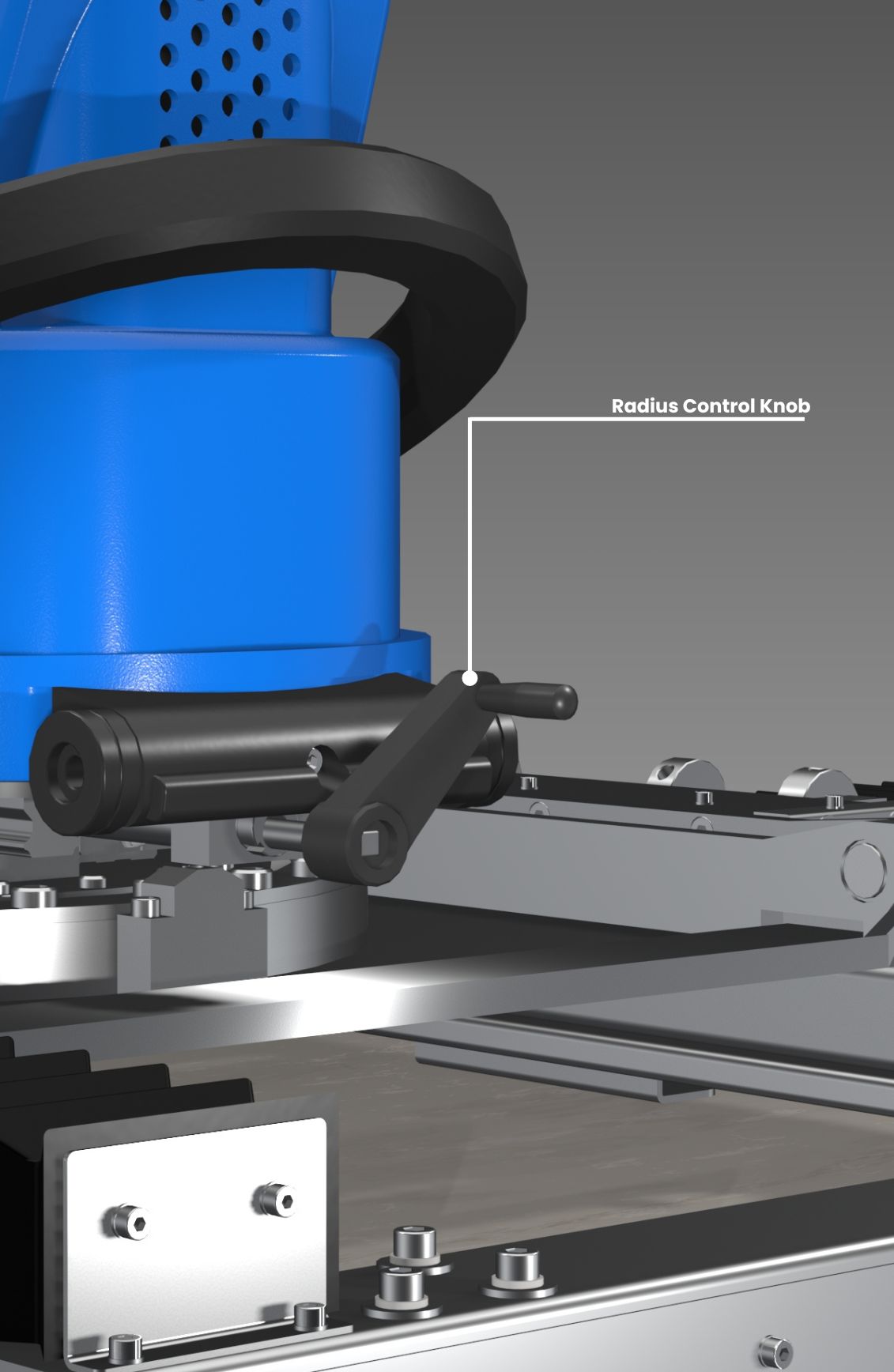

Radius Control Knob

The control knob, designed with a system for expanding and contracting, allows precise adjustment of the radius during operation. When the knob expands, the machine moves away from the center and works on a larger opening, resulting in a wider radius.

Conversely, when the knob contracts, the machine moves closer to the center, producing a smaller radius. This feature offers users precise and easy control of the radius size, allowing for greater versatility and accuracy in the processing.

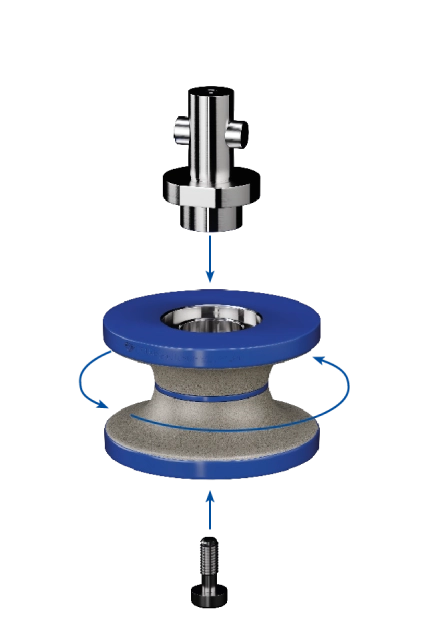

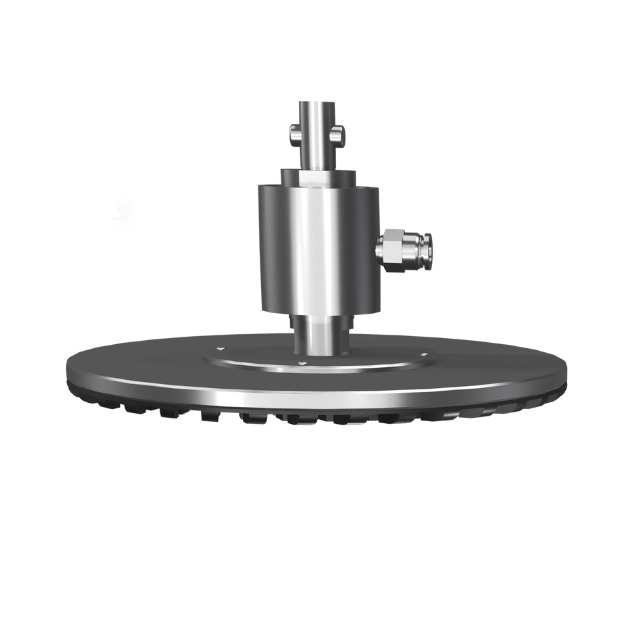

Quick-Connect Tool

The quick-release grinding cone is ideal for those seeking efficiency and speed. This component is designed to facilitate a quick and safe replacement of the grinding wheel, optimizing work times and increasing productivity in the workshop.

Tilting trolley

The tilting trolley for the MARMO SMART STATION represents an advanced solution for optimizing tool change processes. With its combination of robustness, safety, and ease of use, this component is a smart investment for any work environment that requires frequent tool changes.

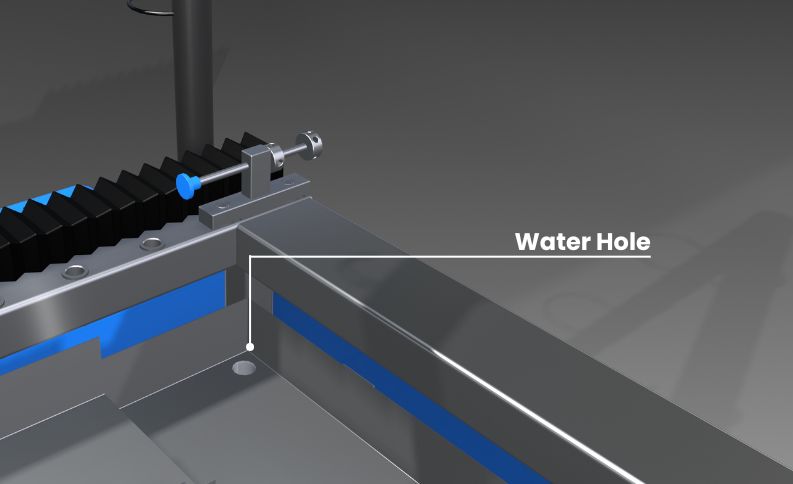

Water Hole

The hole, specially designed for water drainage, makes the MARMO SMART STATION compatible with wet enviroments and the ideal choice for sectors such as marble processing and other applications that require the presence of water during the process. This aspect is crucial for preventing injuries and ensuring workplace safety. It has been developed to ensure maximum stability and safety during use.

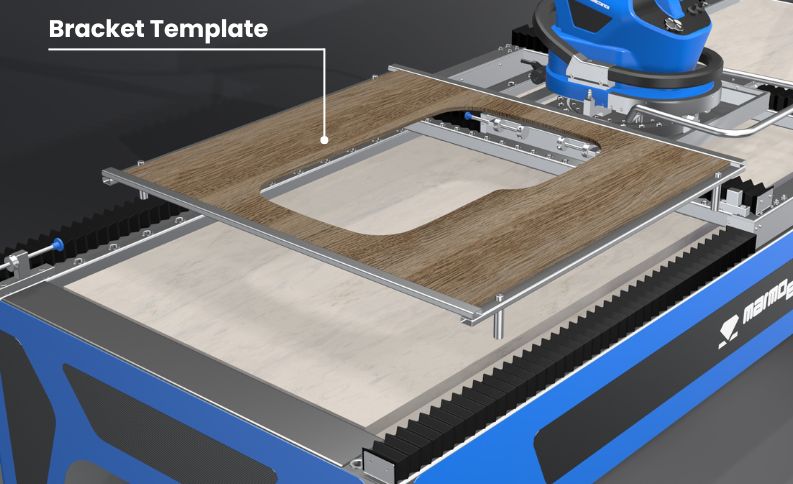

Bracket Template

Bracket Template is versatile frame allows for quick and secure positioning and fixing of the slab, enabling precise and customized cuts according to the specific project requirements. Equipped with a positioning and adjustment system, the mobile frame quickly adapts to different positions and thicknesses of the slab, ensuring stability, simplicity, and safety throughout the entire processing process.

Configuration and Device

The Marmo Smart Station requires a dedicated Work Station to ensure proper operation. To this basic configuration, a manual machine such as the Master 5000 can be added, thereby expanding operational capabilities. Additionally, the inclusion of supplementary equipment allows for a wider range of processes to be performed, offering a versatile and customizable solution for various production needs.

High Versatility and Power Machine

The control unit of the Master 5000 is designed to operate at voltages of 110 volts or 220 volts, making it suitable for use in any workshop or construction site. This versatility in power supply ensures that the machine can be easily integrated into various work environments without the need for special adapters or transformers.

The Master 5000 combines excellent power and operational flexibility, setting new standards of versatility and reliability in its field, and ensuring high-performance levels in every usage condition.

![]()

Dual Voltage Option

With the ability to function at both 110 volts and 220 volts, the machine offers unprecedented flexibility, easily adapting to both small artisan workshops and large industrial sites.

![]()

Guaranteed Power

A consumption of 1500W for 220 volts and 14Ah for 110 volts ensures that the machine has the necessary power for heavy and continuous operations, maintaining high standards of efficiency and productivity.

![]()

Ideal for Any Environment

Its ability to operate with different voltages makes it ideal for international use, overcoming barriers that often limit the use of heavy machinery due to local power specifications.

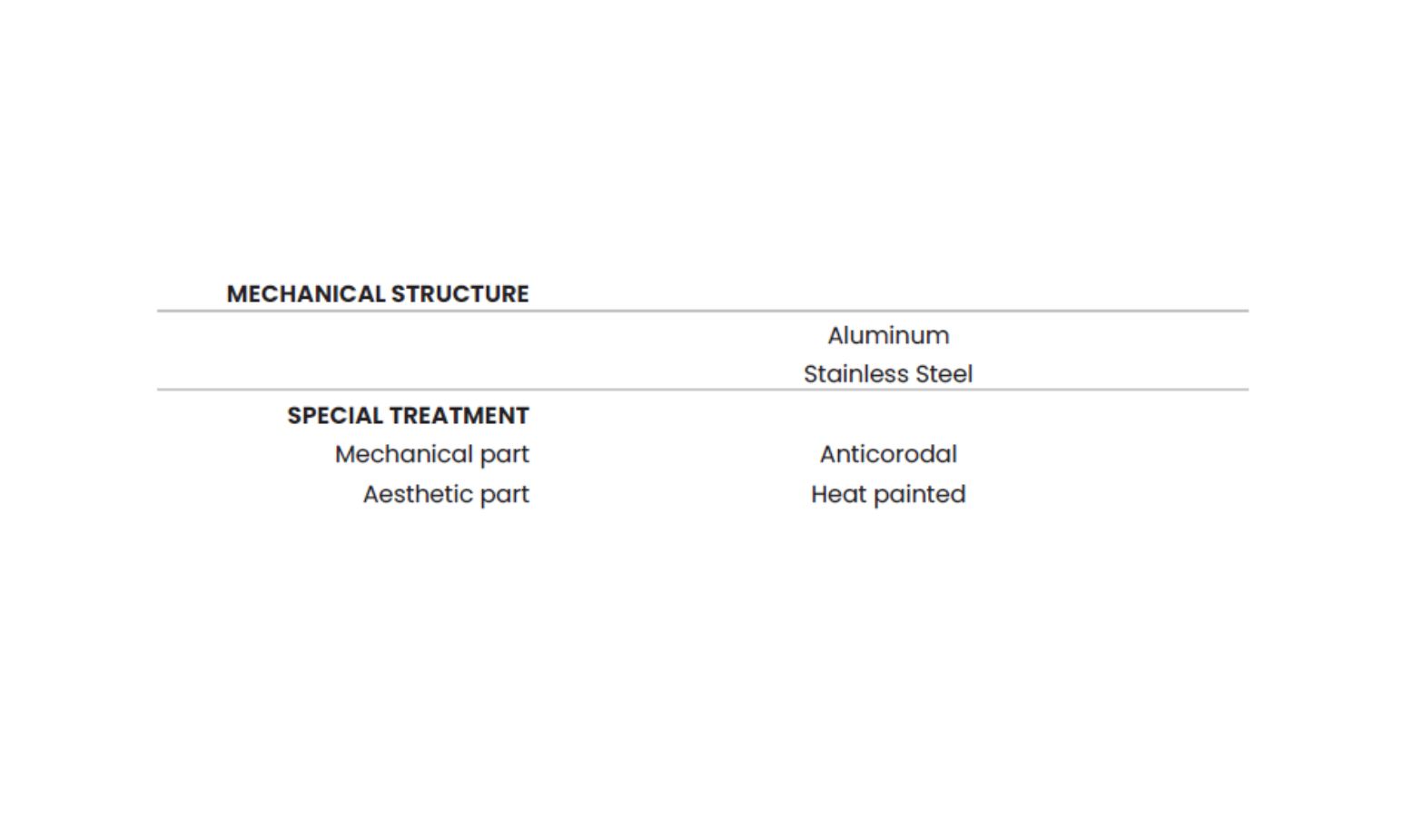

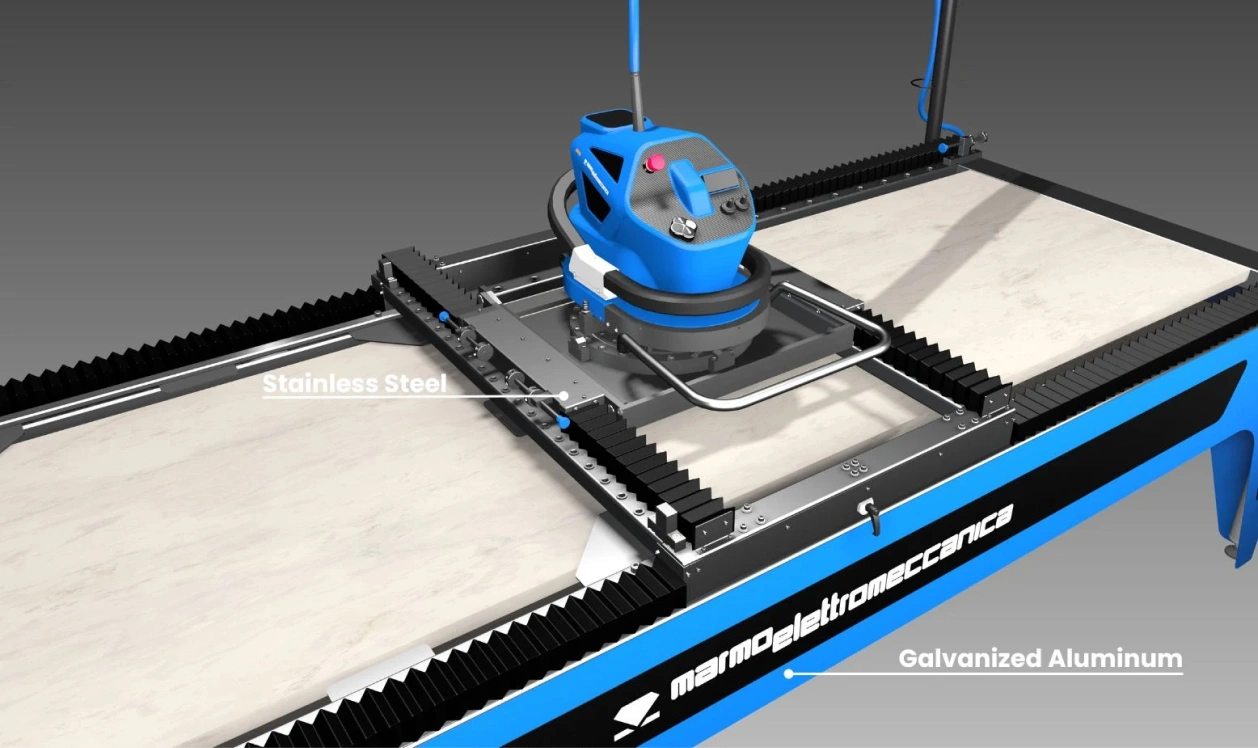

MARMO SMART STATION:

Built to Last

The MARMO SMART STATION is entirely constructed from stainless steel and galvanized aluminum, materials chosen to ensure maximum durability and resistance over time. This combination also provides superior resistance to corrosion, wear, and environmental stress.

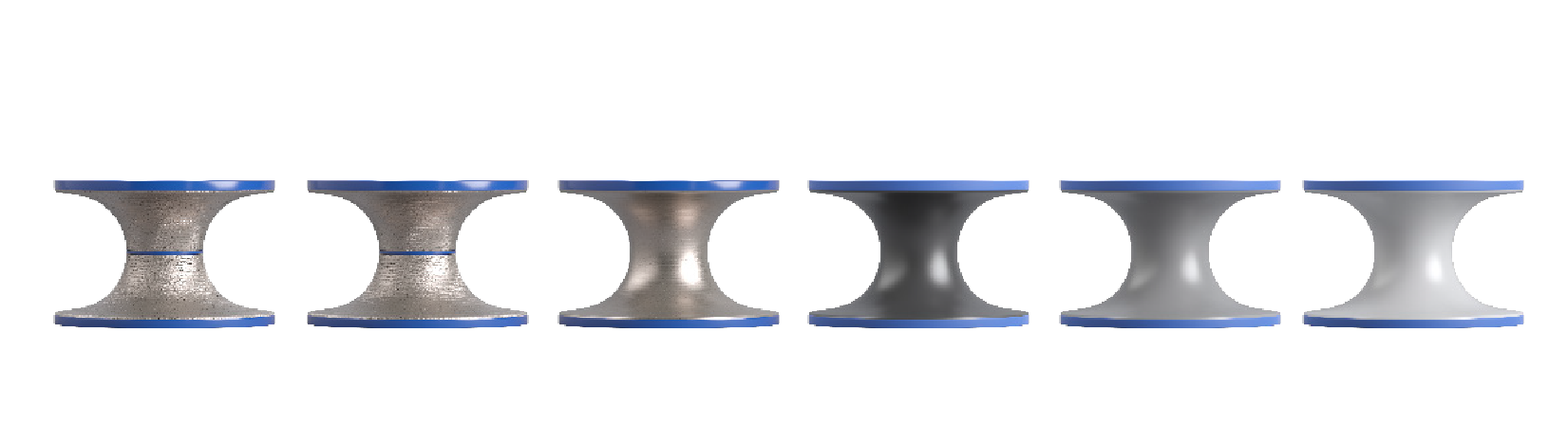

Work Steps for

internal and external profiling

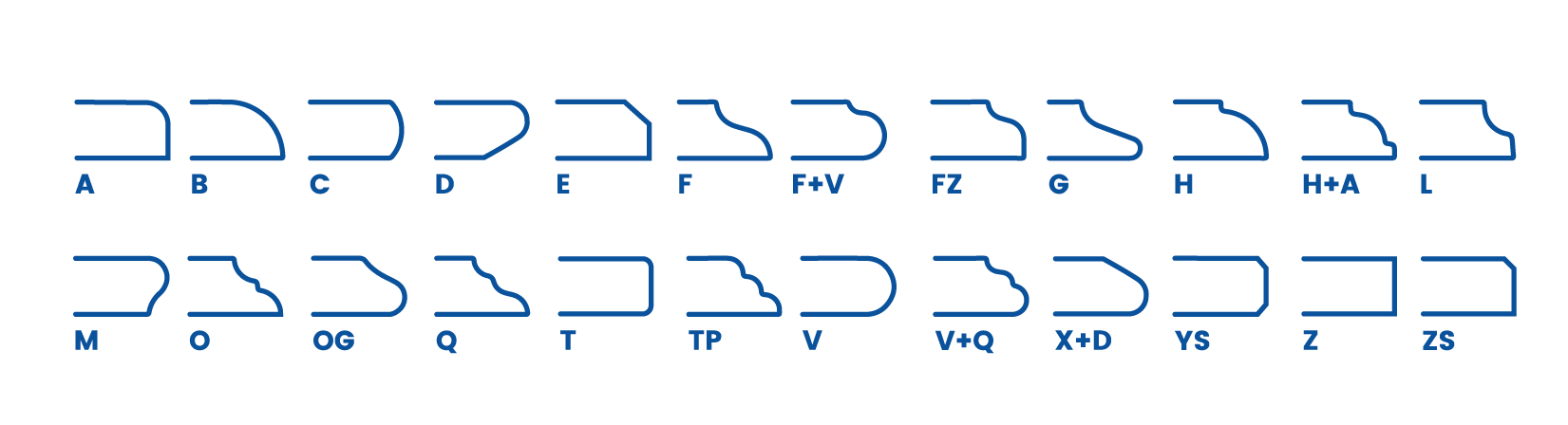

From Quick Contouring to Perfect Polishing

For every edge in granite, quartz, ceramic, marble, and other materials, our technology allows for a transition from rapid contouring to impeccable polishing. With over 200 standard profiles available in stock, the possibilities for customization are endless.Furthermore, we create profiles based on specific customer requests, ensuring tailor-made solutions for every need.

STEP 1 – Profiling

STEP 2 – Polishing

Work Steps for

Sink Hole

Drilling and Cutting with Marmo Smart Station

The Marmo Smart Station with the Master 5000 enables the use of drill bits for drilling and end mills for precise cutting. Thanks to the Smart Station, the Master 5000 is even more versatile and suitable for meeting every specific processing requirement.

Designed for Kitchen Countertop Fabrication

Thanks to the possibility of installing 20 mm grinding wheels with a half-gas attachment on the Master 5000, the Smart Station allows the creation of internal holes up to a radius of 10 mm, from roughing to perfect polishing.

STEP 1 – Hole

STEP 2 – Cut

STEP 3 – Profiling

STEP 4 – Polishing

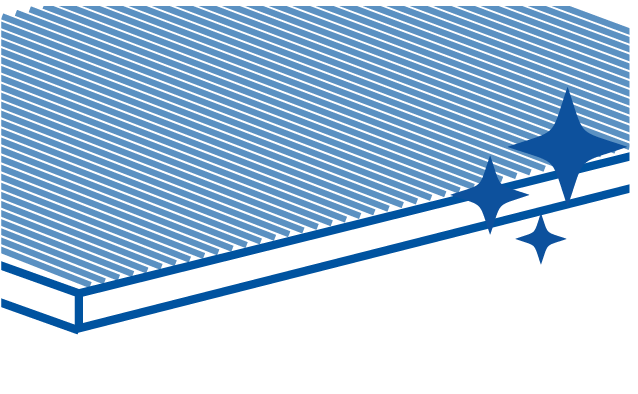

Work Steps for:

Polishing Slabs

Polishing, smoothing and brushing finishes

Thanks to the Marmo Smart Station and the Master5000, with the use of a dedicated accessory, it is possible to polish, smooth, and brush slabs of a wide range of materials such as marble, granite, travertine, and limestone with ease and speed. The versatility of the accessory allows operators to quickly adapt to different finishing needs, significantly increasing the efficiency of the workshop.

STEP 1 – Metal Diamond Plate

STEP 2 – Polishing Diamond Plate

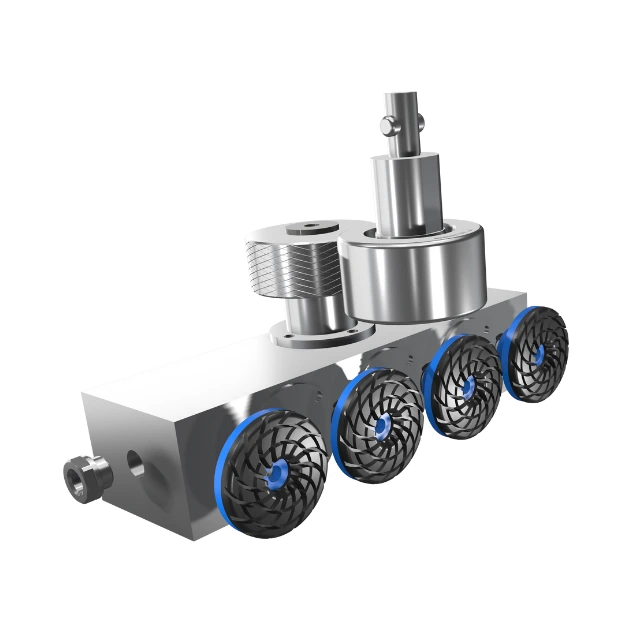

Work Steps for

Inline Polishing

Polishing on the straight edge in a single pass

Equipped with a special head that mounts four tools, the Smart Station worktop and the Master5000 allow for the polishing of various materials on the straight edge in a single pass. This configuration not only ensures an impeccable finish but also offers significant time savings. With the Master5000, you can replace manual polishing processes with an automatic, efficient, and highly productive solution.

ONLY ONE STEP – From Grinding to Polishing

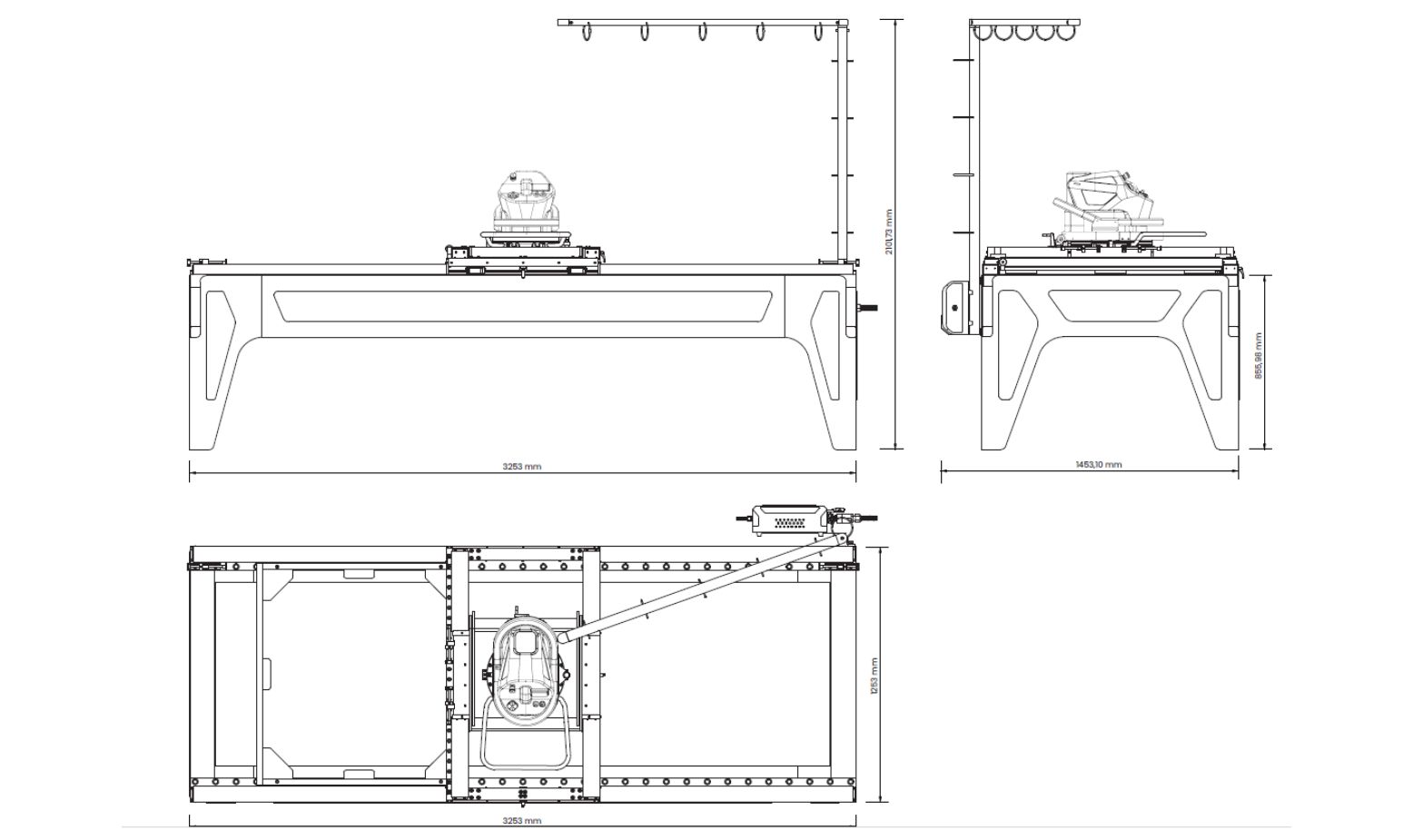

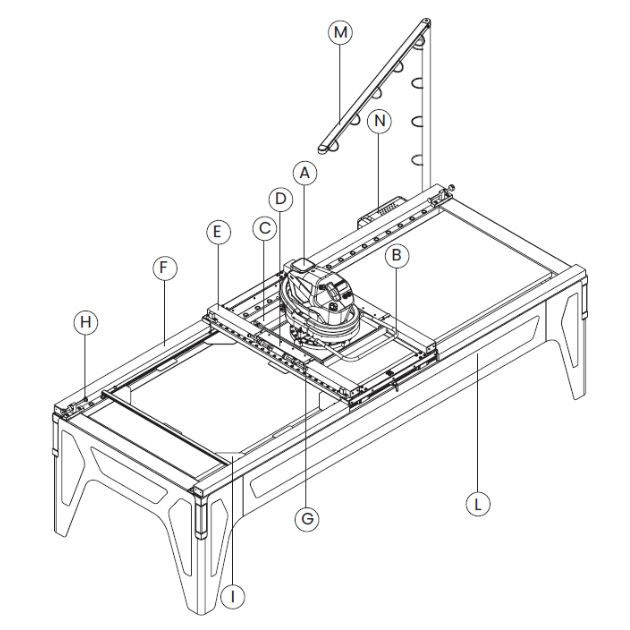

Technical Drawing

MARMO SMART STATION

Detailed description

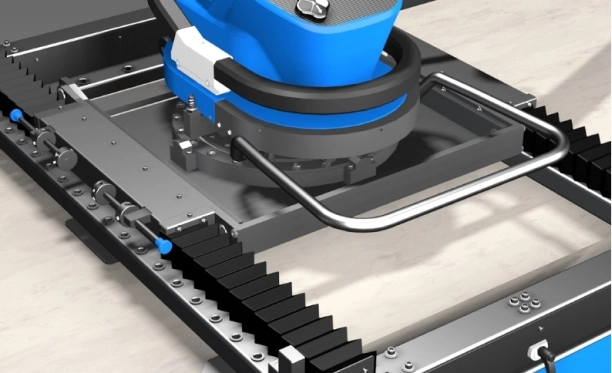

A- Master 5000.T he new Marmoelettromeccanica manual contouring machine.

B- Guide handle. Made of metal, the guide handle allows the operator to maneuver the machine with precision, ensuring accurate and uniform movements.

C – Tilting trolley. Made of stainless steel, it allows for quick tool changes thanks to its rotary movement.

D – Mobile frame. Designed to allow the horizontal movement of the Master 5000 machine on the workbench, this robust frame is made of stainless steel to ensure stability and durability over time.

E- Rubber bellows for vertical guide. Designed to cushion and smooth vertical movements during the machining process.

F- Rubber bellows for horizontal guide. Designed to cushion and smooth horizontal movements during the machining process.

G- Vertical Guide Constraint. This locking system provides precise control over movements, ensuring the machine remains firmly in position during operation.

H- Horizontal Guide Constraint. This locking system provides precise control over movements, ensuring the machine remains firmly in position during operation.

I- Versatile frame. It allows for quick and secure positioning and fixing of the slab, enabling precise and customized cuts according to the specific project requirements.

L- Workbench. Supporting structure made of galvanized aluminum, painted with carbon inserts.

M- Housing for electrical control unit. The dedicated housing allows for the safe positioning of the power supply.

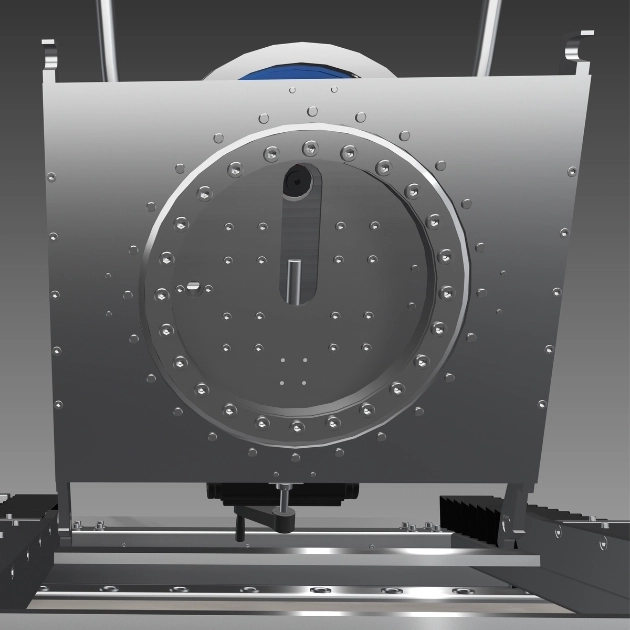

MARMO SMART STATION