Flat Edge

Flat Edge

Tools specially designed for straight edge polishing that have been engineered to achieve perfect polish. With discharge channels specifically designed for optimal tool lubrication, they enable flawless straight-edge polishing without any form of streaking, guaranteeing perfect shine and exceptional durability. These innovative tools embody precision and efficiency, transforming the process of straight-edge polishing into a smooth and effective operation. Their unique design not only guarantees superior shine but also extends the life of the tool, making it a valuable asset for any manufacturing process.

Embrace the ultimate solution for straight-edge polishing and experience unmatched polish quality, enhanced durability, and a significant reduction in operational downtime. Our commitment to innovation and excellence ensures that you achieve the best possible finish on every straight edge, setting new standards in the industry.

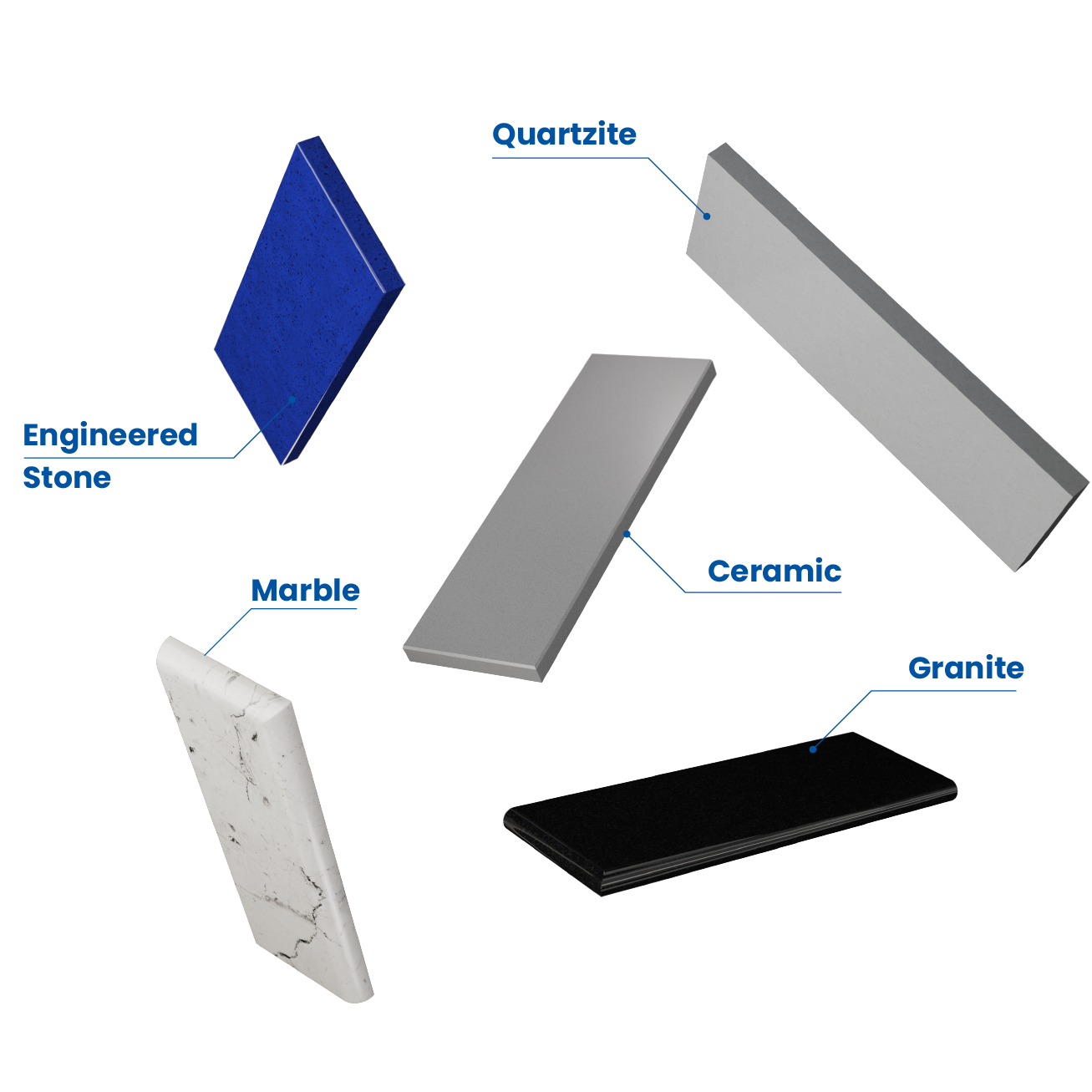

A single product for all materials

Discover unprecedented compatibility with the new Inline Polishing Pads – the only product you’ll need for all materials. This cutting-edge technology is the epitome of versatility, allowing smooth work on a wide range of materials, both natural and artificial. Specifically designed for marble, granite, limestone, quartzite, engineered stone, and ceramic, it offers a unique solution that revolutionizes the polishing process.

Our unique product eliminates the need to swap tools for different materials, allowing the same tool to effortlessly transition between various types of stone and ceramics. This not only saves significant time on machine setup but also increases production flexibility. Now, you no longer need to change tools; with just one type of pad, you can work on all materials consecutively. Embrace the future of material processing where simplicity meets efficiency.

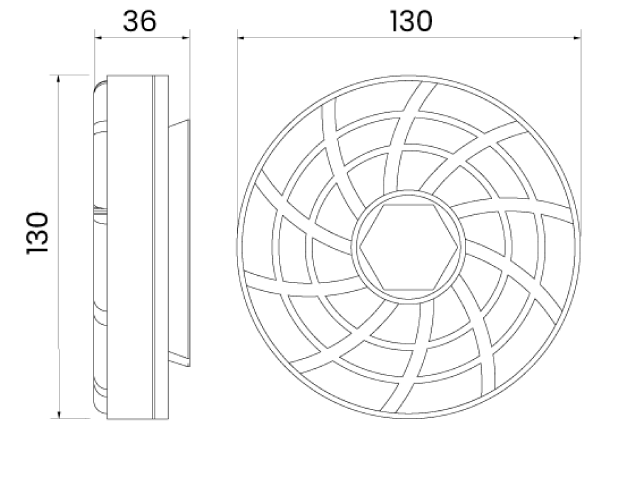

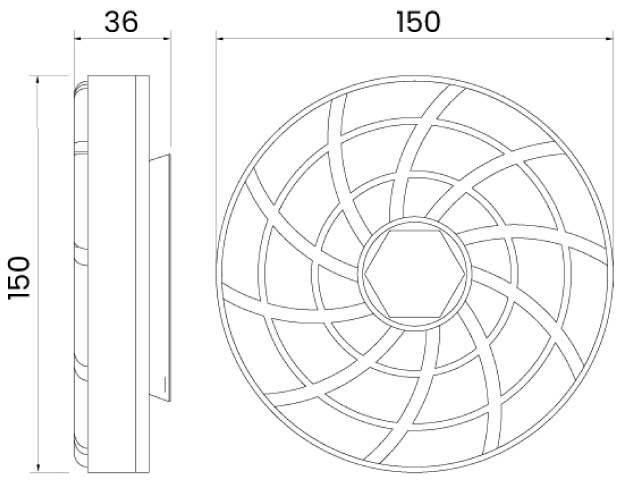

Available Diameters

Ø 130mm / 5”

Ø 150mm / 6”

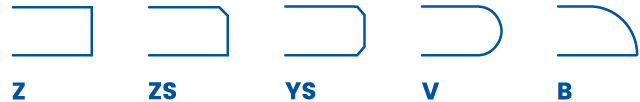

Profiles

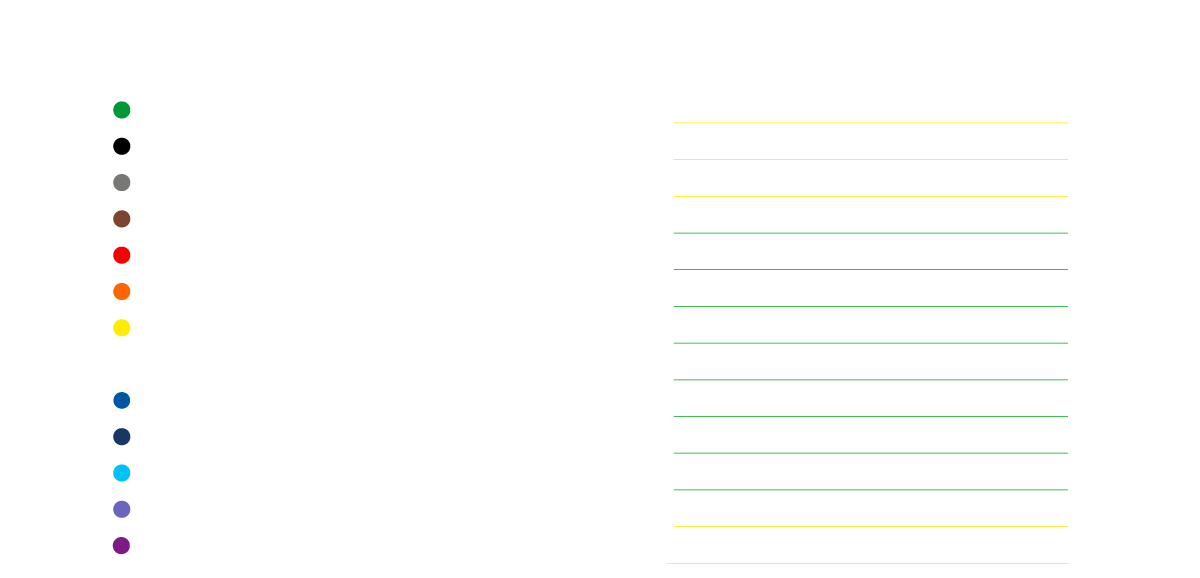

Sequence

The table provides guidance on the indicative sequence for the Inline Polishing Pads.

However, adjustments may be necessary depending on the specific type of material and machine. Additionally, it’s possible to sequence two identical grits to further increase speed.

For machines with more than eight heads, the choice of grits, in addition to those required for polishing, depends on the desired outcome.

Our technical department is fully available to advise you on the right sequence for your machine.